With the growing global demand for high-performance batteries and energy storage systems, innovative materials and manufacturing techniques have emerged. Among these, freeze-drying technology has attracted increasing attention in the field of battery technology, particularly for its ability to improve battery performance, extend service life, and enable large-scale production. As an industry leader in freeze-drying technology research, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd, with years of technological expertise and innovative solutions, is committed to providing highly efficient freeze-drying solutions for batteries and energy materials.

Freeze-Drying of Slurries, Precursors, and Electrode Materials

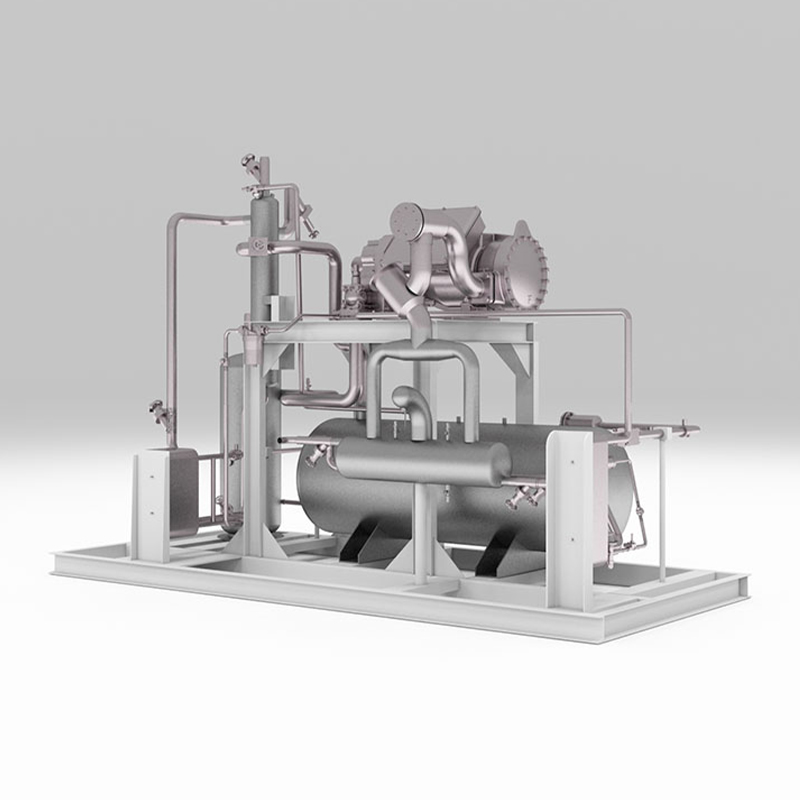

The core principle of freeze-drying technology is to remove solvents or water from materials by transitioning them from solid to gas in a low-temperature and low-pressure environment, avoiding the high temperatures, chemical changes, or structural damage that may occur with traditional drying methods. In battery production, the preparation of electrode materials is critical, especially the handling of slurries, precursors, and electrode materials.

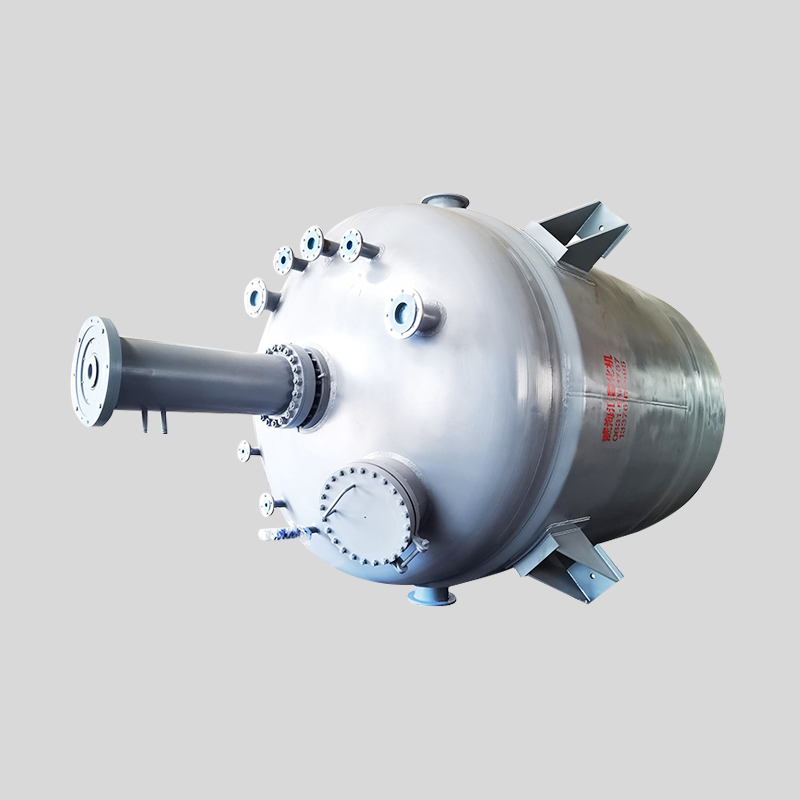

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd provides freeze-drying solutions that effectively address the challenges faced by traditional drying methods. Specifically, in battery manufacturing, electrode materials are often made by mixing active materials (such as lithium iron phosphate, nickel-cobalt-manganese) with binders and solvents to create slurries. Freeze-drying plays a key role in this process by preventing the degradation that can occur with high-temperature drying, allowing solvents to be removed while preserving the fine structures and active surfaces of the electrode materials, which ultimately enhances battery performance.

Furthermore, freeze-drying can be applied to the treatment of battery precursors. These precursors are essential chemical materials used to manufacture batteries, and freeze-drying helps maintain their chemical stability by preventing degradation due to solvent evaporation or chemical reactions during traditional drying processes. This not only improves the overall performance of the battery but also ensures precision in production.

Controlled Sublimation Preserves Fine Structures and Active Surfaces

One of the unique advantages of freeze-drying is its ability to precisely control the sublimation process, which helps preserve the fine structures and active surfaces of materials. In battery manufacturing, the active surface area of electrode materials is crucial for electrochemical performance. Traditional drying methods may cause damage to the microstructures of electrode materials due to excessive heat or rapid solvent evaporation, which ultimately affects conductivity and cycling stability.

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd’s freeze-drying solutions ensure the maximum preservation of the electrode materials’ fine structures and active surfaces by precisely controlling the temperature and pressure during the sublimation process. In a low-temperature, low-pressure environment, solvents are gradually removed, preventing thermal degradation or unwanted chemical reactions. This approach helps protect the electrode materials’ surface integrity, improving ion and electron conductivity, which leads to higher energy density and improved charge/discharge efficiency.

Moreover, freeze-drying also contributes to extending the cycle life of batteries. With the materials’ structures well-preserved, batteries maintain lower internal resistance over multiple charge and discharge cycles, which reduces energy loss and enhances longevity. This preservation of fine structures and active surfaces is essential for next-generation energy storage solutions and makes freeze-drying technology a crucial technique in battery development.

Uniform Drying Reduces Defects and Enhances Reproducibility

Uniform drying is a critical factor in battery manufacturing. Traditional drying methods, such as heat-based or convection drying, often lead to uneven drying rates and localized hot spots, which can result in defects such as cracking, warping, or uneven coating of electrode materials. These defects can negatively affect the mechanical strength and electrochemical properties of the batteries.

In contrast, freeze-drying provides a more uniform drying process. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd’s freeze-drying solutions offer a precisely controlled sublimation process, ensuring the uniform removal of solvents and water across the entire material. This consistent drying minimizes thermal damage and internal stress buildup, resulting in higher-quality materials with improved performance and reliability.

The uniformity of freeze-drying also contributes to greater consistency in large-scale production. In battery manufacturing, it is crucial to ensure that each batch of materials meets the same high-quality standards. Freeze-drying technology, through precise control of the drying environment, ensures that the quality of materials remains consistent from laboratory-scale development to full-scale production. This helps manufacturers reduce production risks and improve overall production efficiency, making freeze-drying an ideal solution for large-scale battery manufacturing.

The freeze-drying solutions offered by Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd not only help manufacturers improve material quality but also provide significant customer value. In battery and energy materials production, freeze-drying technology enhances electrochemical performance, extends cycle life, and offers scalable solutions for large-scale production.

Improved Electrochemical Performance and Cycle Life

By using freeze-drying technology to process battery materials, it is possible to significantly improve the electrochemical performance of the battery. Freeze-drying helps preserve the microstructures and active surfaces of electrode materials, optimizing the charge/discharge efficiency and energy density of the battery. In industries like electric vehicles (EVs), renewable energy storage, and consumer electronics, the electrochemical performance of batteries directly impacts product performance and market competitiveness.

Furthermore, freeze-drying technology extends the cycle life of batteries. Since the structures of the materials are better preserved, the batteries maintain lower internal resistance over many charge and discharge cycles, reducing energy loss and extending their operational life. Therefore, the overall performance and economic efficiency of the battery are greatly improved.

Consistent Quality for Large-Scale Energy Applications

As the demand for large-scale energy storage solutions grows, ensuring consistent quality across mass-produced battery cells becomes a major challenge. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd’s Freeze-Drying Solutions for Batteries and Energy Materials provide precise control over the drying process, ensuring that each batch of materials undergoes the same high-quality preparation. This uniformity is critical for applications where reliability and safety are paramount, such as grid storage and electric vehicles.

In large-scale energy storage projects, particularly for grid storage and electric vehicles, battery consistency and stability are essential. Freeze-drying technology not only enhances the electrochemical performance of batteries but also provides reliable quality assurance for large-scale energy applications.

Reduced Production Risk and Faster Commercialization

Freeze-drying technology also reduces production risks and accelerates product commercialization. By precisely controlling every aspect of the drying process, freeze-drying helps mitigate production bottlenecks caused by material issues. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd provides scalable freeze-drying solutions that enable manufacturers to transition from R&D to large-scale production smoothly and efficiently.

By reducing production risks and speeding up product development cycles, freeze-drying technology helps companies stay competitive in the fast-evolving battery and energy materials market. It enables quicker market response times and faster product launches, which are critical for staying ahead in the competitive energy storage industry.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China