What are the key factors to consider when selecting freeze-drying equipment for fragrance products?

Choosing the right freeze-drying equipment for fragrance products is crucial for the production of fragrance products because the process directly affects the quality, stability and cost-effectiveness of the fragrance. When selecting equipment, several factors need to be considered:

(1) Size and capacity of the freeze-drying chamber

Product scale: Depending on the scale of production, the size and capacity of the freeze-drying equipment for fragrance products need to be adjusted. Small-scale production is suitable for smaller equipment, while large-scale production requires greater processing capacity. The size of the equipment should be able to meet the processing requirements of each batch of fragrance without wasting space and energy.

Product type: Different types of fragrances (such as liquid, solid or powder) will have different requirements for the size and function of the equipment. Liquid fragrances may require more delicate freezing and sublimation processes, while solid fragrances may require longer drying times or more powerful cooling systems.

(2) Temperature control accuracy

Freezing temperature: Freeze-drying equipment for fragrance products needs to precisely control the freezing temperature to ensure that the volatile components of the fragrance will not be degraded due to too low or too high temperatures. Too low a temperature will cause the fragrance components to crystallize too quickly, affecting the fragrance release of the product; too high a temperature may destroy the molecular structure of the fragrance, resulting in the loss of fragrance.

Sublimation temperature: Temperature control during the sublimation stage is crucial. The volatile components in fragrances are often very sensitive, so it is necessary to ensure a balance between the volatilization rate of the fragrance components and the temperature during the sublimation process to avoid the loss of fragrance.

(3) Pressure control

Vacuum degree: The freeze-drying process needs to be carried out under low pressure (vacuum) to ensure that ice crystals can directly sublimate into water vapor without passing through the liquid stage. The performance of the equipment's vacuum pump and pressure sensor directly affects the entire freeze-drying effect. For fragrances, changes in pressure will affect the preservation of volatile components.

Pressure control accuracy: Excessive pressure fluctuations may cause changes in the molecular structure of the fragrance, affecting the concentration and persistence of the final fragrance. Freeze-drying equipment for fragrance products needs to have a precise pressure control system to ensure that the fragrance products can stably preserve their fragrance components throughout the entire process.

(4) Climate and humidity control

Environmental conditions: Freeze-drying equipment for fragrance products also needs to consider the temperature and humidity of the production environment. In a high humidity environment, fragrances may absorb moisture, which will affect their stability. Especially in a high temperature and high humidity environment, the drying effect of the freeze drying system may be limited, so it is necessary to ensure that the equipment can adapt to different climate conditions.

Air circulation: The equipment needs to have a good air circulation system to promote gas exchange during the sublimation process and effectively remove water vapor.

(5) Corrosion resistance of materials and equipment

The ingredients in fragrance products are often corrosive or volatile, so the material selection of the equipment is very important. The interior of the equipment needs to be made of materials that are corrosion-resistant, high temperature-resistant, and will not react with the fragrance ingredients to prevent chemical reactions between the materials and the fragrance, resulting in fragrance changes or equipment damage.

(6) Energy efficiency and cost-effectiveness of the equipment

Energy consumption: Freeze drying is a high-energy consumption process, so the energy efficiency of the equipment is very critical. Choosing equipment with high energy efficiency and low operating costs can significantly reduce production costs. Maintenance and operation: Whether the equipment's operating interface is user-friendly and whether maintenance is convenient are also factors to consider when selecting equipment. The equipment's failure rate and maintenance cost directly affect the company's production efficiency and cost.

What effect does the freeze-drying process have on the chemical stability of fragrance oils?

The freeze-drying process removes moisture from fragrances through low temperature and low pressure, but this process also has a profound impact on the chemical stability of fragrance oils, mainly reflected in the following aspects:

(1) Loss of volatile components

Fragrance oils contain a large number of volatile components, which determine the concentration and persistence of the fragrance. During the freeze-drying process, sublimation (direct conversion of solid to gas) causes some volatile components to evaporate along with the gas, especially low-boiling-point chemical components. This may lead to changes in the fragrance, weakening of the fragrance intensity, and even changes in the fragrance characteristics. The aroma molecular structure of fragrance oils is usually more complex, including aromatic molecules, esters, alcohols and other chemical substances. Temperature fluctuations and pressure changes during the freeze-drying process may cause some components to decompose or recombine, changing the composition of the aroma and affecting the stability of the final product.

(2) Effect of temperature on the chemical structure of fragrance oils

Effect of low temperature: Although low temperature helps to reduce the loss of volatile components, if the temperature during the freezing process is too low, it may cause some components in the fragrance oil to freeze excessively, thereby affecting its molecular structure. In particular, some components in essential oils and complex aroma substances may become difficult to dissolve during the freezing stage, thereby affecting the release of aroma.

Excessive sublimation temperature: If the sublimation temperature is too high, some heat-sensitive components in the fragrance oil may decompose or degrade. For example, natural components in some fragrances (such as floral or fruity scents) may decompose at higher temperatures and lose their original aroma characteristics.

(3) Effect of pressure on fragrance components

During the freeze-drying process, dissolved gases (such as oxygen, carbon dioxide, etc.) in the fragrance oil may be released as the pressure decreases, which poses certain challenges to the chemical stability of the fragrance oil. If the fragrance ingredients contain substances that easily react with oxygen, the low-pressure environment may accelerate the oxidation reaction, resulting in a decrease in the quality of the fragrance. Under low-pressure conditions, the viscosity and fluidity of the fragrance oil change, which may affect the overall stability and molecular structure of the fragrance oil and cause uneven fragrance distribution.

(4) Control of moisture content

During the freeze-drying process, moisture removal is achieved through sublimation, which is crucial for fragrance products. Residual moisture may cause changes in the fragrance oil, resulting in a decrease in the solubility and durability of the fragrance. Therefore, during the freeze-drying process, the moisture content must be strictly controlled to maintain the chemical stability of the fragrance.

(5) Storage stability of fragrance products

After the freeze-drying process, the fragrance oil can usually maintain its stability for a longer time in a moisture-free environment. After freeze-drying, the fragrance oil can maintain its chemical structure and fragrance characteristics for a long time and is not easy to deteriorate. However, the freeze-dried fragrance oil still needs to be kept at a suitable temperature and environment, otherwise the fragrance may change due to air, light or temperature changes.

Personalized and Full-Process Customization Services

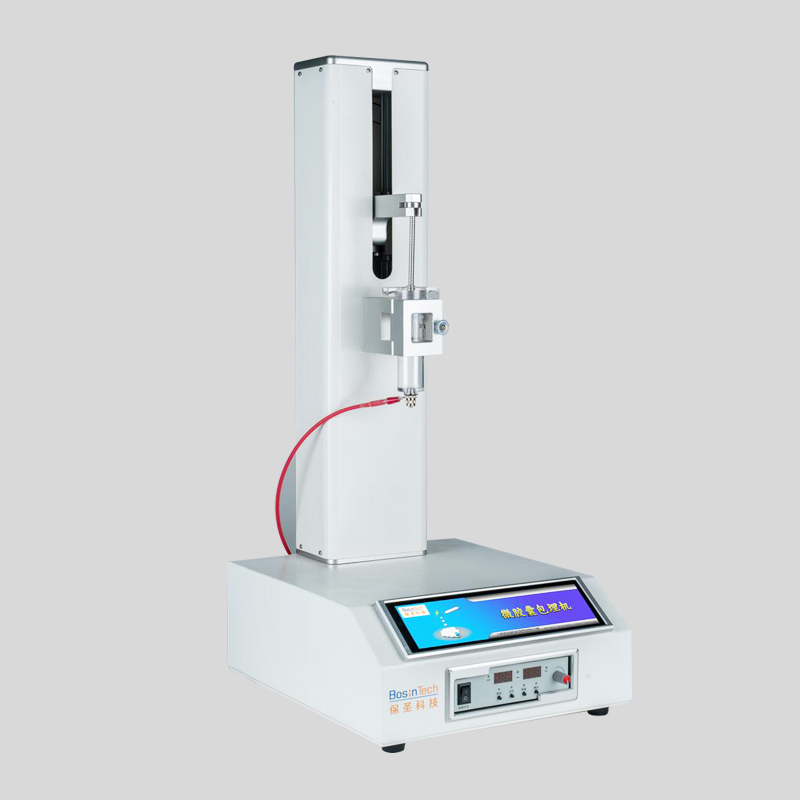

Personalized Customization: Based on individual customer needs, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. offers comprehensive customization services, ensuring that equipment and production processes fully meet specific requirements. This includes customizing freeze-drying equipment for fragrance products to accommodate varying product types, operating requirements, equipment size, and structure. Whether it's a small household unit or a large-scale industrial production line, the company offers tailored solutions tailored to each customer's specific needs.

Project Customization: The company not only customizes solutions based on customer product requirements but also provides support throughout each project phase, from R&D to production. For freeze-drying fragrance products or other specialized materials, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. can provide detailed equipment design and configuration based on product characteristics and production requirements, ensuring that all equipment parameters are optimally aligned with the customer's production requirements.

Production Layout and Process Planning: In addition to customizing equipment, the company also offers complete production layout and process design. This means that when selecting equipment, customers receive not only the equipment design itself but also comprehensive support for optimizing factory layout, improving production efficiency, and conducting process testing based on actual production needs. These plans and drawings not only assist customers with equipment configuration but also help optimize overall production line performance.

Process Testing and Samples: Before equipment delivery, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. will provide process test samples based on actual customer needs to verify that the equipment meets project requirements. This testing helps customers better understand equipment performance, ensuring that the final equipment fully meets production needs and avoiding any subsequent non-compliance issues. Testing criteria include comprehensive consideration of multiple performance indicators, including low temperature, vacuum, and freeze-drying.

Full-Scale Adaptability from R&D to Production: Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s freeze-drying equipment for fragrance products can meet the needs of both laboratory-level research and large-scale industrial production. This comprehensive adaptability enables the company to provide tailored solutions for clients of varying sizes and industries, covering the entire process from small-batch R&D to large-scale industrial production. This ensures that the equipment can meet diverse needs, from product development to production, and from small-scale trials to fully automated production.

Through this comprehensive customization service, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. ensures that each client receives tailored equipment and optimized production solutions, maximizing production efficiency and product quality.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China