What Technical Advantages Make Freeze-Drying Equipment Essential for Cosmetics?

The stability, efficacy, and sensory appeal of cosmetic ingredients increasingly depend on advanced processing techniques. Many vitamins, peptides, enzymes, and plant bioactives are highly sensitive to heat, moisture, or oxidation, and conventional drying methods often compromise their functionality. Freeze-drying equipment addresses these challenges by offering precise, low-temperature, vacuum-assisted drying that preserves molecular integrity, ensures reproducible quality, and allows for versatile product formats. This technological approach enables cosmetic manufacturers to create high-performance, clean-label products that meet regulatory standards while satisfying consumer expectations for efficacy and aesthetic appeal.

Gentle low-temperature drying:

Freeze-drying removes water under vacuum at temperatures far below boiling, preventing heat-sensitive vitamins, enzymes, peptides, and plant bioactives from denaturation or oxidation. This gentle approach is critical for ingredients like thermosensitive antioxidants, collagen peptides, or volatile botanical extracts, which can lose potency under conventional drying. Maintaining molecular integrity ensures that cosmetic ingredients deliver consistent functional benefits in hydration, anti-aging, brightening, and skin barrier-supporting products.

Controlled vacuum profiles and uniform moisture removal:

Modern freeze-drying systems allow precise control of vacuum and sublimation rates, avoiding structural collapse of powders, granules, or extracts. Uniform moisture removal enhances solubility, stability, and reconstitution performance. Ingredients maintain their natural shape, color, and aroma, which is crucial for high-end cosmetics where sensory quality and appearance influence consumer perception. This precision also reduces batch variability, ensuring reproducibility across multiple production runs.

Flexible product formats:

Freeze-drying equipment supports diverse cosmetic formats including powders, serums, masks, functional granules, and concentrated extracts. Powders can be reconstituted on demand, serums retain solubility and bioavailability, and masks remain structurally stable over time. This versatility allows cosmetic manufacturers to develop multi-functional products, integrate complex bioactive blends, and meet consumer expectations for innovative formulations without compromising ingredient quality.

Scalable and compliant process:

Equipment scalability ensures consistent performance from small-lab experiments to full-scale industrial production. Precise control over temperature, vacuum, and drying cycles aligns with cosmetic-grade standards, ISO, GMP, and HACCP requirements. Manufacturers can reliably reproduce ingredient quality at larger volumes, accelerating product development while meeting regulatory expectations globally.

How Do Cosmetic Brands Benefit from Freeze-Drying Equipment for Ingredients?

Cosmetic brands increasingly seek methods to deliver products that are both effective and appealing while meeting modern consumer demands for clean-label, high-performance formulations. Freeze-drying equipment provides a reliable solution by preserving sensitive bioactives, maintaining structural integrity, and ensuring consistent quality across batches. This technology supports innovation, enhances ingredient stability, extends shelf life, and improves operational efficiency, enabling brands to create premium cosmetic lines that resonate with consumers and perform as promised.

Enhanced ingredient stability and performance:

By preserving the structural and biochemical integrity of sensitive ingredients, freeze-drying ensures consistent efficacy across batches. Vitamins, peptides, enzymes, and botanical extracts retain their bioactivity, allowing brands to develop products that consistently deliver hydration, elasticity, anti-aging, or brightening effects. Consumers can trust that each product will perform as promised, reinforcing brand credibility and supporting long-term loyalty.

Extended shelf life without chemical additives:

Eliminating moisture and controlling oxygen exposure during freeze-drying naturally inhibits microbial growth and oxidation. This significantly extends ingredient shelf life without relying on chemical stabilizers or preservatives, supporting clean-label claims. Cosmetic brands can store and transport raw materials safely, reduce waste, and offer long-lasting products to global markets without compromising safety, quality, or bioactive potency.

Innovation and product differentiation:

Freeze-drying technology enables the creation of novel formulations, including multi-component powders, masks, and concentrated serums that retain full activity of bioactive ingredients. Brands can explore unique textures, sensory experiences, and functional benefits, differentiating themselves in premium, natural, and functional cosmetic categories. Flexibility in ingredient integration allows the launch of innovative product lines tailored to niche markets or evolving consumer preferences.

Operational efficiency and reproducibility:

Automated freeze-drying systems reduce the risk of batch failures, enhance process control, and optimize energy use. Manufacturers can reliably scale up production without compromising quality, supporting rapid commercialization of new formulations. This efficiency reduces costs, increases throughput, and ensures that cosmetic brands can meet increasing consumer demand while maintaining high standards of consistency and compliance.

Maximizing Brand Value through Advanced Freeze-Drying:

By leveraging freeze-drying equipment, cosmetic brands can maintain the potency, efficacy, and sensory appeal of ingredients while enabling operational flexibility and innovation. The technology strengthens product reliability, supports clean-label positioning, and allows differentiation in a crowded market. Ultimately, freeze-drying empowers brands to deliver high-quality, stable, and compelling cosmetic products that meet the expectations of discerning consumers worldwide.

What Makes Sieno’s Freeze-Drying Equipment for Cosmetic Ingredients Stand Out?

In today’s competitive cosmetics market, brands require Freeze-Drying Equipment for Cosmetic Ingredients that not only preserves ingredient efficacy but also ensures reproducible quality, operational efficiency, and scalability. Sieno’s Freeze-Drying Equipment for Cosmetic Ingredients is engineered to meet these demands, providing specialized technology that protects delicate bioactives, maintains structural and biochemical integrity, and supports innovative product development. By combining advanced monitoring, flexible design, and eco-efficient operation, Sieno enables manufacturers to deliver premium, high-performance cosmetic ingredients that meet both regulatory standards and consumer expectations.

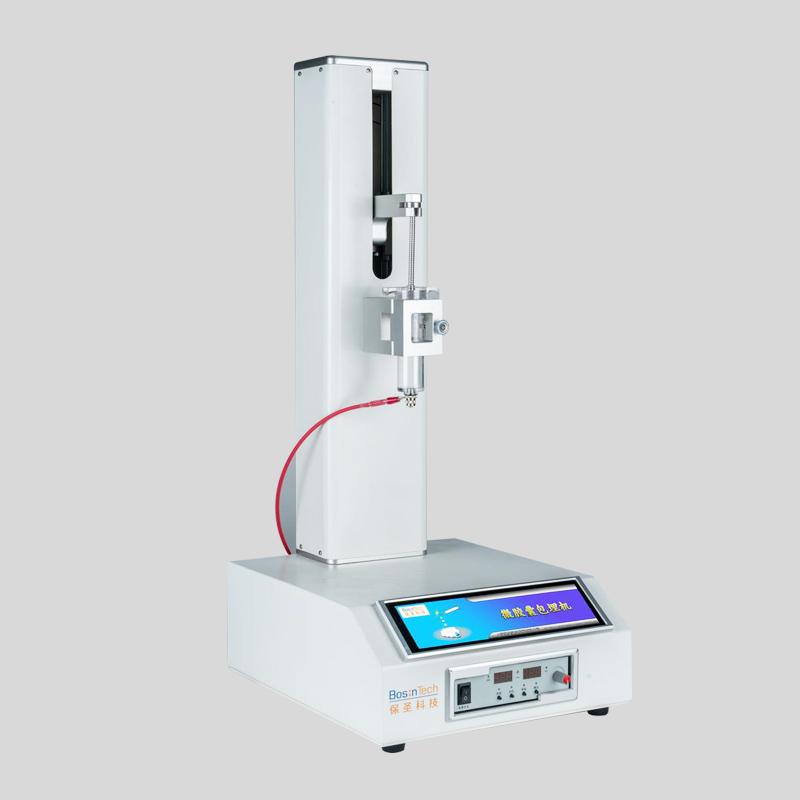

Specialized low-temperature vacuum freeze-dryers:

Sieno’s Freeze-Drying Equipment for Cosmetic Ingredients is designed specifically to protect delicate bioactives such as peptides, enzymes, probiotics, and botanical extracts. Sublimation rates and temperature profiles are finely tuned to maintain molecular integrity, ensuring reproducible bioactivity and functional efficacy. Multi-component formulations remain stable, enabling brands to offer complex, high-performance cosmetic products without compromise. The precision of these freeze-dryers minimizes ingredient loss and supports consistent performance across batches, a critical factor in premium cosmetic manufacturing.

Real-time monitoring and controlled atmospheres:

Advanced sensors integrated into Sieno’s Freeze-Drying Equipment for Cosmetic Ingredients continuously track residual moisture and oxygen levels throughout the process. This ensures stability for oxidation-prone or moisture-sensitive ingredients. Integration of nitrogen flushing or inert gas systems protects compounds during drying and packaging, reducing oxidative degradation, extending shelf life, and eliminating reliance on chemical stabilizers. Controlled environments also enable consistent quality across batches, supporting regulatory compliance and reinforcing consumer trust in high-end cosmetic products.

Flexible and modular design:

The modular design of Sieno’s Freeze-Drying Equipment for Cosmetic Ingredients accommodates various batch sizes, ingredient types, and product formats. From small research batches to industrial production, powders, serums, masks, and granules can all be processed under optimized conditions. This flexibility allows customization of freeze-drying cycles, ingredient combinations, and product specifications, supporting innovation and diversification of cosmetic portfolios. Manufacturers can experiment with new formulations, integrate complex bioactive blends, and quickly adapt to changing market demands without compromising quality.

Energy-efficient, scalable, and eco-friendly operation:

Sieno’s Freeze-Drying Equipment for Cosmetic Ingredients features energy-efficient designs that minimize operational costs while maintaining precise control over vacuum, temperature, and sublimation. Scalable systems ensure reproducibility across R&D, pilot, and full-scale manufacturing. Integrated pretreatment, freeze-drying, and packaging modules, combined with intelligent process control, optimize efficiency, reduce waste, and support green manufacturing practices. Brands benefit from cost-effective, high-quality production that meets global standards, reinforces sustainability initiatives, and satisfies consumer expectations for premium cosmetic ingredients.

Delivering consistent quality and innovation:

By leveraging specialized Freeze-Drying Equipment for Cosmetic Ingredients, precise monitoring, modular flexibility, and eco-efficient operation, Sieno empowers cosmetic manufacturers to produce ingredients that maintain potency, stability, and visual appeal. This comprehensive approach allows brands to innovate confidently, scale efficiently, and consistently deliver products that meet the highest standards in efficacy, safety, and consumer satisfaction. Sieno’s solutions not only enhance operational performance but also elevate the overall value and competitiveness of cosmetic portfolios in the global market.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China