How Do Advanced Freeze-Drying Technologies Enhance Active Ingredient Stability?

Maintaining the potency and bioactivity of sensitive compounds is a critical challenge in pharmaceuticals, nutraceuticals, and functional foods. Active Ingredient Freeze-Drying Solutions leverage precision engineering and controlled environments to protect heat-labile APIs, probiotics, enzymes, and herbal extracts. Through specialized equipment and advanced monitoring, manufacturers can ensure consistent efficacy, extended shelf life, and reliable product quality across various formulations and production scales.

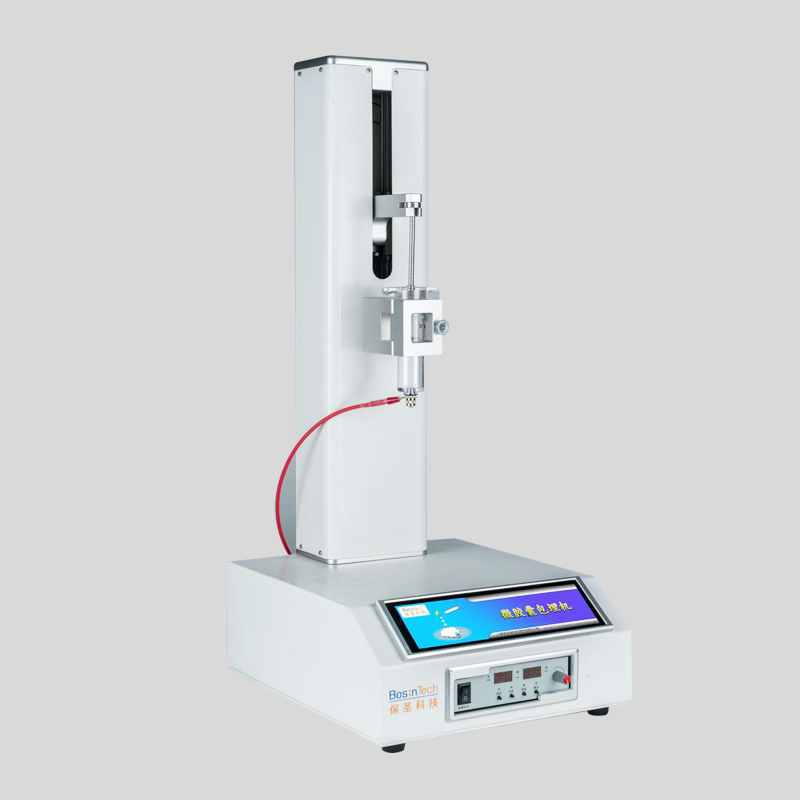

Precision Freeze-Dryers for Sensitive Ingredients:

Active Ingredient Freeze-Drying Solutions rely on specialized low-temperature vacuum freeze-dryers designed to prevent thermal or oxidative damage to heat-labile APIs, probiotics, enzymes, and herbal extracts. These precision systems carefully regulate sublimation rates and temperature profiles, ensuring that delicate molecular structures remain intact. By maintaining the integrity of these sensitive compounds, manufacturers can guarantee consistent potency, bioactivity, and efficacy in the final product. The technology also supports multi-component formulations, allowing complex blends to retain full functionality without compromising stability or quality.

Online Moisture and Oxygen Monitoring:

Real-time monitoring is a critical component of Active Ingredient Freeze-Drying Solutions. Advanced sensors continuously track residual moisture levels and oxygen exposure during the freeze-drying process, providing immediate feedback on process deviations. This capability ensures that moisture-sensitive probiotics or oxidation-prone herbal extracts remain stable and effective throughout production. By detecting potential issues early, manufacturers can adjust drying parameters on the fly, safeguarding product quality, reproducibility, and shelf life while minimizing waste and batch failures.

Customizable Processing Modules:

The modular design of Sieno’s equipment enables manufacturers to adapt freeze-drying processes for different ingredient types, batch sizes, and product formats. Active Ingredient Freeze-Drying Solutions can be applied to powders, tablets, capsules, or concentrated extracts, each processed under optimized conditions to maximize bioactive retention and dosage accuracy. This flexibility allows for tailored product formulations, supports innovation in nutraceuticals and pharmaceuticals, and ensures that sensitive ingredients maintain their functional properties across all formats.

Nitrogen Protection and Controlled Atmospheres:

Integration of nitrogen flushing or inert gas systems is another key feature of Active Ingredient Freeze-Drying Solutions. By replacing oxygen with nitrogen during drying and packaging, oxygen-sensitive compounds are protected from oxidative degradation. This approach preserves potency, extends product shelf life, and eliminates the need for chemical stabilizers or preservatives. Controlled atmospheres also enhance product consistency, allowing brands to maintain quality standards across multiple production runs.

Scalable and Energy-Efficient Operation:

From laboratory R&D to pilot-scale production and full industrial manufacturing, Sieno’s freeze-drying equipment ensures uniform temperature, vacuum, and drying cycles across batches. Energy-efficient designs reduce operational costs while maintaining high reproducibility and stability of Active Ingredient Freeze-Drying Solutions. Manufacturers can confidently scale production volumes without sacrificing product performance, making it possible to meet increasing market demand while adhering to strict regulatory and quality requirements.

By combining precision freeze-drying, real-time monitoring, modular adaptability, and controlled atmospheres, Active Ingredient Freeze-Drying Solutions provide manufacturers with reliable, high-quality methods to produce sensitive bioactive compounds. This approach not only safeguards product efficacy but also supports innovation and scalability across global nutraceutical, pharmaceutical, and functional food markets.

How Do Active Ingredient Freeze-Drying Solutions Preserve Bioactivity and Efficacy?

Stability and potency are critical for pharmaceutical, nutraceutical, and biotech products. Active Ingredient Freeze-Drying Solutions ensure that sensitive molecules, including APIs, enzymes, probiotics, and herbal extracts, maintain their structural integrity throughout production and storage.

Protection of Molecular Structure:

The low-temperature sublimation process in Active Ingredient Freeze-Drying Solutions removes moisture under vacuum without exposing sensitive ingredients to high heat, which could otherwise denature proteins, degrade enzymes, or compromise the viability of probiotics. This gentle method preserves the delicate three-dimensional structure of bioactive molecules, ensuring they maintain full functionality. Herbal extracts retain their rich polyphenols, flavonoids, volatile oils, and other phytochemicals, preserving both their natural potency and therapeutic efficacy. Such structural protection is critical for complex formulations where multiple sensitive ingredients coexist, allowing manufacturers to deliver highly effective nutraceuticals, functional foods, or pharmaceutical preparations with predictable performance.

Consistent Bioactivity:

With Active Ingredient Freeze-Drying Solutions, each production batch delivers reproducible concentrations of active compounds, guaranteeing that every unit of the product provides reliable health or therapeutic benefits. Freeze-dried enzymes retain their full catalytic activity, ensuring proper metabolic or biochemical functions when consumed. Probiotics maintain high viability and functional integrity, supporting digestive health, immune modulation, and microbiome balance. This consistency is especially valuable for products targeting sensitive populations such as infants, elderly, or patients requiring precise dosing, giving brands confidence in meeting both regulatory requirements and consumer expectations.

Extended Shelf Life:

By effectively removing moisture, freeze-dried ingredients are naturally resistant to microbial growth, oxidation, and chemical degradation. Active Ingredient Freeze-Drying Solutions dramatically extend the stability of proteins, probiotics, enzymes, and plant extracts without the need for chemical preservatives or stabilizers. This extended shelf life is essential for manufacturers who distribute products globally, allowing for long-term storage, reduced cold-chain dependency, and compliance with international regulatory standards. Moreover, it ensures that product claims, such as potency, viability, or functional performance, remain valid over time, enhancing consumer trust and brand credibility.

These advantages make freeze-drying indispensable for high-value active ingredients, allowing manufacturers to deliver safe, potent, and effective products that meet rigorous quality standards.

How Does Sieno Enable Efficient and Reliable Active Ingredient Freeze-Drying Solutions?

Sieno provides a complete suite of equipment and process support designed to optimize every stage of Active Ingredient Freeze-Drying Solutions production, from research to industrial-scale manufacturing.

Specialized freeze-drying machinery: Sieno’s equipment, including low-temperature vacuum freeze-dryers, online moisture monitors, and nitrogen protection systems, ensures that moisture-sensitive and oxygen-sensitive ingredients are fully preserved. Each unit is engineered for precise control over drying parameters, guaranteeing product integrity.

Energy-efficient and reliable operation: Automation maintains stable temperature, vacuum, and pressure conditions, ensuring batch-to-batch consistency while reducing energy consumption. Nutrients, enzymes, probiotics, and herbal extracts maintain their bioactivity, flavor, and color.

Customizable configurations: Equipment accommodates a variety of volumes, ingredient types, and product formats, from small-scale R&D experiments to large-scale commercial production. This flexibility allows tailored formulations without compromising the stability or bioactivity of sensitive compounds.

End-to-end process support: Integrated solutions cover pretreatment, freeze-drying, and packaging. Online moisture monitoring and nitrogen protection enhance shelf-life and product quality. Intelligent process control reduces waste, improves efficiency, and supports sustainable production.

Green manufacturing solutions: Sieno’s equipment emphasizes energy efficiency, stable operation, and reduced environmental footprint, aligning with modern sustainability expectations while delivering high-quality, reliable freeze-dried active ingredient products.

Through specialized machinery, process optimization, and technical support, Sieno empowers brands to manufacture Active Ingredient Freeze-Drying Solutions that are potent, stable, and compliant with global quality standards, ensuring products meet both consumer expectations and industry regulations.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China