How Does the Pet Care Freeze Drying Solution Guarantee Sterilization Efficacy?

Pet food, especially Raw-Based freeze-dried products, faces a core safety challenge in controlling potential pathogens (such as Salmonella, E. coli, and Listeria). Since the freeze-drying process must occur at low temperatures to preserve nutrition and texture, traditional thermal sterilization methods (such as high-temperature extrusion) are ruled out. Therefore, professional Pet Care Freeze Drying Solutions must rely on a comprehensive system of “non-thermal sterilization” and “environmental control” technologies to ensure the microbial safety of the final product and meet the industry-required Log Reduction standards.

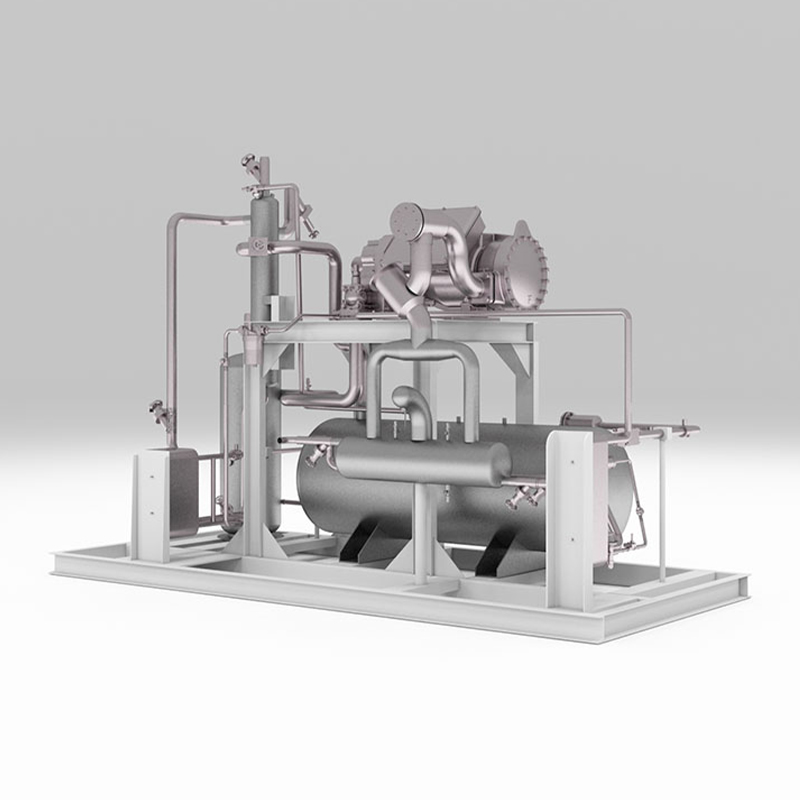

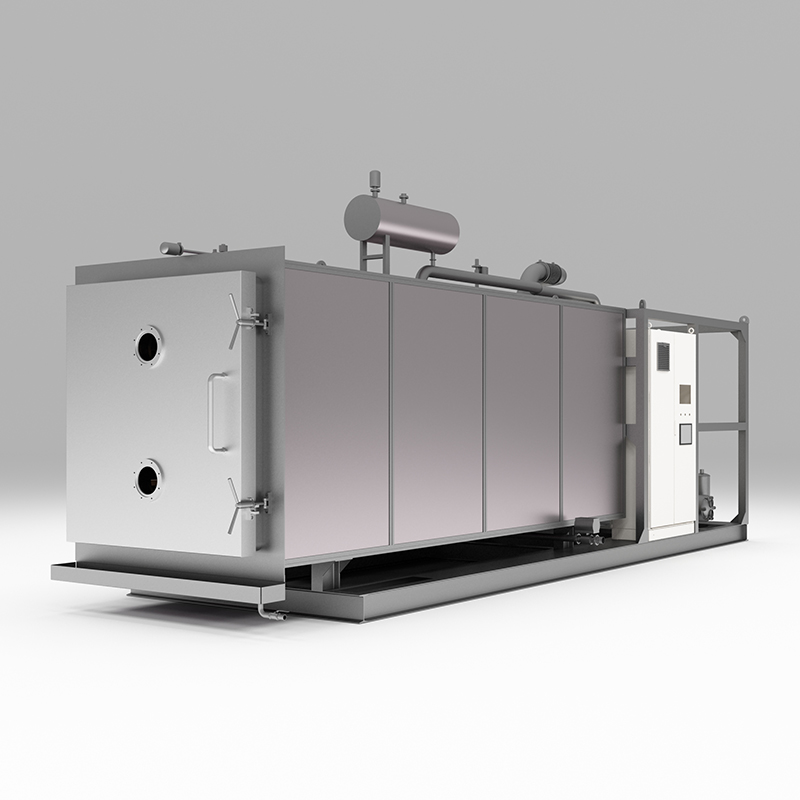

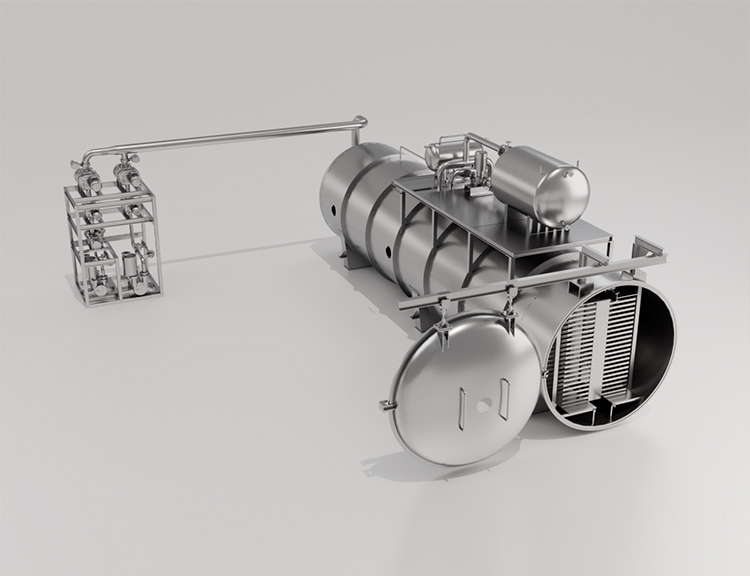

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd, leveraging its deep expertise in freeze-drying science and intelligent equipment manufacturing, offers a professional technical path to guarantee the safety of freeze-dried pet food:

I. Pre-Treatment and Environmental Control (Pre-Treatment & Environmental Control)

Ensuring sterilization efficacy begins outside the freeze-drying chamber. Sieno consistently emphasizes source control and environmental assurance:

- Raw Material Microbial Load Control: Through strategic collaborations with food science experts, Sieno guides clients in establishing strict raw material acceptance standards and pre-treatment procedures within customized solutions. This ensures that the initial microbial load (Initial Microbial Load) of the material entering the freeze-drying stage is maintained at a controllable low level, providing a foundation for subsequent freeze-drying safety.

- Clean Area Design and Cross-Contamination Prevention: Our solutions cover comprehensive technical support from raw material processing to finished product packaging. This includes assisting clients with the overall planning of the freeze-drying workshop's GMP-standard clean area. By scientific zoning, segregation of personnel and material flow, and the use of our provided automated loading and unloading systems, we maximize the reduction of manual intervention and secondary contamination introduced by the environment.

II. The “Cold Chain Kill Mechanism” during the Freeze-Drying Process

Although freeze-drying does not use high heat, the specific process parameters—low temperature and high vacuum environment—inherently possess a powerful inhibitory and inactivation effect on microorganisms.

- Mechanical Damage from Ice Crystals: During the pre-freezing stage, the precise control of the cooling rate by our autonomously developed intelligent freeze-drying equipment results in the formation of fine, uniform ice crystals, which exert mechanical stress damage on the cell walls and internal structures of microorganisms. While this does not equate to complete sterilization, it significantly weakens microbial vitality.

- Vacuum Dehydration Stress: The sublimation drying stage is conducted under an extremely high vacuum. Water transitions directly from solid ice to vapor, causing microbial cells to lose water and enter a state of severe dehydration. This extreme reduction in Water Activity and the vacuum stress environment effectively inhibits the metabolic activity of most pathogens, leading to their death or permanent inactivation. Sieno’s intelligent system can precisely control and maintain the optimal vacuum degree and shelf temperature, ensuring thorough dehydration, with a final product moisture content far below the microbial survival threshold (typically less than 5%).

III. Core Technology for Log Reduction: Integration of E-Beam or High-Pressure Processing

To ensure the product meets international and domestic pet food safety standards (often requiring a Log Reduction of 5Log units, meaning the destruction of 99.999% of pathogens), Sieno’s customized solutions can integrate or be compatible with advanced non-thermal sterilization technologies based on client needs:

- Electronic Beam (E-Beam) or Gamma Irradiation Technology:

- As a post-processing technology, Sieno's equipment design fully considers the seamless connection with subsequent sterilization stages. E-Beam technology utilizes high-energy electron beams to destroy the DNA structure of microorganisms through ionization radiation. It achieves highly efficient and thorough sterilization without significantly raising the product temperature, making it one of the most reliable commercial sterilization methods for raw freeze-dried pet food.

- Our solutions guide clients in determining the optimal irradiation dose to guarantee sterilization efficacy while preserving the product's sensory characteristics and nutritional value.

- Integration of High-Pressure Processing (HPP) (HPP Pre-treatment):

- Some clients may choose to subject raw meat to HPP before freeze-drying. This technology uses ultra-high water pressure to kill pathogens.

- Sieno's customized solutions ensure that HPP-treated products are perfectly matched with the freeze-drying process, for example, by optimizing the pre-freezing speed to prevent changes in tissue structure after high-pressure treatment from affecting drying efficiency.

How Does the Pet Care Freeze Drying Solution Flexibly Adapt to the Freeze-Drying Needs of Different Forms of Pet Food Raw Materials?

The current pet food market's demand for product form innovation is growing, ranging from traditional freeze-dried meat chunks and pellets to functional freeze-dried mixed meals, puréed treats, and powder or granular products rich in probiotics. The complexity of raw material forms places extremely high flexibility requirements on freeze-drying equipment and processes.

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd is dedicated to the deep integration of freeze-drying food science and intelligent equipment manufacturing. Our core competence lies in providing highly customized and modular freeze-drying solutions with superior process design and intelligent equipment to ensure optimal freeze-drying results for all types of pet food forms.

I. Professional Analysis of Raw Material Forms and Freeze-Drying Challenges

We categorize pet food freeze-drying needs based on raw material form and address their specific technical challenges:

- High Solid/Large Meat Chunk Forms (e.g., freeze-dried chicken breast chunks, beef pellets):

- Challenge: Long sublimation path, extended drying time, potential for Case Hardening (hard exterior, moist interior).

- Sieno Solution: Our customized solution focuses on precise pre-freezing, ensuring small, uniform ice crystals; and utilizes a strategy of low pressure and high temperature (but below eutectic/collapse temperature) during the sublimation stage to optimize heat transfer efficiency, shorten the drying time, and ensure thorough internal water sublimation, resulting in a uniform structure and high crispness in the final product.

- Purée/Paste/Liquid Forms (e.g., nutritional pastes, mixed purée main meals):

- Challenge: Susceptible to collapse, splashing, high variability in product solid content and viscosity, making it difficult to maintain a stable form.

- Sieno Solution: The solution involves front-end forming technology and customized freeze-drying trays. We collaborate with clients to develop specialized molds or forming mechanisms to ensure that puréed materials form standard, consistent shapes before pre-freezing. Simultaneously, we leverage the plate uniformity and ultra-low temperature pre-freezing capability of the vacuum freeze-drying chamber for rapid solidification, preventing form destruction during vacuum start-up.

- Granular/Powder Forms (e.g., probiotic powder, mixed nutrient granules):

- Challenge: High bulk density, limited sublimation, prone to localized overheating, leading to the inactivation of active substances.

- Sieno Solution: Focuses on thin, uniform layer spreading and precise temperature curve control. Our intelligent equipment utilizes PLC to precisely control minute variations in shelf temperature to achieve low-temperature, slow desorption drying. For extremely heat-sensitive probiotics, we combine our collaboration with academic institutions to provide specific cryoprotectant addition protocols and optimized freeze-drying curves to ensure a high microbial survival rate.

II. The "Flexibility" Design of Intelligent Freeze-Drying Equipment

Sieno’s independently developed intelligent freeze-drying equipment provides the hardware foundation and control core for adaptability:

- Customized Trays and Loading Systems:

- We offer multiple materials and structures of customized trays to meet the loading needs of different material forms, such as deep-sided trays for liquid/puréed materials and perforated trays for meat chunks.

- Our automated loading and unloading systems are designed with a high degree of compatibility, allowing for quick switching and adaptation to different tray sizes and structures, significantly increasing the production line's flexibility and changeover efficiency.

- Multi-Stage Temperature and Pressure Control Capability:

- Sieno’s intelligent control system allows operators to perform multi-stage, high-precision programming of the freeze-drying process. This means we can establish a “dedicated freeze-drying recipe” for different material forms. For instance, high-fat meat chunks require a longer secondary drying time, while fruit and vegetable mixtures with higher sugar content need lower pre-freezing and sublimation temperatures to prevent collapse.

- Advanced Online Monitoring Technology:

- Using advanced temperature, pressure, and vacuum sensors, our equipment can monitor key process data in real time. Combining our collaboration with academic institutions, we have introduced the principle of online eutectic point/collapse temperature evaluation, ensuring that no matter what formulation the client switches to, the system can provide warnings and optimization suggestions, preventing costly batch loss.

III. The Value of Sieno's Full-Process Technical Support

The value of Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd lies not only in selling equipment but also in providing comprehensive technical support from “raw material to finished product packaging”:

- Synergistic Formulation and Process Development: We collaborate with clients on raw material science, helping them adjust their pet food formulations (e.g., optimizing cryoprotectant ratios, adjusting pre-treatment moisture content) based on the freeze-drying process to ensure their formula achieves optimal results in the freeze dryer.

- Balancing Efficiency and Quality: Our customized solutions are dedicated to empowering clients to achieve efficiency gains and quality upgrades while adapting to diverse forms. Whether the product is a crunchy treat or a rapidly rehydrating raw meal, Sieno can provide stable, efficient, and traceable freeze-drying production solutions through process optimization.

In summary, Sieno, through its deep expertise in freeze-drying science and intelligent equipment manufacturing capability, offers pet food manufacturers exceptional process flexibility and technical assurance to confidently meet the market’s ongoing demand for diverse pet food forms.

What are the Advantages and Challenges of Multi-Stage Freeze-Drying Technology in the Pet Care Freeze Drying Solution?

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd focuses on the profound integration of freeze-drying science with intelligent equipment manufacturing. The Multi-Stage Freeze Drying Technology is a crucial process strategy in our intelligent freeze-drying equipment and customized solutions for enhancing the quality, efficiency, and energy savings of pet food.

Q1: What is Multi-Stage Freeze-Drying Technology in Pet Food, and how does it differ from traditional freeze-drying?

A: Traditional freeze-drying (or single-stage freeze-drying) usually treats primary drying (sublimation) and secondary drying (desorption) as a continuous process, with relatively steady adjustments to shelf temperature and vacuum pressure at different stages.

Multi-Stage Freeze-Drying Technology is a more refined and dynamic process strategy. It divides the drying process into multiple sub-stages based on the changes in the material's ice-layer interface position, moisture binding state, and material temperature. In each sub-stage, we utilize the intelligent control system independently developed by Sieno to implement precise, non-linear programming and control of the shelf temperature (Tp) and chamber pressure (Pc). This maximizes heat transfer efficiency while strictly preventing collapse (Collapse) or melt-back (Melt-back) of the material.

Q2: What are the main advantages of Multi-Stage Freeze-Drying Technology in Pet Care Freeze Drying Solutions?

A: Multi-stage freeze-drying technology offers multiple core advantages for pet food manufacturers, which is central to Sieno's ability to empower clients for efficiency gains and quality upgrades:

- Significantly Shortened Drying Cycle (Efficiency Improvement):

- In the early stages of sublimation, the material has high free water content and low sublimation resistance. Multi-stage technology allows for setting higher permissible shelf temperatures to maximize the sublimation rate with high heat input, without touching the eutectic point/collapse temperature.

- As drying progresses and material resistance increases, the Sieno intelligent system dynamically adjusts parameters to optimize heat transfer in the later stages. Overall, this can shorten the drying cycle by 15\% to 30\%, significantly increasing the factory's batch throughput and capacity.

- Guaranteed Product Quality and Integrity (Quality Upgrade):

- Preventing Collapse: For complex pet compound formulas containing sugar or high-fat content (e.g., meat chunks mixed with fruits/vegetables), which have a lower collapse temperature (Tc), multi-stage control allows for more precise temperature management during sublimation. This ensures the material temperature always stays within the safe temperature window, thereby preserving the porous structure of the freeze-dried product and ensuring ideal rehydration properties and a crispy texture.

- Maximized Nutrient Retention: Precise control of the secondary drying stage (desorption drying) ensures that residual moisture is minimized (typically below 5\%) while avoiding high-temperature degradation of proteins and heat-sensitive vitamins, guaranteeing the nutritional value of the pet food.

- Optimized Energy Consumption (Sustainability):

- By precisely controlling heat input, we avoid unnecessary prolonged low-temperature operation, increasing the utilization efficiency of the refrigeration and heating systems. This aligns with Sieno's commitment to enabling clients to achieve environmental sustainability.

Q3: What are the professional challenges in implementing Multi-Stage Freeze-Drying Technology, and how does Sieno address them?

A: Despite its significant advantages, implementing multi-stage freeze-drying requires extremely high equipment precision and a deep understanding of the process:

- Challenge 1: Precise Determination and Real-Time Control of Critical Temperatures

- Challenge: Pet food raw materials (e.g., raw meat, organs, mixed ingredients) have complex formulas, making it difficult to define a uniform eutectic point or collapse temperature. Parameter errors can lead to batch loss.

- Sieno Response: We utilize the results of our strategic collaborations with experts and professors from Chinese universities and food science schools to provide clients with testing and analysis of material critical temperatures. More importantly, our intelligent freeze-drying equipment is equipped with advanced sensors and PLC control logic to achieve “closed-loop control” of the freeze-drying curve, ensuring that the material temperature consistently fluctuates within the safety zone as shelf temperature and chamber pressure change.

- Challenge 2: Programming and Management of Complex Programs

- Challenge: Compared to the simple programs of traditional freeze-drying, multi-stage process programs are complex and require higher professional skills from operators.

- Sieno Response: Our intelligent freeze-drying equipment provides an intuitive SCADA/human-machine interface with a built-in library of optimized “freeze-drying recipes” for different pet food forms (e.g., pure meat, compound, high-fat). Clients can directly call and fine-tune these validated programs, greatly reducing operational difficulty and the risk of human error.

- Challenge 3: Maintaining Batch-to-Batch Consistency

- Challenge: The larger the production scale, the greater the difficulty in ensuring that every tray and every batch strictly follows the multi-stage curve to achieve consistent final moisture content and texture.

- Sieno Response: Our high-precision temperature-controlled shelf design ensures the uniformity of heat transfer within the freeze-drying chamber. Combined with a comprehensive data acquisition and traceability system, real-time comparison of multi-stage process parameters against the preset curve is possible, ensuring the quality consistency of every batch of pet food, fully meeting clients' requirements for product stability.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China