How does freeze-drying affect the performance and stability of polymers and coatings?

Freeze-Drying Equipment for Polymers and Coatings plays a crucial role in polymer and coating processing. Freeze-drying utilizes low temperatures and a vacuum environment to remove solvents or water, avoiding the thermal damage associated with traditional drying methods while ensuring long-term product stability. However, the freeze-drying process may affect the properties of polymers and coatings. The following is an analysis of several aspects:

Structural and Molecular Stability

After polymers and coatings undergo low-temperature freezing in freeze-drying equipment for polymers and coatings, water is removed by sublimation, a process that has minimal impact on the polymer's molecular structure. Compared to high-temperature drying, freeze-drying maintains the molecular integrity of polymers, particularly for heat-sensitive polymers such as polylactic acid (PLA) or polyvinyl alcohol (PVA), which may degrade or melt at high temperatures. However, improper temperature control during freeze-drying can result in microcracks or an uneven surface structure on the polymer surface.

Surface Quality and Adhesion

Freeze-Drying Equipment for Polymers and Coatings can also affect the surface quality of coatings, particularly in coating applications requiring high uniformity and good adhesion. Coatings can experience problems such as bubbles and cracks during the freeze-drying process, especially when the sublimation rate is too rapid. For example, incomplete removal of solvent from the coating material can result in a rough, brittle, or uneven surface. Therefore, careful control of temperature and pressure when using freeze-drying equipment is crucial for achieving a high surface quality.

Mechanical Properties

The freeze-drying process significantly impacts the mechanical properties of polymers and coatings. Temperature and pressure control in freeze-drying equipment directly influences the mechanical properties of polymers. Some polymers, such as thermoset resins, exhibit increased tensile strength and elasticity after freeze-drying. However, for some coatings, freeze-drying can lead to surface brittleness and reduced adhesion. Proper control of freeze-drying time and temperature can maintain mechanical properties while preventing polymer deformation or coating failure.

Long-term Stability

Freeze-drying equipment effectively maintains the long-term stability of polymers and coatings, especially under extreme storage conditions. By preventing degradation and aging at high temperatures, polymers and coatings often have a longer shelf life after freeze-drying. For example, drug coatings or biomaterial coatings, after freeze-drying, can maintain stable properties during long-term storage and are less susceptible to environmental changes.

Do different types of polymers and coatings require different freeze-drying conditions?

Freeze-drying equipment for polymers and coatings is not a one-size-fits-all solution. Different freeze-drying conditions are typically required for different polymers and coatings. The different properties of polymers and coatings, including molecular weight, chemical composition, and thermal stability, may affect the temperature, pressure, and time parameters required during the freeze-drying process.

Thermal Sensitivity of Polymers

Different polymers have varying temperature sensitivities. Thermoplastic polymers (such as polyethylene and polypropylene) require lower temperatures and slower sublimation rates during freeze-drying to prevent melting or deformation. While thermosetting polymers (such as epoxy resins) have relatively stable molecular structures, precise temperature control is still required to prevent structural changes caused by overheating. Freeze-drying equipment for polymers and coatings must have robust temperature control systems to accommodate these varying requirements.

Coating Uniformity and Adhesion

Coating materials such as metal coatings, ceramic coatings, and polymer coatings often have different processing requirements. Metal coatings may experience surface pores or cracks during the freeze-drying process, requiring lower temperatures and slower sublimation rates to ensure surface integrity. Polymer coatings, on the other hand, require optimized sublimation rates to ensure surface uniformity. Freeze-drying equipment for polymers and coatings should have flexible configurations to handle various coating types and ensure optimal freeze-drying results for each material.

Solvents and Molecular Weight

The type and molecular weight of the solvent used in polymers and coatings also impact the freeze-drying process. For low-molecular-weight polymers, the freeze-drying process is generally simpler, as the solvent is more volatile. However, high-molecular-weight polymers may require longer freeze-drying times and more precise temperature control. The volatility of the solvent also affects the sublimation rate. The more volatile the solvent, such as ethanol or acetone, the more stringent the pressure and temperature control requirements during the freeze-drying process.

The Importance of Temperature and Pressure Control

Freeze-Drying Equipment for Polymers and Coatings requires temperature and pressure adjustment during the freeze-drying process based on the different properties of the polymer and coating. For example, high temperatures may cause the polymer to melt, resulting in material loss, while too low a temperature may prevent the solvent from sublimating effectively. Proper temperature control and vacuum adjustment ensure complete solvent removal while maintaining the physical properties and structure of the polymer and coating.

How can freeze-drying equipment for polymers and coatings improve production efficiency and reduce energy consumption?

In the production of polymers and coatings, the application of freeze-drying equipment for polymers and coatings not only ensures material quality and properties, but also requires optimizing production efficiency and reducing energy consumption. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. offers extensive experience and technological innovation in this area. Combining intelligent equipment with modern production techniques, they have brought groundbreaking solutions to the polymer and coating industries.

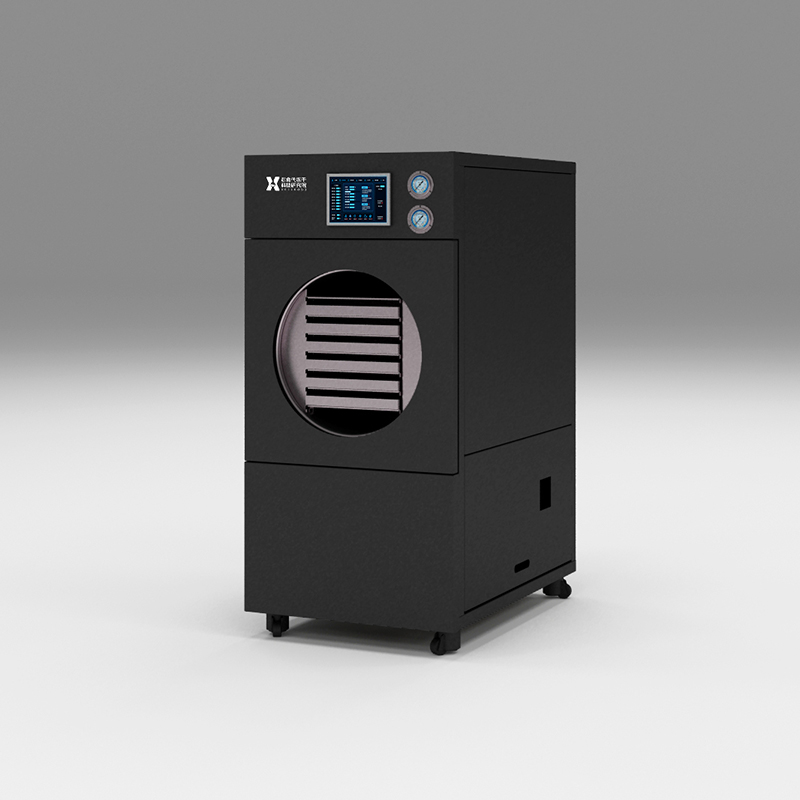

Intelligent Control Systems Improve Production Efficiency

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. is dedicated to integrating intelligent control systems into freeze-drying equipment, significantly improving production efficiency. By integrating intelligent algorithms, freeze-drying equipment for polymers and coatings monitors key parameters such as temperature, humidity, and pressure in real time and automatically adjusts operating conditions. This system precisely controls every detail of the freeze-drying process, tailored to the specific polymer or coating type. This intelligent control system not only reduces manual errors and instability but also ensures that each batch of material is freeze-dried under optimal conditions through efficient adaptive adjustments, thereby improving production efficiency.

The intelligent freeze-drying equipment used by Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. automatically selects the appropriate freeze-drying conditions for different polymer or coating applications, further reducing manual intervention and time waste. This is crucial for large-scale production, significantly shortening production cycles and increasing overall production capacity.

Heat Recovery and Energy-Saving Design

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s equipment also places special emphasis on energy-saving design, employing efficient heat recovery technology to reduce energy consumption. During the freeze-drying process, a significant amount of heat energy is used to sublimate water or solvents. By recovering and reusing this heat, overall energy consumption can be effectively reduced.

Freeze-Drying Equipment for Polymers and Coatings is also equipped with a highly efficient cooling system that quickly reduces the internal temperature of the equipment, avoiding unnecessary energy waste. This concept, incorporated into Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s equipment design, supports sustainable production, not only economically reducing operating costs but also providing an environmentally friendly production solution.

Multi-stage Freeze-drying Optimizes Production Process

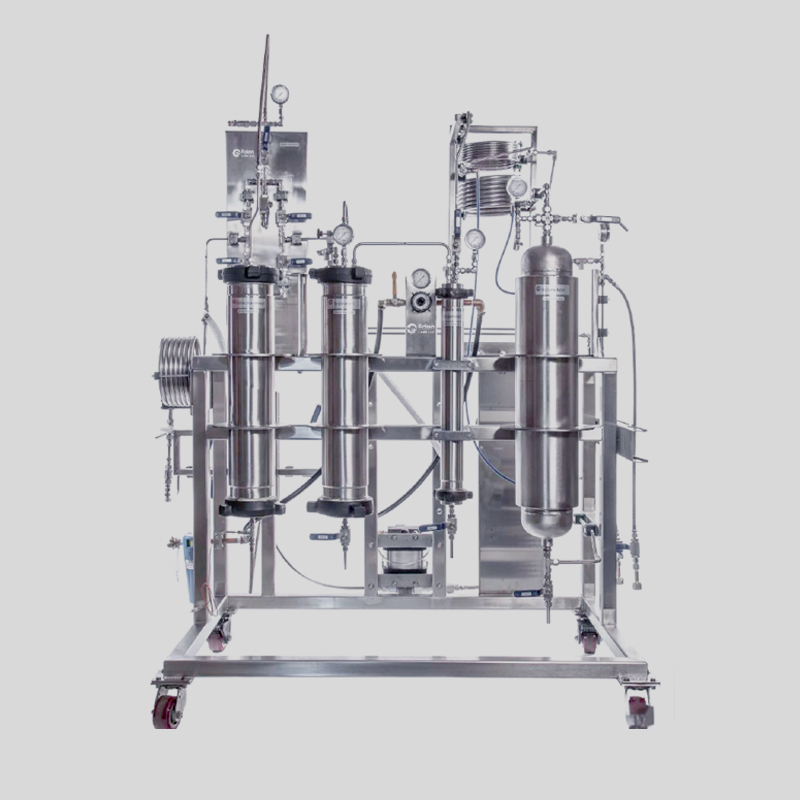

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. also utilizes multi-stage freeze-drying technology in its equipment, which is particularly important for freeze-drying polymers and coatings. This staged freeze-drying process allows the equipment to finely adjust temperature and pressure across multiple stages, thereby improving freeze-drying efficiency. For example, during the initial freeze phase, the equipment uses a lower temperature and vacuum to rapidly freeze the water or solvent, preparing for the sublimation phase. After the sublimation phase, the equipment adjusts temperature and pressure to ensure complete solvent removal without affecting the structure and properties of the polymer and coating.

This multi-stage freeze-drying process not only improves freeze-drying efficiency but also ensures consistent quality of the polymer and coating. Through precise temperature and pressure control, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s equipment minimizes energy loss, lowers unit production costs, and maintains an efficient production schedule.

Modular Design and Scalable Production

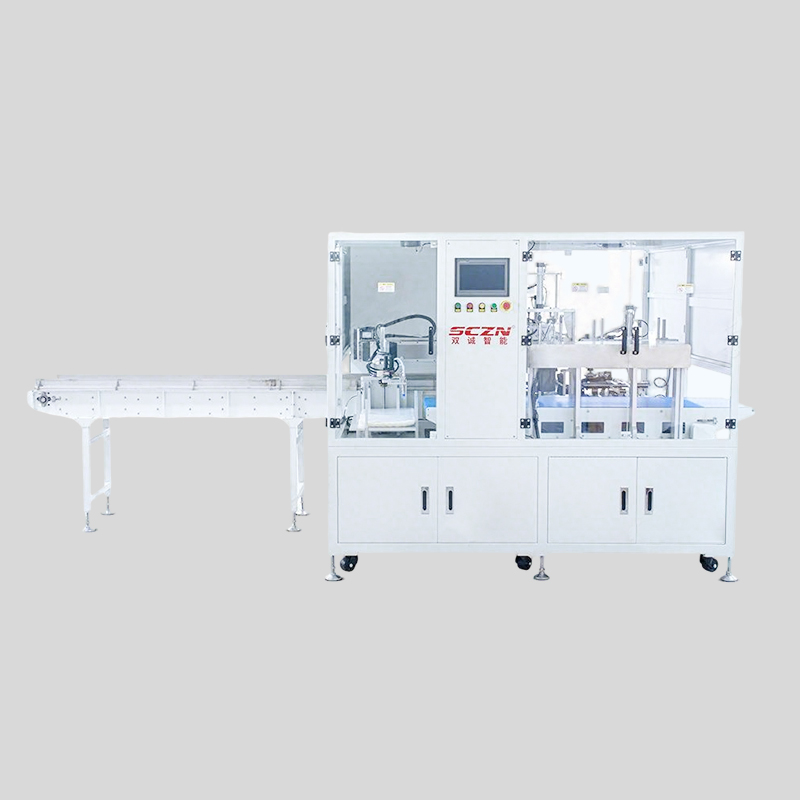

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s freeze-drying equipment for polymers and coatings features a modular design, allowing for flexible expansion based on customer production needs. For companies requiring large-scale production, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s equipment can provide higher production capacity by connecting multiple freeze-drying units in parallel. This modular design not only reduces equipment idle time but also allows for flexible load adjustment based on production needs, avoiding energy waste.

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.'s freeze-drying equipment also maximizes production efficiency through an optimized production scheduling system. This system automatically adjusts the operating status of each freeze-drying unit based on different production tasks, avoiding idle equipment and unnecessary downtime.

Innovation and Environmental Sustainability

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. consistently prioritizes environmental sustainability. Its freeze-drying technology leverages intelligent management and energy-saving equipment to minimize the environmental impact of production. Through continuous technological research and development, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. not only improves production efficiency and reduces energy consumption, but also incorporates environmentally friendly design into the core of its freeze-drying equipment. The customized freeze-drying solutions provided by Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. help food companies, polymer manufacturers, and other organizations achieve green production goals, improving production efficiency while supporting sustainable development.

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. also strategically collaborates with experts from Chinese universities and food science schools to continuously innovate freeze-drying technology and promote overall advancements in freeze-drying technology within related industries. Through this in-depth collaboration, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. is able to provide global customers with the latest freeze-drying technology resources while ensuring the quality of their products and minimizing their environmental impact.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China