What is the role of Freeze-Drying Equipment for Pet Nutritional Supplements?

In the production of pet nutritional supplements, Freeze-Drying Equipment for Pet Nutritional Supplements plays a vital role, mainly by maintaining the nutritional content, taste and active ingredients in the product through an efficient dehydration process. Freeze-drying technology is particularly suitable for processing heat-sensitive and high-value nutritional ingredients, avoiding the nutritional loss caused by traditional drying methods.

(1) Retaining active ingredients

Freeze-drying equipment removes moisture at low temperatures during the production process, avoiding the risk of high-temperature inactivation of active ingredients (such as probiotics, vitamins, enzymes, etc.). For example, probiotics and enzyme ingredients can retain their biological activity during the freeze-drying process, ensuring the effectiveness and stability of the final product. This makes Freeze-Drying Equipment for Pet Nutritional Supplements an ideal choice for producing high-quality pet supplements.

(2) Extending the shelf life

Freeze drying can effectively remove moisture, ensuring a low moisture content in pet nutritional supplements, thereby greatly reducing the growth of microorganisms and the occurrence of chemical reactions, and extending the shelf life of the product. This feature is particularly suitable for pet nutritional supplements that are stored and transported for a long time.

(3) Maintaining the shape and taste of the product

Unlike traditional drying methods, freeze drying can remove moisture while retaining the shape and taste of the raw materials. For pet nutritional supplements containing sensitive ingredients (such as plant extracts, natural taste, etc.), freeze drying technology can maximize the preservation of the natural taste and shape of these ingredients, making pet supplements more acceptable to pets.

(4) Improving production efficiency and consistency

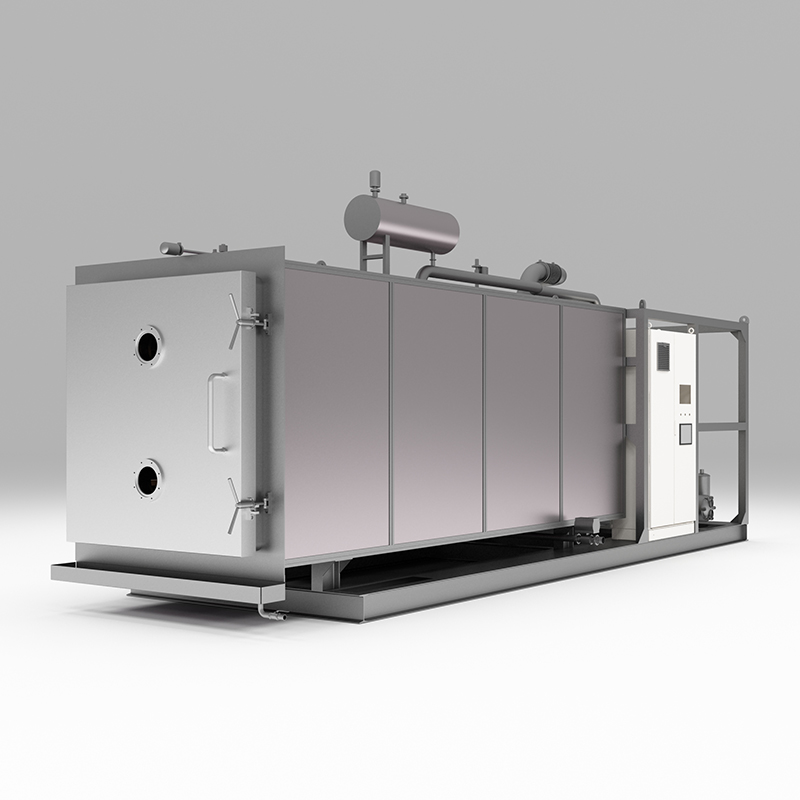

Modern freeze drying equipment has a highly automated control system that can accurately adjust the temperature, vacuum degree and time according to different production requirements to ensure the quality consistency of each batch of products. In large-scale production, Freeze-Drying Equipment for Pet Nutritional Supplements can improve production efficiency, reduce manual intervention, and ensure the efficiency and stability of the production process.

Effect of Freeze-Drying Equipment for Pet Nutritional Supplements on Nutrients

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd., with its years of experience in freeze-drying technology, especially in the food processing field, is able to effectively preserve the nutrients in pet nutritional supplements through its independently developed intelligent freeze-drying equipment. These equipment provide optimal protection for nutrients by precisely controlling temperature, pressure and vacuum, avoiding the damage that may be caused by traditional heat drying methods.

(1) Preservation of heat-sensitive ingredients

Freeze-drying technology is one of the core competencies of Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd., and has significant advantages in processing heat-sensitive nutrients (such as vitamins, probiotics and enzymes). By using its independently developed intelligent freeze-drying equipment, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. is able to remove moisture at low temperatures, thereby avoiding the degradation of vitamins and active ingredients that may be caused by heat treatment. This low-temperature sublimation process can maximize the preservation of important active ingredients in pet nutritional supplements, ensuring their effectiveness and stability.

(2) Reduce oxidation and nutrient loss

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd combines the world's leading freeze-drying technology resources and strategically collaborates with experts from Chinese universities and food science colleges to enable its equipment to achieve industry-leading levels in reducing oxidation and maintaining nutritional value. By optimizing the vacuum system and control system of the freeze-drying equipment, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd can effectively isolate the effects of oxygen on fatty acids, minerals and other sensitive ingredients, ensuring the stability and high bioavailability of these ingredients throughout the production process. This is crucial to ensuring the quality and effectiveness of pet nutritional supplements.

(3) Efficiently retain the biological activity of nutrients

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd's intelligent freeze-drying equipment is equipped with high-precision sensors and control systems that can monitor temperature and humidity changes in real time during the drying process, ensuring that the active ingredients in pet nutritional supplements are not lost during the freeze-drying process. For example, probiotics, enzymes, and high-protein ingredients can maintain their activity in a low-temperature, vacuum environment, avoiding the loss of biological activity that may occur with traditional drying methods.

(4) Extending shelf life and improving product stability

Thanks to the precise control of Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd's freeze-drying equipment, pet nutritional supplements can minimize bacterial growth, mold, and oxidation reactions while removing moisture. By controlling the drying process of each batch of products, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd helps customers achieve a long and stable product shelf life and ensure the long-term effectiveness of nutrients. This low moisture and low oxygen environment not only improves the stability of the product, but also allows the nutrients to maintain their effects and value for a longer period of time.

Through the unique advantages of freeze-drying equipment from Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd, Freeze-Drying Equipment for Pet Nutritional Supplements can process sensitive ingredients in pet nutritional supplements in a more efficient and precise manner, ensuring the quality and nutritional value of the final product.

How does Freeze-Drying Equipment for Pet Nutritional Supplements meet the needs of different types of pet nutritional supplements?

Pet nutritional supplements come in many types, including liquid, powder, granular, and compound types. The flexibility and adjustability of Freeze-Drying Equipment for Pet Nutritional Supplements enable it to optimize processing for different types of products, ensuring the quality and efficacy of various nutritional supplements.

(1) Freeze-drying of liquid pet nutritional supplements

Liquid pet nutritional supplements (such as liquid vitamins, liquid proteins, etc.) usually contain a high amount of water. Freeze-drying equipment needs to be able to efficiently remove moisture from liquids while ensuring that their active ingredients are not destroyed by excessive temperatures. In this case, Freeze-Drying Equipment for Pet Nutritional Supplements needs to be equipped with advanced freezing and sublimation control systems to handle temperature changes and pressure control when the liquid is converted into freeze-dried material to ensure the quality of the final product.

(2) Drying of powdered and granular pet nutritional supplements

Powdered and granular pet nutritional supplements (such as protein powder, mineral supplements, etc.) are relatively easy to freeze-dry, but their production process needs to ensure uniform drying. Freeze-Drying Equipment for Pet Nutritional Supplements uses a layered design that can provide a uniform freezing and sublimation process for each granule or powder, ensuring that all ingredients can remove moisture under the same conditions. The temperature, vacuum degree and drying time of the equipment can be precisely adjusted to avoid local over-drying or over-wetting, ensuring the stable quality of the final product.

(3) Supplements with high fat and oil content

For pet nutritional supplements rich in oil (such as fish oil, omega-3 fatty acid supplements, etc.), traditional drying methods are prone to fatty acid oxidation, affecting product quality. Freeze-drying can remove moisture without destroying the fatty acid structure through the low-temperature sublimation process, ensuring the stability of the oil components. Freeze-Drying Equipment for Pet Nutritional Supplements can ensure that these high-fat supplements are not thermally oxidized or deteriorated in quality during the production process by adjusting the drying temperature and sublimation rate.

(4) Drying of compound pet nutritional supplements

Complex pet nutritional supplements usually contain multiple ingredients (such as minerals, vitamins, enzymes and plant extracts, etc.). These ingredients have different properties, so freeze-drying equipment needs to flexibly adjust drying parameters according to the requirements of different ingredients. Freeze-Drying Equipment for Pet Nutritional Supplements is equipped with a highly intelligent control system that can automatically adjust the temperature, vacuum degree and time according to different production needs to ensure that each ingredient is fully protected.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China