One of the key advantages of using freeze-drying technology is the superior preservation of nutrients, especially when compared to other drying methods. In traditional drying processes, such as heat-based drying or sun-drying, a significant portion of the nutritional content is lost due to the exposure to high temperatures or prolonged drying times. Freeze-drying, on the other hand, operates at low temperatures, which helps in retaining vital vitamins, minerals, and antioxidants that are essential for maintaining the nutritional integrity of agricultural products. By preserving these nutrients, freeze-dried products offer more health benefits, making them particularly appealing in the growing health-conscious food market. For instance, fruits such as strawberries, apples, and blueberries, when freeze-dried, retain their original vitamin content, including vitamin C, which is often diminished in other drying processes. Vegetables like spinach and kale also maintain their high levels of iron and other minerals, ensuring that consumers benefit from the full nutritional profile of these products, even after long-term storage. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. has placed a strong emphasis on developing equipment that optimizes the freeze-drying process to ensure that we can deliver agricultural products to the market with minimal nutritional degradation.

The flavor profile of agricultural products is one of the most critical attributes for consumers. Traditional drying methods, especially heat drying, can cause changes in the flavor and aroma of the product. These changes are often due to the degradation of volatile compounds that contribute to the natural taste and smell of the product. Freeze-drying, however, is a gentle process that allows the product to retain its original flavors and aromas because the moisture is removed without causing the degradation of these essential compounds. When we consider products like herbs, spices, and fruits, the flavor retention becomes even more important for consumers who rely on these products for their culinary use. For example, freeze-dried basil, oregano, or thyme will retain much of their original fragrance and flavor profile, unlike heat-dried alternatives, which can lose much of their aromatic essence. Similarly, freeze-dried fruits like mango and peach will taste as fresh as their non-dried counterparts, providing consumers with a high-quality, flavorful product that is more appealing in the marketplace. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. has developed specialized equipment that ensures the preservation of these delicate flavor compounds by controlling the temperature and pressure throughout the freeze-drying cycle.

Freeze-drying is widely known for its ability to extend the shelf life of agricultural products without the need for refrigeration or the addition of preservatives. This is a direct result of the removal of moisture from the product, which is the primary factor that facilitates the growth of microorganisms that lead to spoilage. By removing up to 98% of the moisture content, freeze-dried products are naturally preserved, significantly extending their shelf life compared to fresh or conventionally dried products. For agricultural producers, this benefit translates into reduced waste and improved product turnover. Products like freeze-dried fruits, vegetables, and even meats can be stored for months or even years without the need for refrigeration, making them more convenient for both suppliers and consumers. This extended shelf life is especially beneficial for shipping and exporting agricultural products, as it reduces the risk of spoilage during transportation. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. focuses on developing equipment that helps us achieve these extended shelf lives while ensuring that the product retains its original appearance, taste, and nutritional value.

Another notable benefit of freeze-dried agricultural products is their lightweight nature. The removal of moisture reduces the product's weight by a significant margin, making it much easier and more cost-effective to transport. This is particularly valuable for companies involved in the international trade of agricultural goods. For example, freeze-dried fruits and vegetables are ideal for the export market because they can be shipped at a fraction of the weight of their fresh counterparts, leading to lower transportation costs and greater efficiency in logistics. The lightweight nature of freeze-dried products makes them more attractive to consumers, particularly in the context of outdoor activities such as camping, hiking, and emergency preparedness. Freeze-dried meals, for instance, have become a popular choice for those seeking easy-to-prepare, shelf-stable food options. These products are not only light but also compact, taking up significantly less storage space than fresh or dehydrated products. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. provides equipment that optimizes the drying process, ensuring that the products are not only preserved for a long time but are also conveniently packaged for ease of transport and storage.

Freeze-drying helps to preserve the shape, color, and texture of agricultural products. This is particularly important for products like fruits, vegetables, and flowers, where the visual appeal plays a major role in consumer acceptance. Traditional drying methods, especially heat-based drying, can cause significant changes to the appearance of the product, often leading to color degradation, shrinkage, and loss of structural integrity. Freeze-dried products, on the other hand, maintain their original shape and color because the process removes moisture without the application of heat. For agricultural producers, this benefit is especially valuable in markets where presentation is crucial. For example, freeze-dried strawberries, when rehydrated, look and taste like fresh strawberries, with their original color and size intact. This makes freeze-dried products an ideal choice for use in food products like cereals, snacks, and baking ingredients. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. has invested in the development of freeze-drying equipment that ensures superior product quality by maintaining the integrity of the agricultural product throughout the drying process. Our technology focuses on precise temperature and pressure control to preserve the physical attributes of agricultural goods.

Environmental sustainability is a growing concern in the agricultural industry, and freeze-drying presents a more environmentally friendly alternative to other drying methods. Compared to traditional methods that require large amounts of energy for heating or sun-drying, freeze-drying uses significantly less energy and can be powered by renewable sources, making it a more eco-friendly solution. The reduced need for refrigeration during transportation and storage further minimizes the environmental impact of freeze-dried agricultural products. Freeze-drying helps to reduce food waste by extending the shelf life of agricultural products, making it easier for consumers and producers to store surplus goods without the fear of spoilage. This has direct implications for reducing food waste on a global scale, as agricultural products can be preserved for longer periods without losing their nutritional value or flavor. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. is committed to advancing sustainable food processing technologies through the development of energy-efficient and environmentally responsible freeze-drying systems. Our focus on reducing energy consumption and waste generation ensures that we contribute to the broader goals of sustainability in the agricultural sector.

Nitrogen-Filled Aluminum Foil Packaging Machine for Agricultural Products

Nitrogen-Filled Aluminum Foil Packaging Machine for Agricultural Products

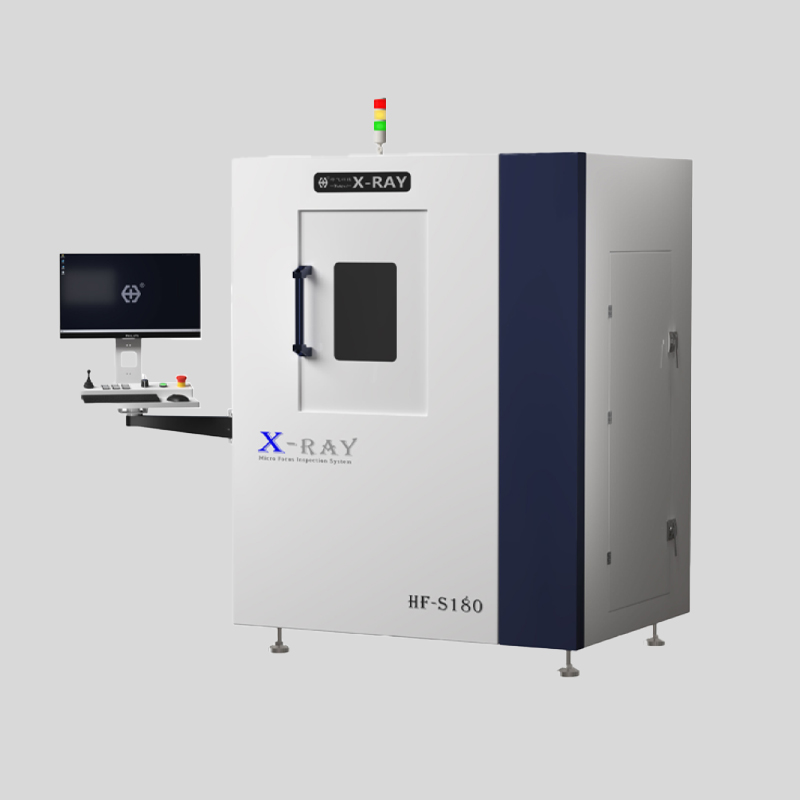

Metal Detection + X-Ray Machine for Agricultural Products

Metal Detection + X-Ray Machine for Agricultural Products

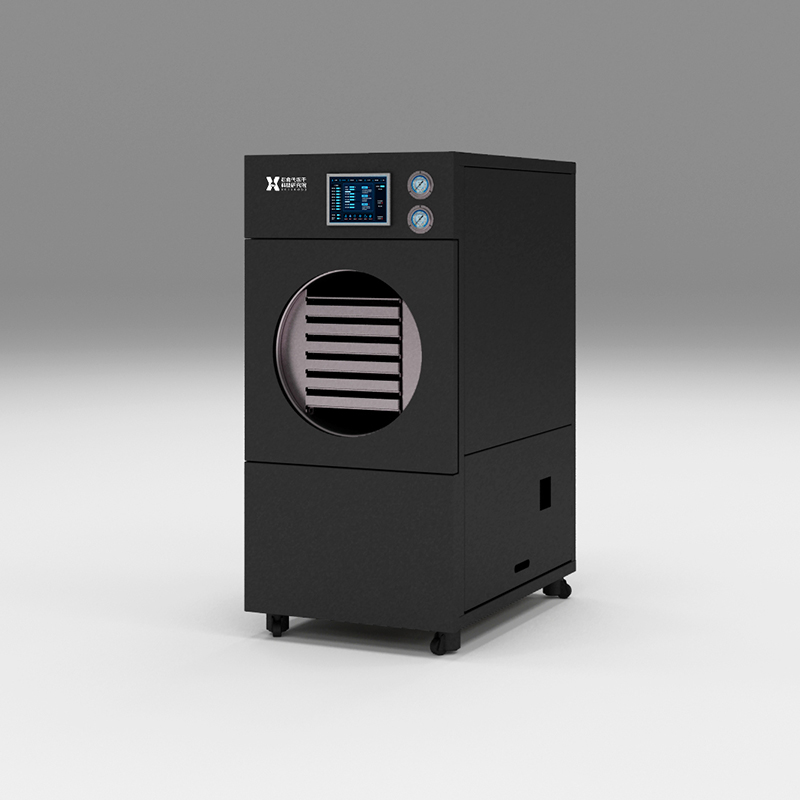

Vacuum Freeze Dryer for Agricultural Products

Vacuum Freeze Dryer for Agricultural Products

Multifunctional Dicer for Agricultural Products

Multifunctional Dicer for Agricultural Products

Optical Sorter for Agricultural Products

Optical Sorter for Agricultural Products

Bubble Cleaner for Agricultural Products

Bubble Cleaner for Agricultural Products