Sieno — Your Trusted Freeze Drying Equipment Expert A leading manufacturer of vacuum freeze drying equipment and cold chain solutions, with over two decades of professional experience in the refrigeration industry.

Global Reach: Our products are trusted by customers in Europe, Asia, the Americas, and beyond. We proudly partner with top-tier freeze-dried food producers worldwide

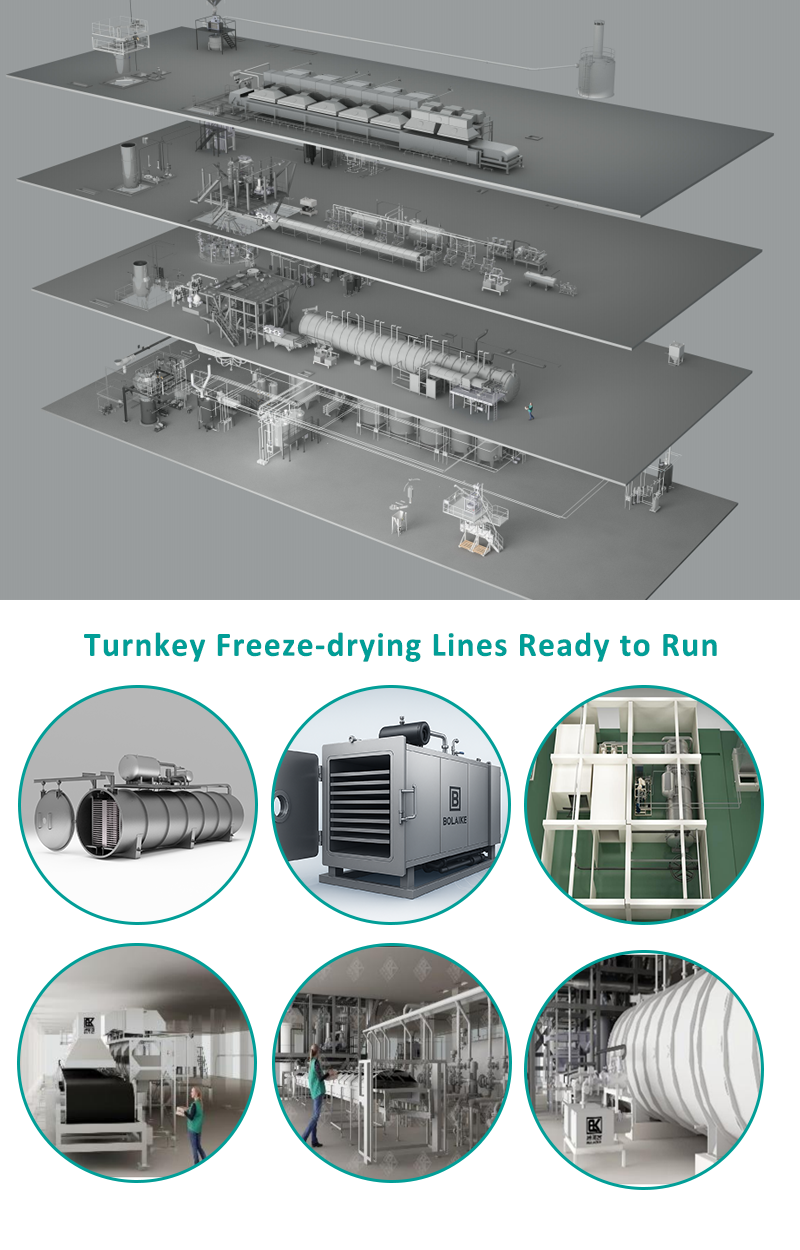

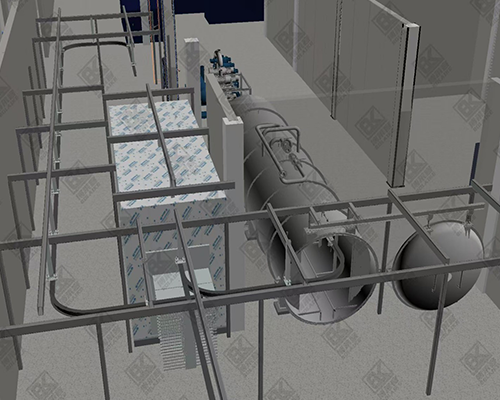

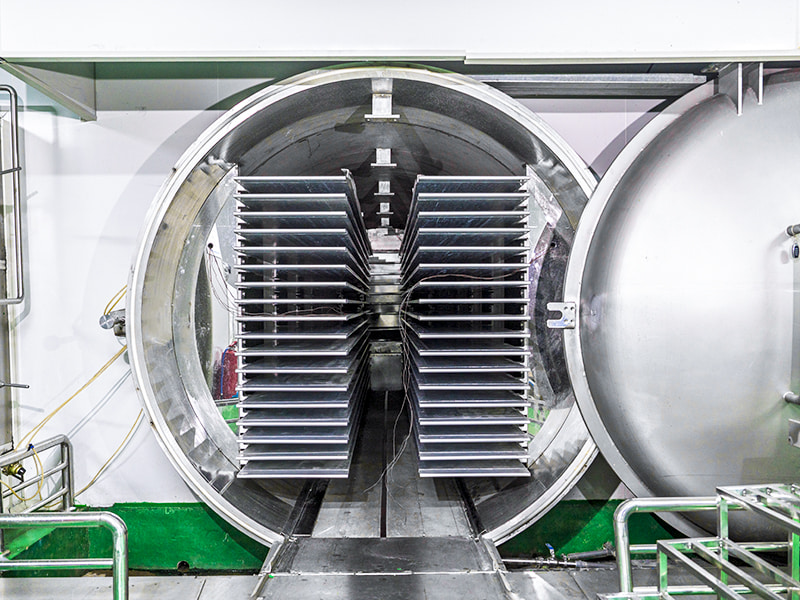

One-Stop Solution: From custom design to production and installation, we offer complete, turnkey solutions.

Factory Size: 12,000㎡ production base, 120+ employees

Certifications: ISO9001 | CE Certified

Innovation Leader: 56+ national patents

What We Freeze Dry: Food | Vegetables | Fruits | Coffee | Flowers | Herbal Extracts | Seafood | Nutraceuticals | Biological & Chemical Products

Leveraging our independently developed intelligent freeze-drying equipment and tailored solutions, we offer comprehensive technical support to food enterprises, spanning from raw material processing to finished product packaging, empowering clients to achieve efficiency gains, quality upgrades, and the multifaceted values of environmental sustainability.