One of the fundamental challenges in freeze-drying seeds and fungi is maintaining their delicate biological structures. Seeds, for example, need to preserve their viability for future germination, while fungi must retain their bioactive compounds, which are vital for their medicinal properties. The innovative design of modern freeze-drying equipment focuses on precision in temperature and pressure control, which is crucial for optimizing the drying process. Traditional freeze-drying systems operated with less advanced control mechanisms, which meant that operators had to rely on trial and error to find the optimal settings. However, innovations in temperature and pressure control have brought a level of precision that allows for automated adjustments based on real-time conditions. This reduces the risk of damage to seeds and fungi during the freeze-drying cycle. Through the use of advanced sensors and control algorithms, modern freeze-drying equipment can now adjust temperatures and pressures at a granular level, ensuring that seeds remain viable, and fungi retain their medicinal properties. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd., with its dedication to the integration of intelligent equipment manufacturing, excels in providing systems that adapt to the varying needs of different agricultural and food sectors. The company’s equipment is tailored to maintain precise environmental conditions, ensuring that the freeze-drying process is both efficient and gentle on the materials.

Energy efficiency has become a significant focus in the design of modern freeze-drying equipment. Freeze-drying, in general, requires substantial energy, particularly when large quantities of materials such as seeds or fungi are being processed. Traditional freeze-drying machines operated with less efficient energy use, leading to high operational costs and a larger environmental footprint. Innovative designs now incorporate energy-saving technologies that help to optimize energy consumption during the freeze-drying cycle. Key innovations in this regard include the development of improved insulation materials, optimized heat recovery systems, and more efficient compressors. These systems recover heat that would otherwise be wasted and recycle it back into the drying process, significantly lowering energy costs. For instance, high-efficiency heat exchangers, integrated with modern freeze-drying equipment, are capable of recovering and reusing energy throughout the process. This not only reduces the need for external energy sources but also minimizes the carbon footprint of operations. These advancements help reduce the overall costs of freeze-drying, which is particularly important for industries that deal with high volumes of perishable materials such as seeds and fungus. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. integrates these energy-efficient solutions into their equipment designs, ensuring that clients can achieve cost savings while contributing to environmental sustainability. The company's focus on cutting-edge energy management technologies sets its freeze-drying systems apart in an increasingly energy-conscious market.

Different materials, such as seeds and various types of fungi, require unique conditions for optimal freeze-drying. The structural integrity of seeds, for example, depends heavily on the precise control of freezing temperatures and the rate of sublimation. On the other hand, different fungi may have varying moisture content, texture, and bioactive compounds, necessitating specialized equipment. To address these variations, innovative freeze-drying equipment now comes with customization options that allow the settings to be finely tuned for specific materials. Customizable parameters include temperature profiles, pressure settings, and drying time, all of which are critical in preserving the characteristics of delicate materials like seeds and fungi. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. provides highly customizable solutions tailored to the specific needs of its clients. The company's focus on precision engineering means that its freeze-drying systems can be adapted to optimize the drying process for different seed varieties and fungal species, ensuring that each material is processed under the ideal conditions.

Artificial intelligence (AI) is revolutionizing industries by enabling more intelligent, autonomous systems. In the realm of freeze-drying, AI is playing an increasingly prominent role. Through machine learning algorithms and real-time data analysis, AI can now be used to optimize the freeze-drying cycle, adjusting parameters dynamically based on input from sensors embedded within the equipment. AI-enhanced freeze-drying systems are capable of learning from past drying cycles to predict and adjust variables such as temperature, pressure, and time. This makes the freeze-drying process more efficient, reducing both waste and energy consumption. Furthermore, AI systems can detect anomalies during the freeze-drying process and automatically adjust the equipment to prevent errors that could lead to poor-quality products. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. has been at the forefront of this technological integration, incorporating AI-driven optimization features into its freeze-drying equipment. These intelligent systems not only increase efficiency but also ensure that the highest quality standards are met in the preservation of seeds and fungi.

Automation has been a key driver of efficiency in modern manufacturing, and the freeze-drying industry is no exception. Today’s freeze-drying equipment is designed to be fully automated, which means that operators no longer need to manually adjust settings during the drying process. Automation allows for continuous monitoring, adjusting, and fine-tuning of parameters without direct human intervention. The integration of remote monitoring systems has allowed for greater flexibility and oversight in freeze-drying operations. Through connected devices and Internet of Things (IoT) technology, operators can monitor the status of freeze-drying equipment remotely, receiving real-time updates on key performance indicators such as cycle progress, energy usage, and temperature fluctuations. This level of control is especially valuable in large-scale processing plants where the freeze-drying of seeds and fungi may involve numerous units operating simultaneously. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. offers advanced automation and remote monitoring systems, ensuring that clients can manage their freeze-drying processes more effectively. By combining automated cycle control with remote monitoring, the company provides a comprehensive solution that boosts productivity while minimizing the risk of human error.

One of the latest innovations in freeze-drying technology is the development of multi-layered drying systems, which allow for higher throughput and more efficient processing of large volumes of material. Traditional freeze-drying systems were limited in their capacity due to the sequential nature of the process, where each layer of material had to be dried individually. However, multi-layered systems allow for simultaneous drying of multiple layers of seeds or fungi, significantly increasing throughput. This innovation not only reduces processing times but also improves the overall efficiency of the freeze-drying process, making it more scalable for larger operations. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. has developed multi-layered freeze-drying equipment that improves throughput without sacrificing product quality. This innovation is particularly beneficial for industries that need to process large quantities of seeds or fungi quickly while ensuring consistent, high-quality results.

Vacuum-assisted freeze-drying is another innovation that has been incorporated into modern equipment designs. By optimizing the vacuum environment, this process enhances the sublimation rate, leading to faster drying cycles while maintaining the structural integrity of the material. For seeds and fungi, this method is especially effective because it helps preserve the biological structure of these materials, ensuring that they maintain their potency, viability, and other essential qualities. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. employs vacuum-assisted freeze-drying technology in its equipment, offering clients an advanced method for faster processing with better material preservation. By applying this technology, the company’s systems help ensure that seeds and fungi retain their full range of qualities, from germination ability to medicinal efficacy.

Heat exchange systems are integral to any freeze-drying process, as they play a crucial role in maintaining the necessary temperature gradients throughout the cycle. Traditional systems often struggled with maintaining uniform heat distribution, leading to inefficiencies in the drying process. However, with the latest advancements in heat exchange technology, modern freeze-drying equipment ensures that heat is distributed more evenly, improving both efficiency and quality. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. incorporates advanced heat exchange systems in its freeze-drying equipment, ensuring that seeds and fungi are processed efficiently without the risk of overheating or uneven drying. The company’s commitment to optimizing heat management helps to reduce energy costs while improving overall drying performance.

Deep Freezer for Seed & Fungus

Deep Freezer for Seed & Fungus

Vacuum Aluminum Foil Packaging Machine for Seed & Fungus

Vacuum Aluminum Foil Packaging Machine for Seed & Fungus

Conductivity Meter for Seed & Fungus

Conductivity Meter for Seed & Fungus

Colony Counter for Seed & Fungus

Colony Counter for Seed & Fungus

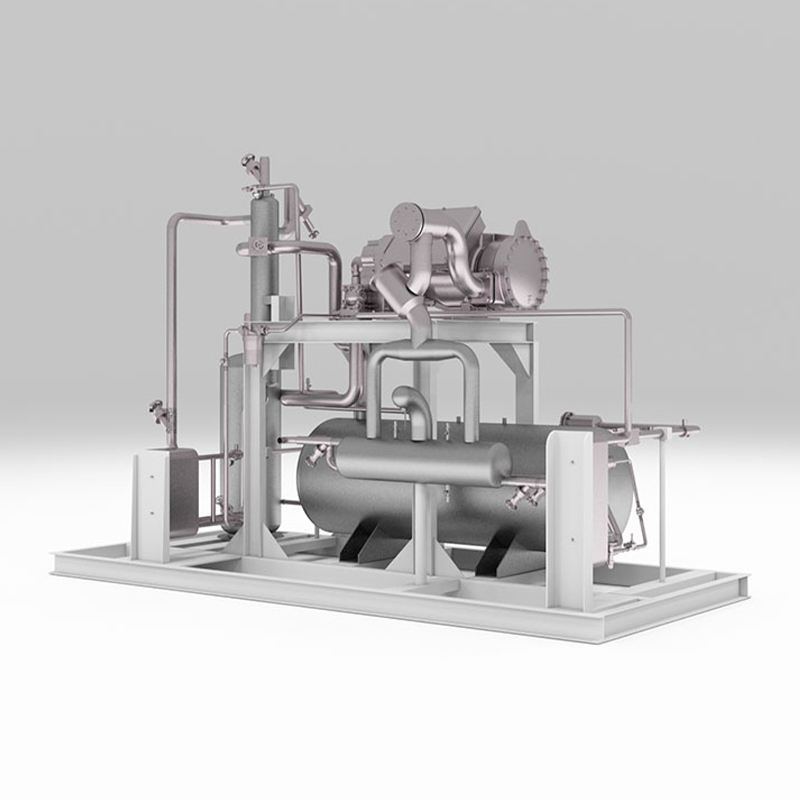

Vacuum Freeze Dryer for Seed & Fungus

Vacuum Freeze Dryer for Seed & Fungus

Ultrasonic Wall Breaker for Seed & Fungus

Ultrasonic Wall Breaker for Seed & Fungus

Programmable Cooling Device for Seed & Fungus

Programmable Cooling Device for Seed & Fungus

Aseptic Centrifuge for Seed & Fungus

Aseptic Centrifuge for Seed & Fungus