What is the energy consumption of freeze-drying equipment for instant meals and can it be operated fully automatically?

Energy Requirements of Freeze-Drying Equipment for Instant Meals

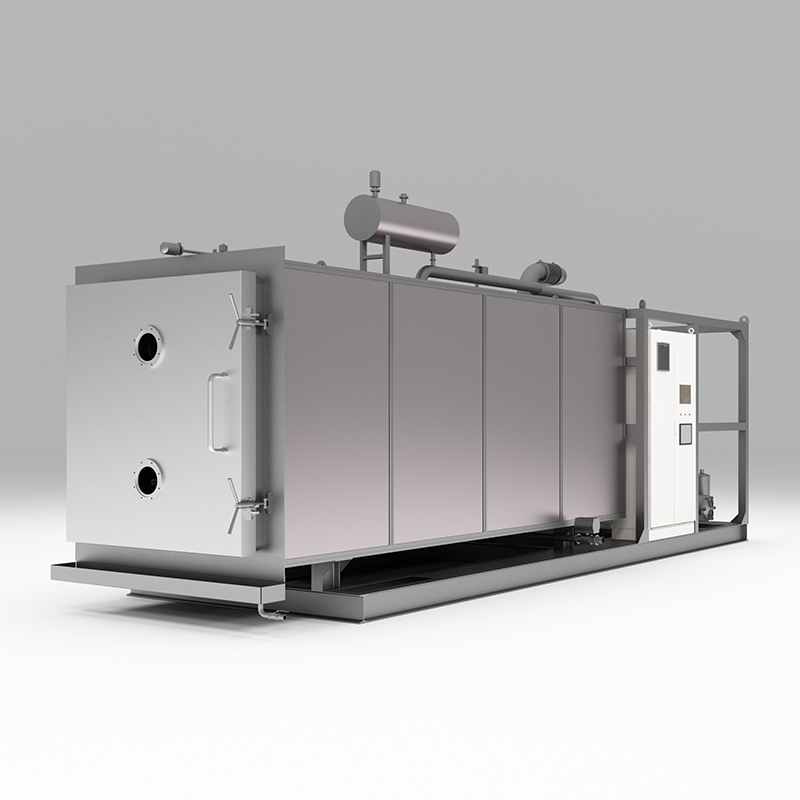

Freeze-drying equipment for instant meals consumes energy across multiple stages, including freezing, vacuum pumping, heating for sublimation, and condensation. The freezing stage requires significant electricity to bring the product temperature well below freezing, usually between -30°C and -50°C. This is followed by vacuum generation, where pumps must operate continuously to maintain a low-pressure environment, often below 100 mTorr. The sublimation stage then applies controlled heat to transform ice directly into vapor. Each of these processes contributes to the total energy load, which can vary depending on equipment size, batch volume, and cycle duration. Unlike conventional dehydration, freeze-drying is more energy-intensive because it removes moisture under vacuum and at low temperatures, requiring advanced thermal and pressure control systems.

Breakdown of Energy Consumption Across Processing Stages

The total energy consumption of freeze-drying equipment can be divided into different categories of power demand. Freezing typically represents 25–30% of the overall energy requirement. Vacuum pumping systems may account for 20–25%, depending on the efficiency of the pump design. The largest contributor is the sublimation heating stage, often requiring 40–50% of the total energy, since continuous heat must be supplied to maintain sublimation without melting the product. The condensation stage requires additional cooling energy to trap vaporized water, typically 10–15% of the load. This breakdown illustrates that energy efficiency improvements can be achieved at multiple points in the process.

| Process Stage | Energy Share (%) | Description |

|---|---|---|

| Freezing | 25–30% | Cooling food to sub-zero temperatures |

| Vacuum Pumping | 20–25% | Maintaining low pressure for sublimation |

| Sublimation Heating | 40–50% | Providing energy for ice-to-vapor transition |

| Condensation | 10–15% | Capturing and removing vaporized moisture |

Comparisons with Alternative Drying Methods

When compared with hot air drying or spray drying, freeze-drying equipment for instant meals typically consumes more energy per kilogram of finished product. Hot air drying involves direct application of heat and has lower power requirements but compromises nutrient and sensory qualities. Spray drying, though more energy-efficient for liquids and powders, is not suitable for structured meals that require preservation of texture and shape. Freeze-drying therefore occupies a unique space where energy intensity is traded off for higher product quality, longer shelf life, and enhanced rehydration performance. These benefits justify higher energy inputs in many cases, especially in premium instant meal markets.

Influence of Batch Size and Equipment Scale

The energy consumption per unit of product depends heavily on equipment scale and batch size. Large industrial freeze-drying equipment achieves better energy efficiency due to economies of scale, with shared refrigeration and vacuum systems supporting larger volumes. Small laboratory-scale freeze dryers consume more energy per kilogram because of inefficiencies in scaling and the higher relative energy demand of support systems. For instant meals, which are often produced in large volumes, industrial-scale systems are more practical and cost-effective despite higher absolute energy consumption.

Cycle Duration and Its Effect on Energy Use

Energy consumption is also affected by cycle duration. A typical freeze-drying cycle for instant meals may last 20–36 hours, depending on product thickness, composition, and desired moisture content. Longer cycles mean prolonged operation of compressors, pumps, and heaters, which increases energy consumption. Optimization of cycle parameters such as shelf temperature, vacuum level, and product loading can reduce overall time without compromising quality. Research and development in this area aim to shorten cycles and improve energy efficiency through real-time monitoring and predictive control algorithms.

Role of Automation in Freeze-Drying Equipment

Modern freeze-drying equipment for instant meals increasingly incorporates automation to ensure consistency and reduce manual intervention. Automation systems regulate freezing rates, control vacuum levels, adjust shelf temperatures, and monitor sublimation progress in real-time. Fully automated systems can run entire cycles with minimal operator input, only requiring supervision for loading and unloading. This reduces labor costs and minimizes risks of human error in critical processes. By automating controls, manufacturers can achieve better repeatability across batches, which is essential for instant meal production where standardization is key.

Automated Control of Vacuum and Temperature

One of the most energy-intensive aspects of freeze-drying is maintaining vacuum and temperature levels. Automated systems use sensors and feedback mechanisms to regulate pumps and heaters precisely. For example, pressure rise testing can be automated to detect the end point of primary drying, preventing unnecessary energy use from prolonged operation. Automated modulation of shelf temperatures also ensures efficient sublimation without overheating, which not only improves energy efficiency but also preserves product quality. Such automation enhances the operational flexibility of freeze-drying systems while reducing wasted energy.

Integration with Monitoring and Data Systems

Advanced freeze-drying equipment for instant meals often integrates with data logging and monitoring systems that track energy consumption, cycle progression, and equipment status. This allows operators to analyze energy use patterns and optimize settings for future runs. Predictive maintenance systems also rely on data integration to anticipate pump wear or compressor issues, reducing downtime and maintaining consistent energy performance. Automation combined with monitoring creates a closed-loop system that continually improves efficiency and reliability.

Energy Recovery and Efficiency Enhancements

Some modern freeze-drying systems incorporate energy recovery mechanisms, such as reusing waste heat from compressors or optimizing condenser cooling with heat exchangers. These measures reduce net energy consumption. For example, captured heat from refrigeration cycles can be redirected to assist sublimation heating, reducing electrical load. Similarly, energy-efficient vacuum pumps and variable frequency drives allow for better control of power consumption during different stages of drying. These enhancements contribute to lowering operational costs while maintaining effective freeze-drying of instant meals.

Cost Implications of Energy Consumption

Energy consumption directly impacts the cost of producing freeze-dried instant meals. While the energy per kilogram is higher than conventional drying methods, the overall value proposition includes improved shelf life, product stability, and rehydration quality. These advantages justify higher energy inputs for premium meal markets. However, energy costs can represent a significant percentage of total operational expenses. Manufacturers often conduct cost-benefit analyses comparing freeze-drying with alternative preservation methods. Energy-efficient equipment and automation can mitigate operational costs while ensuring quality standards are met.

Comparison of Manual and Automated Operation

Fully automated freeze-drying systems have advantages over semi-manual systems in terms of labor savings and operational consistency. Manual operation requires constant monitoring, with operators adjusting vacuum, shelf temperature, and condenser status based on readings. This increases labor intensity and the possibility of errors, leading to inefficient energy use. Automated systems, on the other hand, optimize cycle progression dynamically. The table below highlights the differences between manual and automated operation in freeze-drying equipment for instant meals.

| Aspect | Manual Operation | Automated Operation |

|---|---|---|

| Monitoring | Operator-dependent, constant supervision required | Automated sensors and control systems |

| Energy Efficiency | Varies, risk of overuse | Optimized by real-time adjustments |

| Consistency | Batch-to-batch variability | Stable and repeatable outcomes |

| Labor Costs | High, multiple operators required | Low, minimal supervision |

| Error Risk | Higher due to human intervention | Lower due to automated protocols |

Scalability and Industrial Application

For industrial-scale instant meal production, fully automated freeze-drying equipment is more practical. It enables simultaneous handling of large batches and ensures consistency across thousands of meal packs. Energy consumption per kilogram decreases with scale, even though absolute energy requirements increase. Automation further supports scalability by enabling continuous monitoring and adjustments, making it feasible to operate equipment for extended cycles without manual oversight. This combination of scalability and automation is essential for meeting the growing global demand for instant meals.

Impact on Product Quality

Energy consumption and automation both influence the final product quality in freeze-dried instant meals. Overuse of energy in poorly optimized systems can cause partial melting, nutrient loss, or uneven drying. Automated control helps prevent these issues by carefully regulating energy input. Consistent vacuum levels and precise heating ensure that moisture is removed evenly, maintaining the texture and flavor of instant meals. This makes automation not only an efficiency advantage but also a product quality assurance measure.

Environmental Considerations

Energy-intensive processes like freeze-drying also raise environmental concerns, particularly in terms of carbon footprint. Manufacturers of instant meal freeze-drying equipment increasingly explore renewable energy integration and more efficient pump technologies to reduce environmental impact. Automated systems support these efforts by reducing wasted energy and ensuring optimal use of resources. Energy recovery systems and smart scheduling can also help align production cycles with periods of lower energy costs or availability of renewable power.

Future Trends in Energy Optimization and Automation

The future of freeze-drying equipment for instant meals lies in smarter energy management and deeper automation. Artificial intelligence and machine learning models are being tested to predict drying curves and optimize cycle parameters, further reducing energy consumption. Advanced sensors may allow real-time moisture monitoring, leading to shorter cycles without compromising safety or quality. Integration with Industry 4.0 platforms will enable better resource allocation and predictive analytics, making the entire freeze-drying process more energy-efficient and reliable. These advancements are expected to make freeze-drying a more sustainable option for large-scale instant meal production in the coming years.

Summary of Energy and Automation Aspects

To consolidate the discussion, the table below provides an overview of how energy consumption and automation affect freeze-drying equipment for instant meals:

| Category | High Energy Impact | Automation Contribution |

|---|---|---|

| Electricity-intensive cooling | Optimized start/stop controls | |

| Vacuum Maintenance | Continuous pump operation | Dynamic regulation reduces excess |

| Sublimation Heating | Largest power demand | Precise control prevents waste |

| Condensation | Cooling requirements add load | Energy recovery mechanisms |

| Labor Involvement | Manual supervision increases cost | Automated operation minimizes labor |

| Batch Consistency | Variability without control | Stable, repeatable outcomes |

| Environmental Impact | High if inefficient | Improved with optimized systems |

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China