Introduction

Agriculture has always been the backbone of human civilization, providing the food and raw materials necessary for life and industry. However, one of the greatest challenges the agricultural sector continues to face is food preservation. From the moment crops are harvested, they begin to lose freshness, nutritional value, and market appeal. Traditional preservation methods—such as canning, dehydration, or chemical additives—often compromise flavor, texture, and nutrients, leaving farmers and processors searching for a more effective, sustainable solution.

Freeze drying, also known as lyophilization, has emerged as a groundbreaking technology in agricultural food preservation. By gently removing moisture from food under low temperature and vacuum conditions, freeze drying maintains the natural structure, color, flavor, and nutritional content of the product—while dramatically extending its shelf life. This process offers a modern answer to post-harvest challenges, helping to reduce food waste, retain nutritional value, and enhance product quality.

As the global demand for high-quality, convenient, and sustainable food grows, freeze drying is rapidly transforming the way agricultural products are processed, stored, and distributed. It not only opens new markets for farmers and food producers but also supports a more resilient and environmentally responsible food system.

At the forefront of this innovation is Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd, a company dedicated to integrating freeze-dried food science with intelligent equipment manufacturing. By collaborating with leading food science experts and leveraging advanced, self-developed freeze-drying technologies, Sieno provides comprehensive solutions—from raw material processing to finished product packaging. The company’s mission is to empower agricultural enterprises to achieve greater efficiency, quality, and sustainability in food production, leading the way in the modernization of agricultural processing.

What is Freeze Drying

1. Definition and Process Overview

Freeze drying, scientifically known as lyophilization, is a low-temperature dehydration process that removes water from materials after they are frozen. This is achieved by sublimation, the direct conversion of ice to vapor without passing through a liquid phase. The method preserves the physical structure, nutrients, and flavor of the product far better than other preservation techniques.

2. The Science Behind Sublimation

The key scientific principle behind freeze drying lies in phase transitions. When a product is frozen, its water content becomes ice. Under a vacuum environment, the ice turns directly into vapor when exposed to gentle heating. This process avoids the damage caused by liquid water movement in conventional drying, maintaining cellular integrity and nutritional content.

3. Comparison with Other Preservation Methods

| Parameter |

Canning |

Hot-Air Drying |

Freeze Drying (Lyophilization) |

| Temperature Range (°C) |

100–120 |

60–90 |

–40 to +40 |

| Nutrient Retention (%) |

40–60 |

50–70 |

90–98 |

| Shelf Life (Months) |

12–24 |

6–12 |

24–60 |

| Flavor & Texture Preservation |

Moderate |

Low |

Excellent |

| Product Weight Reduction (%) |

20–40 |

70–80 |

90–95 |

| Rehydration Ability |

Moderate |

Poor |

Excellent |

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd focuses on applying this scientific principle through intelligent system design. Their equipment precisely controls temperature, pressure, and time curves to ensure uniform sublimation across various agricultural products—fruits, vegetables, herbs, coffee, meat, and dairy—resulting in stable, high-quality outcomes with minimal waste.

Benefits of Agriculture Freeze Drying

1. Extended Shelf Life

Agriculture Freeze drying dramatically extends the shelf life of agricultural products while maintaining their sensory and nutritional qualities. For example, freeze-dried fruits, vegetables, and herbs can last 2–5 years under ambient conditions without refrigeration, compared to a few days for fresh produce.

| Product |

Fresh Shelf Life (Days) |

Freeze-Dried Shelf Life (Years) |

| Berries |

3–5 |

2–3 |

| Leafy Greens |

2–4 |

2–3 |

| Herbs |

5–7 |

2–5 |

| Root Vegetables |

7–10 |

3–5 |

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd provides systems capable of large-scale, uniform freeze drying that ensures extended shelf life for diverse agricultural products while reducing post-harvest losses and spoilage.

2. Preservation of Nutritional Value

Freeze drying retains vitamins, minerals, antioxidants, and other bioactive compounds far better than conventional drying. Studies show nutrient retention rates of 90–97% in freeze-dried produce compared with only 50–70% in hot-air dried foods.

| Nutrient Retention (%) |

Hot-Air Drying |

Freeze Drying |

| Vitamin C |

55–65 |

92–95 |

| Beta-Carotene |

60–70 |

90–94 |

| Polyphenols |

50–60 |

91–96 |

Sieno’s systems use precisely controlled freezing and drying parameters, ensuring optimal nutrient retention for fruits, vegetables, and sensitive crops such as berries and leafy greens.

3. Reduced Waste

By extending shelf life and reducing spoilage, freeze drying directly minimizes post-harvest losses. Farmers and processors can store, transport, and market products without the risk of rapid deterioration, significantly cutting food waste.

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd works closely with agricultural enterprises to implement tailored solutions that maximize yield and reduce waste across the supply chain, supporting both economic and environmental sustainability.

4. Enhanced Flavor and Texture

Freeze drying preserves the natural flavor, aroma, and texture of food. Unlike hot-air drying, which can produce tough, shrunken, or brittle products, freeze-dried fruits and vegetables maintain their original mouthfeel and sensory appeal.

Applications of Agriculture Freeze Drying

1. Fruits and Vegetables

Freeze drying preserves color, aroma, texture, and nutrients better than conventional drying methods. Examples include berries, tropical fruits, leafy greens, and root vegetables. These products can be used in snack foods, ingredients for cooking, or ready-to-eat meals.

| Parameter |

Fresh Fruits/Vegetables |

Hot-Air Dried |

Freeze-Dried |

| Moisture Content (%) |

70–95 |

10–15 |

1–3 |

| Vitamin Retention (%) |

100 |

55–70 |

90–97 |

| Color Deviation (ΔE) |

0 |

4–6 |

0.5–1 |

| Shelf Life (Ambient) |

3–10 days |

6–12 months |

2–5 years |

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd designs intelligent, modular systems for uniform sublimation and high product quality across industrial and small-scale operations.

2. Herbs and Spices

Freeze drying preserves volatile aromatic oils and pigments in herbs and spices, maintaining flavor, color, and convenience for culinary use. Examples include basil, mint, oregano, and chili peppers. Sieno uses multi-zone drying chambers and precise vacuum and temperature regulation to retain delicate aromas and oils.

| Preservation Parameter |

Hot-Air Dried Herbs |

Freeze-Dried Herbs |

| Aroma Compound Retention (%) |

55–70 |

90–95 |

| Color Retention (ΔE) |

4–6 |

0.8–1.5 |

| Moisture Content (%) |

10–15 |

2–4 |

| Rehydration Time (sec) |

180–300 |

30–60 |

3. Coffee and Tea

Freeze drying is used to produce instant coffee and tea, preserving aroma, flavor, and soluble compounds. Advantages of freeze-dried coffee and tea include maintaining superior flavor and aroma compared to conventional drying methods.

4. Meat and Seafood

Freeze drying preserves protein integrity, color, and flavor for meat and seafood. Examples include camping food, emergency rations, and pet food.

| Preservation Metric |

Hot-Air Dried |

Freeze-Dried |

| Protein Retention (%) |

80–85 |

95–98 |

| Fat Oxidation (mg MDA/kg) |

1.8–2.3 |

0.4–0.6 |

| Texture After Rehydration |

5/10 |

9/10 |

| Shelf Life (Ambient) |

6–12 months |

3–5 years |

Sieno integrates vacuum uniformity sensors and temperature feedback loops to maintain flavor and texture in protein-rich materials.

5. Dairy Products

Freeze drying is used for milk, cheese, yogurt to create shelf-stable powders while retaining protein structure and flavor.

| Parameter |

Spray-Dried Dairy |

Freeze-Dried Dairy |

| Lactose Crystallization (%) |

15–20 |

<5 |

| Protein Denaturation (%) |

10–15 |

2–4 |

| Rehydration Efficiency (sec) |

180 |

60 |

| Shelf Life (Ambient) |

1–2 years |

3–5 years |

Sieno’s multi-layer drying chambers with automated feeding and precise moisture control ensure high-quality dairy powders.

6. Probiotics and Cultures

Freeze drying preserves viability of probiotics, enzymes, and cultures.

| Parameter |

Air-Dried Cultures |

Freeze-Dried Cultures |

| Viable Cell Survival (%) |

40–60 |

90–99 |

| Residual Moisture (%) |

6–10 |

1–3 |

| Storage Temperature (°C) |

2–8 |

Ambient (20–25) |

| Shelf Life (Months) |

6–12 |

24–36 |

Sieno’s precisely calibrated cooling gradients maintain microbial viability for commercial and research applications.

Freeze Drying Equipment and Technology

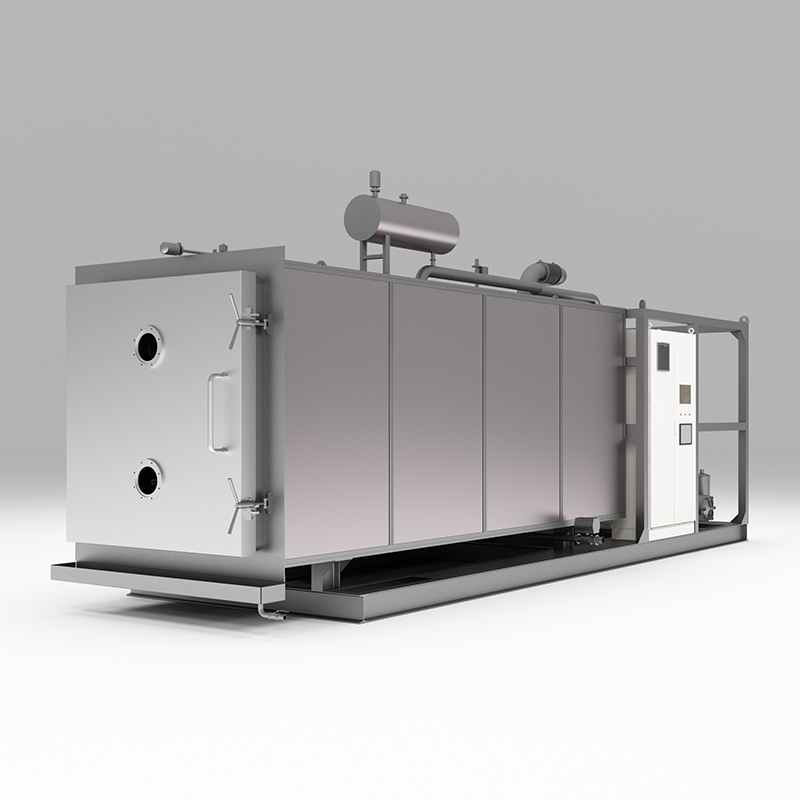

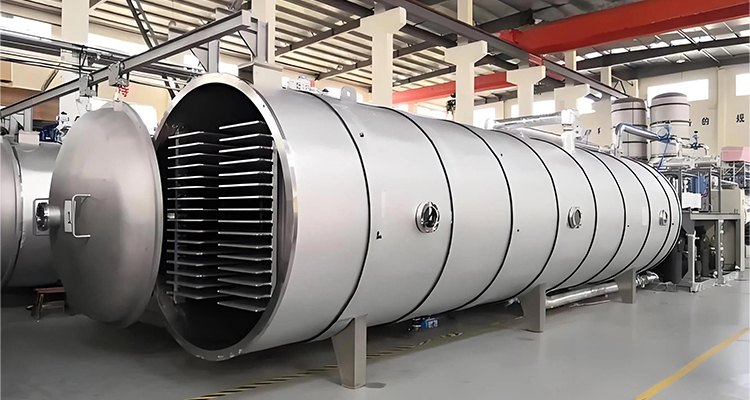

1. Types of Freeze Dryers

Agriculture freeze dryers are categorized into laboratory, commercial, and industrial systems, varying by capacity, automation, and chamber size:

| Scale |

Typical Batch Size / Capacity |

Key Features |

Common Agricultural Uses |

| Laboratory / Pilot |

<50 kg |

High precision; ultra-low condenser temps |

R&D, small-scale herbs, trace nutrients |

| Commercial / Mid-Scale |

50–1,000 kg |

Automated processes; moderate condenser sizes |

Snack fruits, spices, tea |

| Industrial / Large-Scale |

Tons per batch |

Large chambers, powerful refrigeration |

Large-scale fruits, vegetables, dairy, emergency food |

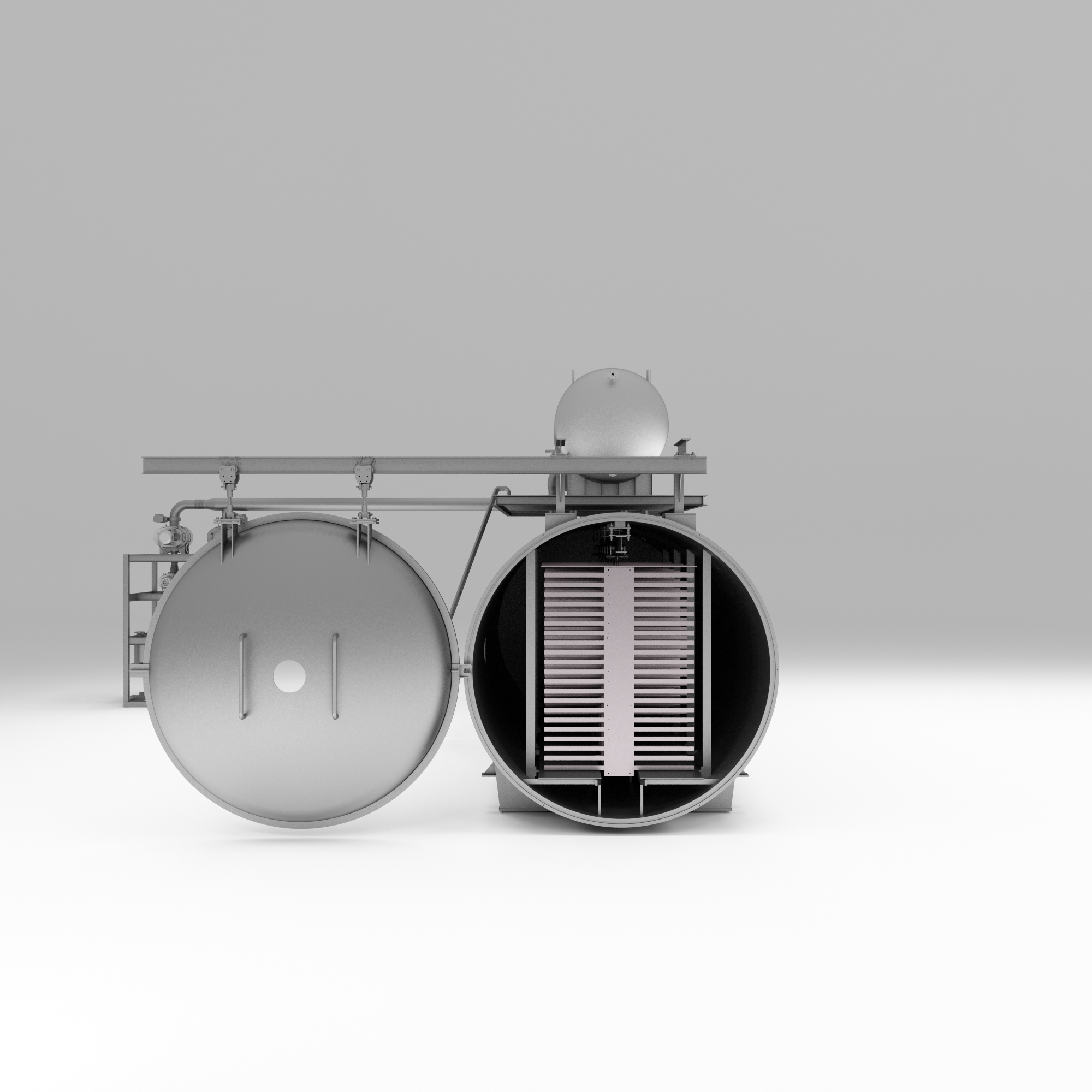

2. Key Components of a Freeze-Drying System

| Component |

Function |

Typical Parameter Ranges / Specs |

| Drying Chamber |

Holds product; controls temp/vacuum |

Shelf temp –40 °C to +50 °C; pressure 10–100 Pa |

| Condenser |

Captures sublimated moisture |

Temp –80 °C to –50 °C |

| Vacuum Pump |

Maintains low pressure |

10–100 Pa |

| Control Panel / PLC |

Automation and monitoring |

Temperature, pressure, cycle curves |

3. Advances in Freeze-Drying Technology

- Intelligent multi-zone heating for uniform drying

- Energy recovery loops to reduce operational costs

- Predictive maintenance via real-time monitoring

- Custom drying curves for sensitive products

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd integrates all these advancements to provide complete, intelligent freeze-drying solutions for agriculture.

Challenges and Considerations

1. Initial Investment Costs

One of the most notable challenges in adopting freeze-drying technology in agriculture is the high initial investment cost. Compared with traditional dehydration or refrigeration systems, a freeze dryer requires specialized vacuum systems, low-temperature refrigeration, and automated controls.

| Cost Comparison (Indicative) |

Hot-Air Dryer |

Blast Freezer + Cold Storage |

Freeze Dryer (Industrial) |

| Initial Equipment Cost (per ton/day capacity) |

Low (~US$50,000–70,000) |

Medium (~US$120,000–150,000) |

High (~US$250,000–500,000) |

Sieno addresses this challenge by offering scalable modular systems, allowing enterprises to start with smaller capacity and expand as needed.

2. Energy Consumption

Freeze drying is energy-intensive due to long drying cycles and refrigeration needs. Sieno implements energy-saving designs such as heat recovery and intelligent vacuum modulation to reduce overall consumption.

3. Technical Expertise

Operating agriculture freeze dryers requires skilled personnel who understand temperature, vacuum, and moisture dynamics. Sieno offers training programs, technical support, and automated control systems to minimize operational errors.

4. Process Time

Agriculture freeze drying cycles can range from 12–48 hours depending on the product. Sieno’s optimized drying curves and multi-chamber parallel operation reduce processing time while maintaining product quality.

5. Maintenance and Longevity

Agriculture freeze dryers require regular maintenance of vacuum pumps, refrigeration units, and control sensors. Sieno provides predictive maintenance software and service packages to reduce downtime and prolong equipment life.

6. Environmental Impact

Agriculture freeze drying uses refrigerants and electricity, contributing to environmental concerns. Sieno employs eco-friendly refrigerants, heat recovery systems, and high-insulation designs to lower carbon footprint while maintaining efficiency.

English

English  русский

русский  中文简体

中文简体

+86- (0) 519-8578 6988

+86- (0) 519-8578 6988  +86-180 6875 7376

+86-180 6875 7376  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China