When selecting freeze-drying equipment, the specific characteristics of the plant extracts being processed must be carefully considered. Plant extracts can differ widely in terms of their chemical composition, moisture content, and stability, all of which can influence how the freeze-drying process should be carried out. For example, some plant extracts may have high moisture content, requiring a longer drying time to achieve the desired results, while others may be more sensitive to heat and pressure and require more precise control during the sublimation phase. Plant extracts such as essential oils, which are often derived from flowers, herbs, or fruits, contain volatile compounds that are sensitive to temperature fluctuations. Freeze-drying is particularly advantageous for these extracts because it allows the delicate compounds to remain intact. For plant extracts with lower moisture content or those that are less sensitive to temperature, freeze-drying equipment needs to be optimized for efficiency and speed to reduce the overall production time. At Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd., we recognize the diversity of plant extracts and the need for equipment that can be finely tuned to meet these varying demands. Our intelligent freeze-drying systems offer customizable features that cater to the unique needs of different plant materials, from those requiring gentle temperature control to those needing higher throughput to handle larger batches. By understanding the chemical composition and moisture content of each extract, we ensure that our freeze-drying equipment is optimized for the best possible preservation and quality outcomes, no matter the type of plant extract.

The production scale is one of the most important factors to consider when selecting freeze-drying equipment. For smaller-scale operations, a compact freeze-dryer with lower batch capacity might be suitable. These units allow for more flexibility in testing different formulations and materials on a smaller scale, offering lower initial investment costs and greater adaptability. However, small-scale operations might face limitations in terms of throughput, which can be a bottleneck when larger quantities are needed. On the other hand, large-scale industrial operations require freeze-drying systems with high processing capacities that can handle significant volumes of plant extracts. Larger units often feature multiple shelves or trays for processing larger batches, as well as higher freezing and drying rates to ensure efficient operation. For manufacturers aiming to scale up production, it’s crucial to select equipment that maintains high throughput without sacrificing quality. The right equipment should offer both speed and consistency to ensure the production process remains streamlined. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. offers a range of freeze-drying systems that cater to both small-scale and large-scale operations. We can help us assess our production needs to determine whether a smaller batch-oriented unit or a larger, high-capacity system would be more appropriate. Our flexible equipment allows for easy scalability, meaning that as production demands grow, we can transition smoothly to larger systems without requiring a complete overhaul of our existing equipment. The goal is always to match the scale of production with the equipment’s capabilities, ensuring maximum efficiency and cost-effectiveness.

Energy consumption is a critical factor when evaluating freeze-drying equipment, especially given that the freeze-drying process can be quite energy-intensive. The ability to reduce energy consumption while maintaining high levels of efficiency is essential not only for lowering operational costs but also for minimizing the environmental impact of production. Energy-efficient equipment can significantly reduce both electricity bills and the carbon footprint of the manufacturing process. Many traditional freeze-drying systems can be inefficient, using large amounts of energy to maintain the low temperatures required for freezing and sublimating plant extracts. However, modern advancements in freeze-drying technology, such as heat recovery systems and more efficient refrigeration, have made it possible to cut down on the energy required during these stages of the process. These innovations allow for greater control over temperature regulation, ensuring that energy is only used when necessary and reducing waste. At Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd., we place a strong emphasis on developing freeze-drying systems that are not only high-performing but also energy-efficient. Our equipment features cutting-edge technologies such as heat recovery and thermal insulation, which help minimize energy usage without compromising performance. We work closely with us to ensure that the equipment we select aligns with our sustainability goals, helping us reduce both energy consumption and environmental impact while maintaining the highest quality standards in the production of plant extracts.

The accuracy of temperature and pressure control during the freeze-drying process is crucial to preserving the quality of plant extracts. Temperature and pressure conditions must be precisely regulated throughout the process to ensure that plant extracts retain their bioactive compounds and integrity. In the freezing stage, temperatures need to be low enough to solidify the extract without causing ice crystal damage. During the sublimation phase, pressure must be lowered enough to allow moisture to sublimate directly from solid to gas without melting. Freeze-drying systems with poor temperature or pressure control may cause uneven drying, which can lead to the degradation of sensitive compounds, resulting in a lower-quality product. Therefore, equipment that provides real-time monitoring and adjustment of temperature and pressure is essential. Advanced freeze-drying systems also offer automatic adjustment features that allow the equipment to adapt to changes in batch composition or environmental conditions, further ensuring the consistency and quality of the product. At Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd., our intelligent freeze-drying systems feature advanced sensors and automation that allow for precise control over temperature and pressure throughout each phase of the process. This ensures that plant extracts are dried under optimal conditions, minimizing the risk of thermal damage while maximizing product yield and preserving the bioactive compounds. With our equipment, we can achieve the highest levels of quality control, enabling plant extract manufacturers to meet their specific production needs efficiently.

One of the most significant factors influencing the overall effectiveness of freeze-drying equipment is drying time. Longer drying cycles increase the time it takes to produce a batch of plant extracts, which can lead to higher operational costs and potentially limit production capacity. In contrast, faster drying cycles can boost productivity, but only if the quality of the extract is not compromised in the process. Achieving the optimal balance between drying time and product quality is key to improving efficiency. Some factors that influence drying time include the type of plant extract being processed, the moisture content of the extract, and the overall capacity of the freeze-dryer. For instance, materials with high moisture content generally require longer drying times, whereas those with lower moisture content may dry more quickly. However, no matter the material, reducing drying time without sacrificing the quality of the final product is always a priority. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. has invested in innovative technologies that reduce drying time without compromising the integrity of the plant extracts. Our equipment features automated monitoring systems that adjust parameters such as temperature and pressure dynamically, ensuring that the freeze-drying process runs as efficiently as possible. This means we can reduce production time and increase output while maintaining the high quality and purity of the extracts. The result is greater productivity, lower costs, and improved profitability for manufacturers.

When selecting freeze-drying equipment, the initial investment is a significant factor to consider, but it is equally important to assess the long-term return on investment (ROI). Freeze-drying equipment can represent a substantial capital expenditure, so it is crucial to evaluate its potential to increase efficiency, yield, and product quality over time. High-quality freeze-drying systems that are energy-efficient and durable can pay for themselves through cost savings and improved output in the long run. The total cost of ownership includes not only the upfront price of the equipment but also ongoing operational expenses such as maintenance, energy consumption, and labor. Equipment that offers higher energy efficiency, easier maintenance, and greater reliability can significantly reduce the total cost of ownership. By improving the quality and shelf life of the plant extracts, manufacturers can charge a premium for their products, which can further increase profitability. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. provides cost-effective freeze-drying solutions that maximize ROI. Our intelligent freeze-drying systems are designed to minimize energy usage, reduce maintenance costs, and extend the lifespan of the equipment. With our assistance, we can calculate the total cost of ownership and projected ROI for different types of freeze-drying equipment, ensuring that we make an informed decision that aligns with both short-term and long-term business goals.

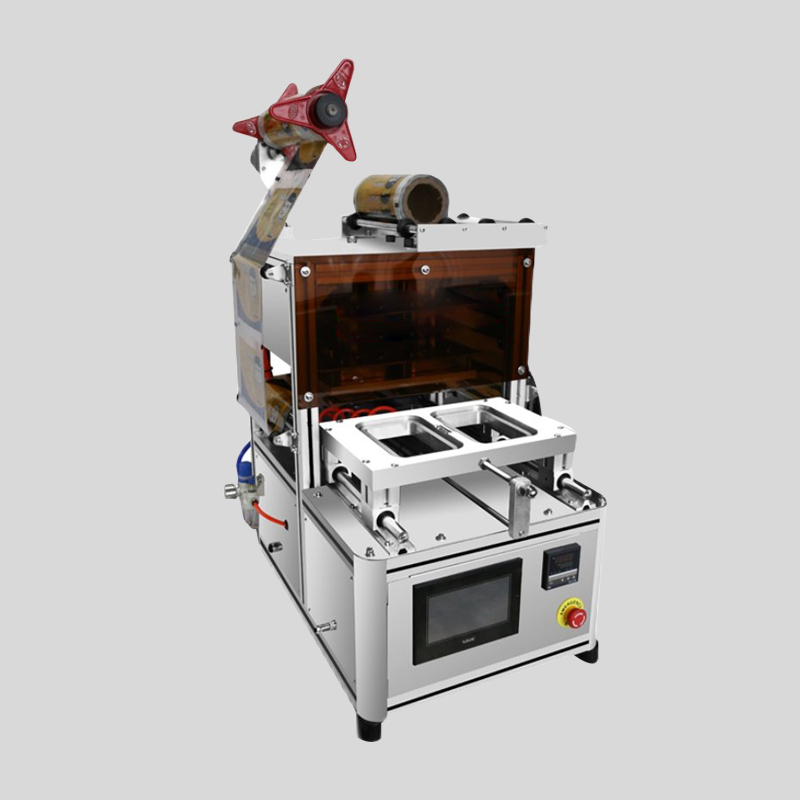

Vacuum Nitrogen Filling Packaging Machine for Plant Extracts

Vacuum Nitrogen Filling Packaging Machine for Plant Extracts

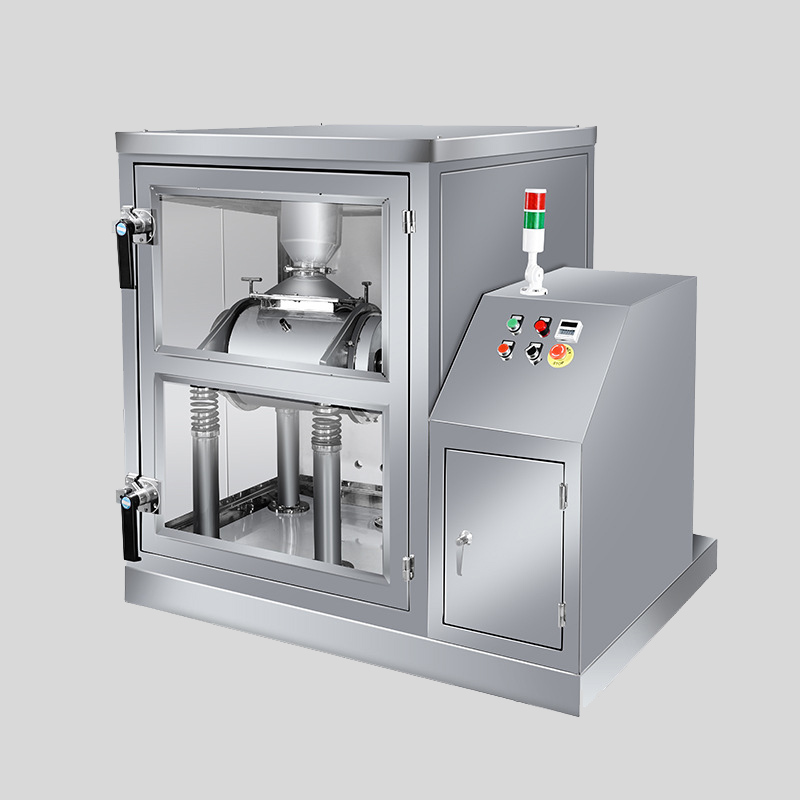

Three-Dimensional Mixer for Plant Extracts

Three-Dimensional Mixer for Plant Extracts

Airflow Pulverizer for Plant Extracts

Airflow Pulverizer for Plant Extracts

Vacuum Freeze Dryer for Plant Extracts

Vacuum Freeze Dryer for Plant Extracts

Membrane Separation Device for Plant Extracts

Membrane Separation Device for Plant Extracts

Molecular Distillation System for Plant Extracts

Molecular Distillation System for Plant Extracts

Countercurrent Extraction Tank for Plant Extracts

Countercurrent Extraction Tank for Plant Extracts

Ultrasonic Wall-Breaking Machine for Plant Extracts

Ultrasonic Wall-Breaking Machine for Plant Extracts