Introduction

Brief overview of cosmetics freeze drying and its importance

The quest for products with potent, stable, and naturally-derived active ingredients is defining the modern beauty industry. This pursuit has brought cosmetics freeze drying equipment to the forefront of cosmetic manufacturing. Often referred to as lyophilization, this sophisticated preservation technique is rapidly becoming essential for formulating high-performance skincare and makeup products. Freeze drying works by gently removing water from a frozen product through a process called sublimation, where ice turns directly into vapor under a vacuum.

Why freeze drying is essential for preserving cosmetic ingredients

This minimal-stress process is why freeze drying is essential for preserving delicate and high-value cosmetic ingredients. Traditional preservation methods, like heat drying or adding chemical preservatives, can degrade sensitive compounds such as peptides, enzymes, probiotics, and certain plant extracts or vitamins. Freeze drying circumvents this degradation, locking in the ingredient's potency and original structure.

The growing demand for freeze-dried cosmetics

The result is a lightweight, anhydrous (water-free) product that requires no harsh chemical preservatives and boasts an exceptionally long shelf life. This ability to deliver maximum efficacy and stability has fueled the growing demand for freeze-dried cosmetics, establishing freeze drying equipment as a non-negotiable asset for any forward-thinking cosmetic enterprise looking to lead the charge in cosmetic stability and natural formulation.

Benefits of Freeze Drying Cosmetics

The process of freeze drying cosmetics offers a transformative approach to product formulation, yielding multiple advantages that resonate with both manufacturers and consumers. Achieving these benefits consistently requires state-of-the-art equipment and deep process knowledge.

Enhanced preservation of active ingredients

Freeze drying is unparalleled in maintaining the biological activity and structural integrity of heat-sensitive compounds. By removing water at low temperatures and under vacuum, it effectively prevents the degradation of potent ingredients like peptides, enzymes, and vitamins, ensuring the final product delivers maximum therapeutic benefit. Companies like Sieno Freeze-drying Technology specialize in providing intelligent freeze-drying equipment with the precise control systems necessary to optimize cycles and safeguard these delicate actives.

Extended shelf life of cosmetic products

The removal of water significantly hinders microbial growth and chemical reactions that lead to spoilage, granting the resulting anhydrous product an extended shelf life—often years—without the need for refrigeration or strong chemical stabilizers. This stability is a direct result of efficient moisture removal, a core competency ensured by the high-performance vacuum and refrigeration systems in Sieno's machines.

Improved stability and reduced degradation

The dried, porous "cake" that results from lyophilization is chemically stable. Ingredients are effectively 'frozen in time,' protecting them from degradation caused by factors like oxygen and moisture until they are reconstituted for use. This vastly improves cosmetic stability, giving manufacturers the confidence to ship and store high-value freeze-dried skincare globally.

Lightweight and easy-to-transport products

Since water is removed, the final product is significantly lighter, reducing shipping costs and environmental impact while also making the product convenient for consumers. This efficiency gain aligns with Sieno's mission to empower clients to achieve efficiency gains and the multifaceted values of environmental sustainability.

No need for harsh preservatives

The low moisture content achieved through lyophilization naturally inhibits microorganism proliferation, allowing formulators to eliminate or significantly reduce the use of undesirable chemical preservatives. This is crucial for brands targeting the "clean beauty" segment, relying instead on the inherent stability provided by advanced processing technology.

Types of Freeze Drying Equipment for Cosmetics

Selecting the right freeze dryer for cosmetics is critical for both research and commercial success. Cosmetics freeze drying equipment is generally categorized by scale, from small units for R\&D to massive systems for high-volume manufacturing. The selection of the appropriate scale is often the first and most crucial decision.

Laboratory Freeze Dryers (R&D and Testing)

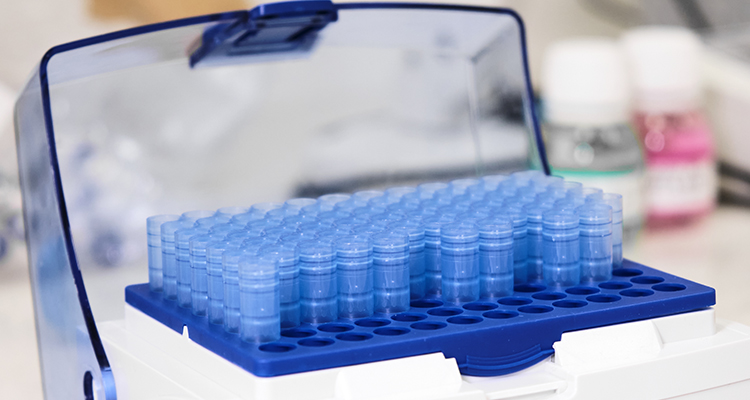

- Ideal Applications: These are small-scale freeze dryers designed for R&D, feasibility testing, formula optimization, and processing extremely high-value, low-volume batches (e.g., initial clinical samples of potent peptides).

- Features and Specifications:

- Capacity (Shelf Area): Typically <0.5 m2.

- Ice Condensing Capacity: Low, generally 2 to 6 liters per batch.

- Control System: Must offer precise, programmable control for developing optimal drying "recipes." Data logging is essential for process transfer.

- Focus: Flexibility, precise control, and quick turnaround for small samples.

- Sieno's Advantage: For laboratories, Sieno Freeze-drying Technology provides compact, sophisticated models with industry-leading control systems. These systems allow cosmetic researchers to accurately determine the optimal parameters for delicate cosmetic ingredients, ensuring the process is robust before costly scale-up begins.

Pilot-Scale Freeze Dryers (Scaling Up Production)

- Ideal Applications: Mid-sized freeze dryers for validation, process scaling up production, stability studies on commercial containers, and producing specialized batches. They bridge the gap between lab-scale testing and commercial manufacturing.

- Features and Specifications:

- Capacity (Shelf Area): Moderate, typically 0.5 to 5 m2.

- Ice Condensing Capacity: 10 to 50 liters per batch.

- Design: Often built to be movable or modular, incorporating advanced features like hydraulic stoppering for sealing vials under vacuum.

- Focus: Reproducibility, batch consistency, and regulatory compliance documentation.

- Parameter Comparison: Pilot units must demonstrate the same temperature and vacuum uniformity as the larger production units to ensure successful process transfer.

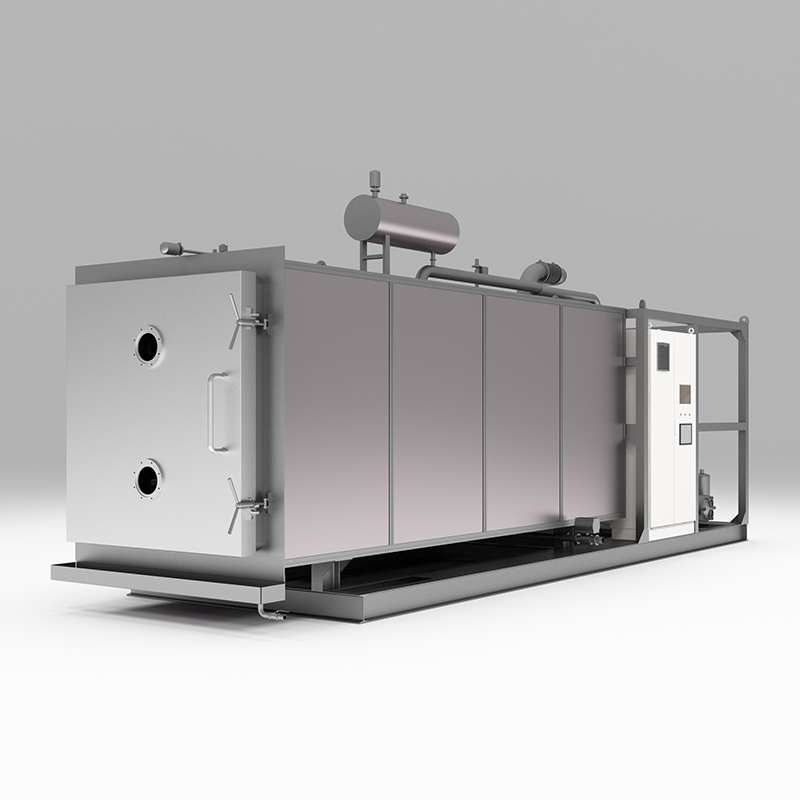

Industrial Freeze Dryers (Mass Production)

- Ideal Applications: Large-scale freeze dryers designed for mass production of freeze dried skincare and makeup, high-volume contract manufacturing, and applications requiring high throughput to reduce per-unit costs.

- Features and Specifications:

- Capacity (Shelf Area): Large, ranging from 10 m2 to over 40 m2.

- Ice Condensing Capacity: High, often 100 to 1,000+ liters per 24 hours.

- Automation: Fully automated control system with SIP/CIP (Sterilization/Cleaning In Place) capabilities to meet strict GMP requirements.

- Focus: Maximum efficiency, continuous operation, and minimal labor involvement.

| Parameter |

Laboratory Freeze Dryers |

Pilot-Scale Freeze Dryers |

Industrial Freeze Dryers |

| Typical Shelf Area |

<0.5 m2 |

0.5 to 5 m2 |

10 m2 + |

| Batch Size Focus |

Grams to Kilograms |

Kilograms to Tens of Kilograms |

Hundreds of Kilograms |

| Temperature Uniformity |

High ±1.0∘C (Critical) |

Very High ±0.5∘C (Critical) |

Excellent ±0.5∘C (Critical) |

| Automation |

Basic/Semi-Automatic |

Advanced/Recipe Management |

Full Automation and Data Recording |

| Compliance Need |

GLP/Traceability |

Validation/Documentation |

GMP/FDA Level Validation/SIP/CIP |

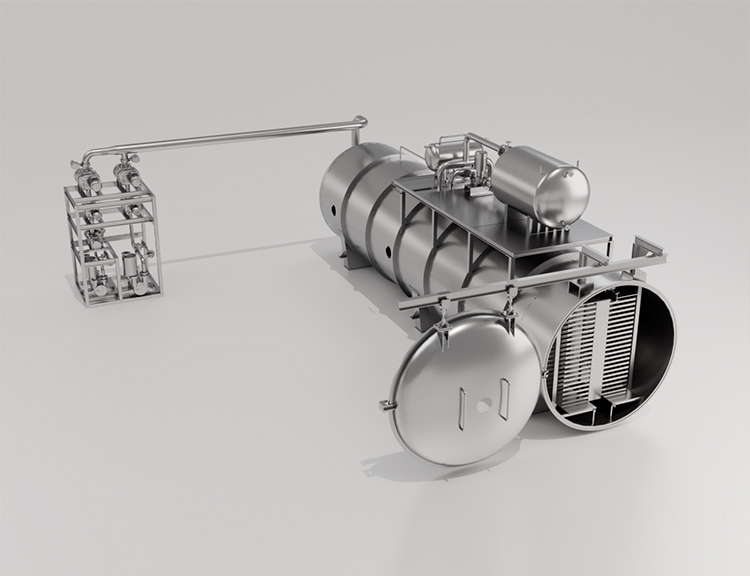

Key Components of Freeze Drying Equipment

Regardless of scale, the quality and design of the core components dictate performance. Sieno Freeze-drying Technology focuses on optimizing these components using proprietary "intelligent" technology:

Vacuum System

Essential for achieving the ultra-low pressures (e.g., 50 to 150 mTorr) required for efficient sublimation. Sieno's systems are engineered for Vacuum System Efficiency and reliability, crucial for maximizing throughput while maintaining product integrity.

Refrigeration System

Responsible for freezing the product and cooling the condenser (cold trap) to temperatures often as low as −70∘C to −85∘C to effectively capture the water vapor.

Control System

The 'brain' that orchestrates precise temperature ramps and pressure holds. Sieno's commitment to intelligent equipment manufacturing means incorporating advanced, user-friendly automation and control systems that save cycles, ensure data integrity, and minimize operator error.

Drying Chamber

The vessel where the product resides. For industrial cosmetics applications, it must be constructed from high-grade stainless steel (often 316L) and designed for easy cleaning and sterilization to prevent contamination in line with high-standard cosmetic manufacturing.

Applications of Freeze Drying in the Cosmetics Industry

The versatility of freeze drying in the cosmetics industry is continually expanding, transforming traditional liquid products into potent, stable anhydrous forms across various categories. This allows brands to meet the growing consumer demand for highly efficacious, preservative-free products.

Skincare Products (Skincare)

Freeze-dried products are particularly impactful in the skincare sector, where ingredient efficacy is paramount. Freeze drying equipment is essential for stabilizing complex, sensitive formulas.

- Freeze-dried Serums: Potent, single-use solid forms of high-concentration serums, activated instantly with water. This method preserves highly sensitive ingredients like pure Vitamin C (Vitamins), Hyaluronic Acid, and growth factors at peak potency, ensuring maximum effectiveness upon reconstitution.

- Freeze-dried Masks: Anhydrous sheet masks or powder masks that offer exceptional stability and ease of packaging. These formats are ideal for delivering large amounts of plant extracts and peptides to the skin without degradation during storage.

- Freeze-dried Ampoules: Highly concentrated, single-dose solid pellets or spheres, which are often used for stabilizing sensitive peptides or enzymes. The ability of the lyophilization process to maintain the biological activity of these compounds is a key driver for their use in high-end skincare.

Makeup Products (Makeup)

Makeup benefits from freeze drying through the preservation of color fidelity and texture consistency.

- Freeze-dried Pigments: Maintaining the brightness and true color of cosmetic pigments used in high-quality eyeshadows and pressed powders. The process ensures uniformity and excellent dispersion when applied.

- Freeze-dried Foundations: Creating lightweight, customizable powder foundations where active treatment ingredients, such as stable vitamins or mineral-based sunscreens, can be incorporated without loss of efficacy.

Hair Care Products (Hair Care)

The technique is also transforming the hair care segment, enabling highly concentrated solid formats.

- Freeze-dried Hair Masks and Treatments: Concentrated solid treatments that activate upon contact with water, ideal for preserving delicate protein structures and specialized botanical extracts or enzymes needed for potent hair repair.

Specific Cosmetic Ingredients Suited for Freeze Drying

The specialized nature of freeze drying is necessary for high-value compounds that degrade quickly when exposed to heat or water. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. leverages its deep understanding of freeze-dried food science—where nutrient retention is critical—to design intelligent freeze-drying equipment and tailored solutions that specifically protect the delicate structures of these cosmetic ingredients:

| Ingredient Entity |

Why Freeze Drying is Necessary |

Sieno's Contribution |

| Peptides |

Highly susceptible to hydrolysis (degradation in water). |

Precise temperature control to maintain the correct protein structure and biological folding. |

| Enzymes |

Activity is destroyed by heat; quickly denatured in liquid. |

Gentle, low-temperature sublimation cycles to lock in enzyme activity for maximum potency. |

| Probiotics |

Requires extreme low moisture to remain viable (dormant). |

Expert control systems ensure residual moisture is low enough to extend shelf life for live cultures. |

| Plant Extracts / Vitamins |

Potency and color often degrade due to oxidation or heat. |

Equipment designed for rapid freezing and efficient vacuum to minimize exposure time to degradative elements. |

Sieno’s comprehensive technical support, spanning from raw material processing to finished product packaging, ensures that cosmetic enterprises can safely and effectively process these fragile ingredients into highly stable, premium freeze dried cosmetics.

Factors to Consider When Choosing Cosmetics Freeze Drying Equipment

Selecting the optimal cosmetics freeze drying equipment requires a careful assessment of operational needs, technical specifications, and regulatory requirements. Making the right investment ensures product quality, efficiency, and compliance.

Capacity and Scale: Matching Equipment Size to Production Needs

The capacity of the equipment, typically measured by the total shelf area in square meters and the ice condensing capacity, must precisely align with your production strategy.

- R&D vs. Industrial: A cosmetic startup or R\&D lab only needs a small-scale unit, while a major manufacturer requires a large industrial freeze dryer to achieve economical mass production.

- Sieno's Tailored Solutions: Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. offers a range of intelligent equipment and, critically, provides tailored solutions and comprehensive technical support. This helps clients accurately calculate their throughput needs, ensuring they select the right machine size—be it a pilot-scale unit for process validation or a large system for high-volume freeze dried skincare—to avoid bottlenecks and maximize efficiency gains.

Temperature Control: Importance of Precise Temperature Regulation

Precise thermal management is the most critical factor for preserving sensitive cosmetic ingredients during the lyophilization process.

- Shelf Temperature Control: The shelves must be capable of reaching and maintaining temperatures far below freezing (e.g., −40∘C to −55∘C) during the freezing phase and then precisely increasing to optimal drying temperatures during the primary and secondary drying phases. The uniformity of the shelf temperature across the entire area (ideally within ±0.5∘C) is key to consistent product quality.

- Sieno's Intelligent Technology: Leveraging its expertise in intelligent equipment manufacturing, Sieno prioritizes advanced control systems that ensure high temperature control precision and uniformity, vital for stabilizing delicate structures like peptides and enzymes and guaranteeing cosmetic stability.

Vacuum System Efficiency: Ensuring Optimal Vacuum Levels for Sublimation

The vacuum system dictates the drying rate and, ultimately, the cycle time. It must be powerful enough to handle the large volumes of water vapor released during the primary drying phase.

- Vacuum Levels: An efficient system must rapidly and reliably achieve the deep vacuum levels (typically 50 to 150 mTorr) required for the ice to sublimate directly into vapor, bypassing the damaging liquid phase.

- Condenser Temperature: The refrigeration system's ability to maintain the condenser temperature (the cold trap) sufficiently lower than the product temperature is directly linked to Vacuum System Efficiency and overall drying speed.

Automation and Control Systems: Benefits of Automated Processes

Modern freeze dryers rely on sophisticated controls to ensure repeatability and data integrity.

- Programmability and Repeatability: Systems should allow for complex, multi-step drying "recipes" to be programmed, saved, and repeated precisely across all batches. This is non-negotiable for quality control and scaling up production.

- Data Logging: Essential for regulatory compliance, the system must log and store all critical process parameters (temperature, pressure, time) in a format suitable for quality assurance and regulatory bodies. Sieno's independently developed intelligent control systems provide the detailed data traceability necessary to meet global quality standards.

Maintenance and Service: Factors to Consider

The long-term operational cost is highly influenced by reliability and support.

- Design for Cleaning (CIP/SIP): For high-standard cosmetic manufacturing, look for features like CIP (Cleaning-In-Place) and SIP (Sterilization-In-Place), which are crucial for quick, automated sanitation and reducing the risk of cross-contamination.

- Technical Support: Consider the equipment manufacturer's commitment to long-term support. Sieno's integrated approach, driven by continuous research and strategic collaborations, ensures clients benefit from expert technical support, minimizing equipment downtime and protecting their investment.

Compliance and Certifications: GMP, FDA, and other relevant standards

Equipment used for manufacturing high-value cosmetics (especially those with therapeutic claims or high-potency actives) must adhere to rigorous standards.

- Regulatory Compliance: Ensure the equipment design, construction materials (e.g., 316L stainless steel), welding quality, and control system software (often requiring 21 CFR Part 11 compliance for electronic records) meet GMP (Good Manufacturing Practices) guidelines and any local equivalent to FDA standards required for the intended markets. Choosing a partner like Sieno helps assure that the fundamental design principles of the equipment support a client's necessary regulatory validation.

FAQ (Frequently Asked Questions)

What are the main advantages of freeze-drying cosmetics?

The main advantages of freeze drying cosmetics include the enhanced preservation of active ingredients (like potent peptides and vitamins), extended shelf life without refrigeration, and improved stability leading to reduced degradation. Crucially, the process often eliminates the need for harsh preservatives, appealing to the clean beauty market. To maximize these advantages, the equipment must offer precision. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. specializes in providing intelligent freeze-drying equipment and tailored process solutions, ensuring that cosmetic manufacturers achieve peak potency retention and the desired long-term cosmetic stability.

How does freeze drying affect the quality of cosmetic ingredients?

Freeze drying, or lyophilization, positively affects ingredient quality by preserving their native structure and biological activity. Since the process involves freezing and then removing water by sublimation under low temperature and vacuum, it entirely avoids the heat damage and chemical degradation associated with traditional liquid or heat-processed forms. This means sensitive compounds like enzymes and probiotics maintain their activity until the moment of use. Manufacturers rely on the precision of their equipment's control system to achieve this quality.

What types of cosmetic products can be freeze-dried?

A wide array of products and raw materials can be freeze-dried, focusing particularly on those with sensitive active components. This includes skincare products (such as high-concentration serums and ampoules), certain makeup products (like stable pigments), and specialized hair care products (treatments and masks). The technology is especially vital for stabilizing raw cosmetic materials like heat-sensitive plant extracts and peptides. When planning to dry new formulations, manufacturers should seek comprehensive technical guidance. Sieno Freeze-drying Technology offers comprehensive technical support covering process development from raw material handling to finished product packaging, allowing clients to confidently expand their range of freeze dried cosmetics.

How do I choose the right freeze-drying equipment for my needs?

Choosing the right freeze dryer for cosmetics depends critically on your desired scale and quality standards. You must match the equipment's capacity (shelf area) to your production volume—from a laboratory freeze dryer for R\&D to an industrial freeze dryer for mass production. Key factors to consider are precise temperature regulation ($\pm 0.5^\circ\text{C}$ shelf uniformity is ideal), robust vacuum system efficiency, and compliance features (GMP). Sieno Freeze-drying Technology leverages its core expertise in intelligent equipment manufacturing to provide reliable, scalable machines and, through strategic collaborations, offers the process expertise needed to make an informed, long-term investment decision.

What are the maintenance requirements for freeze-drying equipment?

Maintenance requirements for cosmetics freeze drying equipment involve routine cleaning and sterilization, regular checks of the refrigeration system and oil changes for the vacuum system pump, and calibration of the control system sensors. Given the high cost of production downtime, reliable long-term service is essential. To ensure longevity and maximize operational efficiency, look for a partner committed to customer service. Sieno Freeze-drying Technology Research Institute is dedicated to driving technological innovation and upgrading production, which includes offering robust aftermarket maintenance and service support, ensuring the continuous, reliable operation of your sophisticated lyophilization systems.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China