How does Freeze-Drying Equipment for Aquatic Feed affect the nutritional value of aquatic feed?

Freeze-drying technology, as an efficient water removal method, can remove water by sublimation at low temperature, avoiding the damage of heat-sensitive nutrients in aquatic feed caused by high temperature process. Compared with traditional drying methods, Freeze-Drying Equipment for Aquatic Feed can significantly maintain the nutritional value of aquatic feed. The specific effects are as follows:

(1) Retaining protein and amino acids

Protein in aquatic feed is the main source of growth for fish and other aquatic animals. In the traditional heat drying process, protein is easily denatured at high temperature, resulting in the loss of amino acids and decreased digestion and absorption rate. Freeze drying removes water under low temperature and low pressure conditions, which can effectively avoid protein denaturation, thereby preserving its original structure and biological activity to the greatest extent. Maintaining the integrity of protein helps aquatic animals to better digest and absorb, thereby improving growth rate and health.

(2) Retaining vitamins and minerals

Aquatic feeds are rich in water-soluble vitamins (such as B vitamins and vitamin C) and fat-soluble vitamins (such as vitamins A, D, and E). These vitamins are easily degraded during the traditional hot air drying process, resulting in a decrease in their nutritional value. Freeze drying can effectively retain these sensitive components by avoiding high temperature exposure. Aquatic feeds processed by freeze drying technology have obvious advantages in retaining vitamins and minerals, which is crucial for improving the immunity of aquatic animals and promoting their growth and reproduction.

(3) Preventing fat oxidation

Aquatic feeds usually contain a high fat content (especially fish meal and fish oil rich in omega-3 fatty acids). Fat is easily oxidized under the action of high temperature and oxygen, producing harmful peroxides and free radicals, which reduce the nutritional value of the feed and affect the health of aquatic animals. Freeze drying equipment reduces the occurrence of oxidation reactions by performing low-temperature treatment in a vacuum environment, thereby effectively retaining unsaturated fatty acids in aquatic feeds, especially omega-3 fatty acids that are beneficial to the health of aquatic animals.

(4) Improving the bioavailability of aquatic feed

Freeze drying not only preserves the nutrients in aquatic feed, but also changes the structure of the feed, making it easier for aquatic animals to digest and absorb. Traditional drying methods may cause the feed particles to harden, reducing their efficiency in being ingested by animals. Freeze drying improves the palatability and digestibility of the feed by maintaining the cell structure and particle morphology of the feed.

What differences should be paid attention to when handling different types of aquatic feed?

Different types of aquatic feed vary greatly in terms of raw material composition, water content, fat content, etc., which requires freeze drying equipment to be able to adjust accordingly according to specific production needs. The flexibility of Freeze-Drying Equipment for Aquatic Feed enables it to cope with these differences, which are as follows:

(1) Differences between low-fat and high-fat feed

Low-fat feed (such as plant-based feed) and high-fat feed (such as fish meal or feed with high oil content) have different handling requirements during the freeze drying process. High-fat feeds are prone to oil precipitation and aggregation during freeze drying, which may cause uneven drying of feed particles and even affect their quality. Therefore, freeze drying equipment needs to precisely control temperature, pressure and time to prevent oxidation or destruction of fat components during the drying process. In contrast, low-fat feeds have a lower risk of oxidation during drying due to their lower fat content, and the equipment can use a higher sublimation temperature to improve drying efficiency.

(2) Differences in particle morphology and particle size

Different types of aquatic feeds have different particle morphologies and particle sizes. For example, feeds with larger particles (such as some granular fish feeds) may require longer sublimation times and lower heating rates during freeze drying to ensure that the internal moisture can be evenly removed. Small particle feeds may require more efficient drying parameters to avoid over-drying or structural damage of the particles. Freeze drying equipment needs to adjust drying conditions according to the characteristics of different particles to ensure uniform drying effects.

(3) Differences in water-soluble components

Some aquatic feeds are rich in water-soluble components (such as amino acids, minerals and B vitamins, etc.), which may be destroyed by changes in temperature and humidity during freeze drying. Therefore, freeze-drying equipment must pay special attention to temperature and time control when processing these ingredients to avoid the loss of ingredients. For these highly water-soluble ingredients, the heating rate during the freeze-drying process should be kept low to ensure the stability of the ingredients.

(4) Differences between compound feed and single-ingredient feed

Compound feed is usually made from a mixture of multiple raw materials (such as fish meal, plant meal, animal fat, etc.). When freeze-drying, it is necessary to adjust the temperature according to the physical and chemical properties of different ingredients. For example, the freeze-drying requirements of protein and fat are different from those of plant fiber or minerals. Freeze-drying equipment needs to flexibly adjust temperature, pressure and humidity to ensure that all ingredients are dried evenly and effectively.

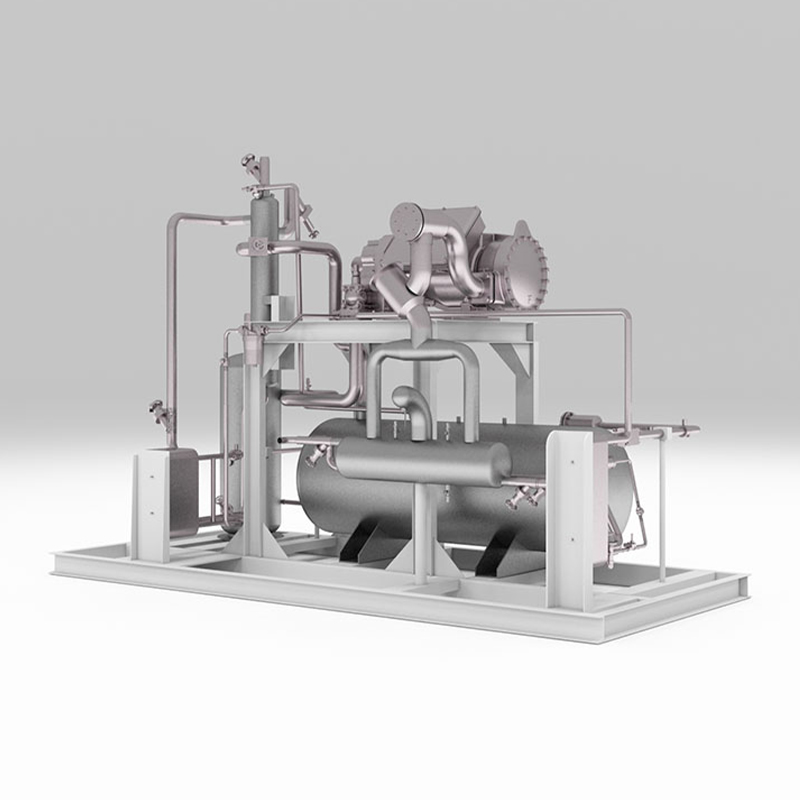

Provide personalized customization according to customer needs

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd., with its many years of experience in freeze-drying equipment research and development and production, is able to provide customers with highly personalized solutions to meet the special needs of different types of products, operating requirements, scale structures, etc. During the design and delivery of equipment, the company combines the specific requirements of customers to ensure that the functions and performance of each device can perfectly match the customer's production scenario.

(1) Customized equipment design

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd is committed to providing customized freeze-drying equipment for customers of different industries and sizes. Whether it is household-grade equipment for small laboratory research or high-efficiency equipment required for large-scale industrial production, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd can provide personalized design according to customer needs. For example, for industries such as aquatic feed, pet food, pharmaceuticals, and cosmetics, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd can design suitable freeze-drying systems based on different raw material characteristics and production goals.

(2) Personalized customization and production requirements

During the equipment customization process, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. provides tailor-made design solutions based on the customer's specific operational requirements, product scale, processing capacity and other needs. For different raw materials, such as aquatic feed, fragrance products, nutritional supplements, etc., Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. can adjust the configuration parameters of the freeze-drying equipment according to the characteristics of each product. The equipment structure, operation mode, drying time, temperature control and other aspects will be optimized according to specific needs to ensure the quality of the final product and production efficiency.

(3) Comprehensive technical support

During the equipment delivery and implementation process, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. not only provides detailed production drawings, factory layout plans and process test samples, but also provides comprehensive technical support during the equipment installation and commissioning stages. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s team will fully participate in the on-site commissioning and verification of the equipment to ensure that the equipment operates stably and meets the customer's various production standards. At the same time, the company also provides customers with operational training and after-sales support to help customers quickly master the skills of using the equipment and achieve efficient production.

(4) Full process support from R&D to production

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s freeze-drying equipment covers different application scenarios from household to industrial level, and can be widely used in scientific research institutions, laboratories and large-scale production lines. From initial product development to final industrial production, the equipment provided by Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. can flexibly adapt to different production needs and help customers maintain efficient production quality and technical support at every stage from research to production. Especially during new product development, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. leverages its extensive technical expertise and innovative capabilities to ensure clients can achieve a smooth transition from laboratory to industrial production in a short period of time.

Through these customized services, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. not only ensures the efficiency and stability of its freeze-drying equipment but also enables clients to tailor solutions to their specific needs, thereby improving production efficiency, optimizing production processes, and ensuring product quality.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China