How Do Freeze-Drying Solutions Enhance the Efficacy of Skincare Products?

The potency and effectiveness of skincare products heavily depend on the stability of their bioactive ingredients. Freeze-Drying Solutions for Skincare Products provide a precise method to preserve sensitive compounds that are easily degraded by heat, light, or oxidation. Vitamins like C and E, peptides, collagen fragments, and botanical extracts maintain their chemical structure and activity throughout production and storage.

Preservation of Bioactive Components:

The low-temperature, vacuum-assisted freeze-drying process effectively protects sensitive and heat-labile bioactive molecules that are easily degraded during conventional drying or processing methods. Vitamins such as C and E, peptides, hyaluronic acid fragments, and botanical extracts retain their molecular structure and full biological activity. Antioxidants, polyphenols, and essential oils found in plant extracts remain stable, supporting skin protection against environmental stressors. Peptides and protein fragments preserve their functional integrity, contributing to improved skin elasticity, repair, and regeneration. By maintaining the potency of these delicate compounds, Freeze-Drying Solutions for Skincare Products ensure that the final formulations deliver the scientifically intended benefits for healthy, radiant skin.

Consistent Product Performance:

Freeze-drying guarantees that each batch of skincare products contains consistent concentrations of active ingredients, allowing brands to reliably deliver measurable results. Consumers can expect uniform efficacy in hydration, anti-aging, brightening, or barrier-reinforcing effects, whether using powders, serums, or masks. This reproducibility is especially important for multi-component formulations combining vitamins, peptides, and botanical extracts, as it ensures synergistic performance without loss of activity. Consistent dosage also strengthens consumer trust and supports compliance with cosmetic-grade quality standards. By eliminating variability caused by heat or moisture degradation, Freeze-Drying Solutions for Skincare Products maintain product integrity throughout storage, distribution, and usage.

Sensory and Aesthetic Retention:

Beyond preserving bioactivity, freeze-drying enhances the sensory and aesthetic qualities of skincare products. The process locks in natural colors, subtle aromas, and original textures of ingredients, producing visually appealing powders, masks, and serums that feel fresh and premium. Skincare powders remain fine and smooth, masks retain an even consistency, and serums dissolve or mix easily without clumping or separation. Consumers experience products that are both effective and indulgent, providing a luxurious application experience without the need for synthetic stabilizers or artificial additives. This sensory fidelity not only reinforces brand image but also aligns with the growing demand for clean-label, natural, and high-quality cosmetic solutions.

These advantages allow skincare brands to position their products as high-efficacy and science-backed, enhancing consumer trust while differentiating them from conventional formulations that may lose potency over time.

What Technical Advantages Make Freeze-Drying Ideal for Skincare Applications?

The technical sophistication behind Freeze-Drying Solutions for Skincare Products ensures that active ingredients, formulation integrity, and long-term stability are maintained across various product types and scales.

Gentle, Low-Temperature Drying:

Freeze-Drying Solutions for Skincare Products utilize a carefully controlled, low-temperature drying process that avoids the high-heat exposure common in conventional drying or thermal processing methods. This approach is essential for preserving the integrity of delicate vitamins, peptides, and botanical extracts. Water-soluble antioxidants, thermosensitive enzymes, and bioactive complexes remain chemically stable, preventing degradation that could compromise efficacy. By maintaining the functional properties of these sensitive ingredients, freeze-drying ensures that skincare products deliver the intended benefits such as antioxidant protection, collagen support, and enhanced skin repair mechanisms. This gentle approach allows for the formulation of premium, high-potency products that meet the expectations of health-conscious and luxury beauty consumers.

Flexible Product Formats:

The versatility of Freeze-Drying Solutions for Skincare Products allows manufacturers to produce a wide range of formats, including powders, face masks, serums, and concentrated bioactive extracts. Powders can be easily reconstituted on-demand for masks, lotions, or customized skincare blends, providing convenience for consumers. Face masks retain their structural stability during storage, ensuring even distribution of active ingredients upon application. Serums and concentrated extracts maintain high solubility and bioavailability, allowing for rapid absorption and maximum effectiveness on the skin. This flexibility empowers brands to innovate with product types and combinations, offering unique, high-value experiences that meet diverse consumer preferences.

Controlled and Scalable Process:

Advanced freeze-drying equipment provides precise control over key parameters such as vacuum, temperature, and drying duration. Freeze-Drying Solutions for Skincare Products ensure uniform moisture removal, consistent product purity, and repeatable quality across batches. The controlled environment prevents uneven drying or ingredient degradation, maintaining the stability of bioactive compounds. Scalability is also a key advantage: from laboratory R&D experiments to pilot runs and full-scale industrial production, the process retains the efficacy and sensory quality of ingredients. This capability enables brands to develop consistent, high-performance skincare lines while efficiently scaling operations to meet market demand.

Regulatory and Quality Compliance:

The method aligns seamlessly with cosmetic-grade and food-grade regulations, supporting ISO, GMP, and HACCP compliance. By minimizing the need for chemical stabilizers, artificial preservatives, or synthetic additives, Freeze-Drying Solutions for Skincare Products cater to the growing demand for clean-label, eco-conscious skincare. This regulatory alignment not only simplifies product approval and global distribution but also enhances brand credibility and consumer trust. Brands can confidently market high-efficacy, safe, and sustainable products that satisfy stringent international standards and increasingly sophisticated consumer expectations.

Maximizing Functional Performance and Consumer Satisfaction:

By leveraging these technical advantages, Freeze-Drying Solutions for Skincare Products empower brands to create innovative skincare lines that combine potent bioactive ingredients with appealing sensory qualities and long-term stability. Products maintain their effectiveness throughout their shelf life, providing consumers with predictable results in hydration, anti-aging, brightening, and overall skin health. At the same time, the flexibility in product format, regulatory compliance, and gentle processing methods ensures that brands can meet diverse market demands, differentiate themselves with premium offerings, and reinforce loyalty through consistent, high-quality performance.

By leveraging these technical advantages, brands can develop innovative skincare lines that maximize both functional performance and consumer satisfaction.

How Does Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd Support the Production of Freeze-Dried Skincare Products?

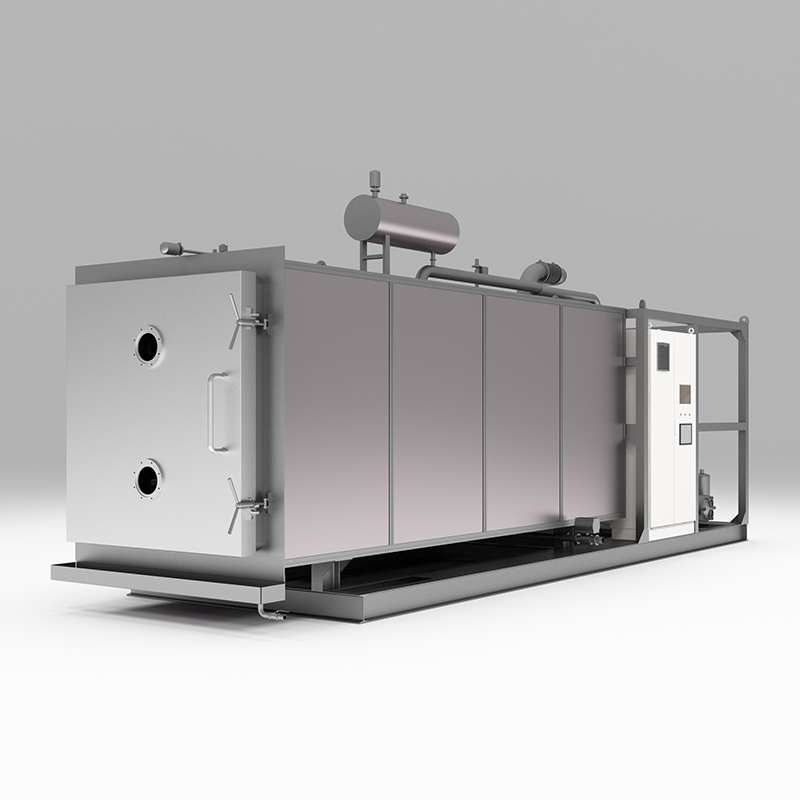

Sieno’s comprehensive freeze-drying solutions provide end-to-end technical support for producing high-quality Freeze-Drying Solutions for Skincare Products. Their equipment covers the entire process chain from experimental research to industrial-scale manufacturing offering energy efficiency, stability, and flexible customization.

Specialized equipment for skincare formulations: Machines such as low-temperature vacuum freeze-dryers, online moisture monitors, and nitrogen protection systems ensure that moisture-sensitive, oxygen-sensitive, and thermally fragile ingredients are fully preserved during production.

Energy-efficient and stable operation: Automation and precise environmental control reduce energy consumption while maintaining consistent drying conditions. This ensures batch-to-batch uniformity in nutrient retention, active ingredient stability, and product texture.

Customizable and scalable configurations: Equipment supports small-batch R&D trials, pilot runs, and full-scale industrial production. Brands can experiment with diverse ingredients, formulations, and product formats without risking loss of efficacy or sensory quality.

End-to-end process integration: Sieno provides comprehensive process support, including pretreatment, freeze-drying, and packaging. Intelligent monitoring systems optimize efficiency, minimize waste, and enhance the shelf-life and stability of skincare products.

Green manufacturing solutions: The focus on energy efficiency and process optimization reduces environmental impact, supporting sustainable production practices while delivering high-quality, reliable skincare products.

Through these capabilities, Sieno empowers skincare brands to produce visually appealing, potent, and stable products that meet global standards, satisfy consumer demands for clean-label and high-efficacy solutions, and maintain competitive differentiation in the rapidly evolving beauty industry.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China