How Is Pharmaceutical Freeze-Drying Equipment Designed to Ensure Operator Safety and Containment for High-Potency and Highly Toxic Drugs?

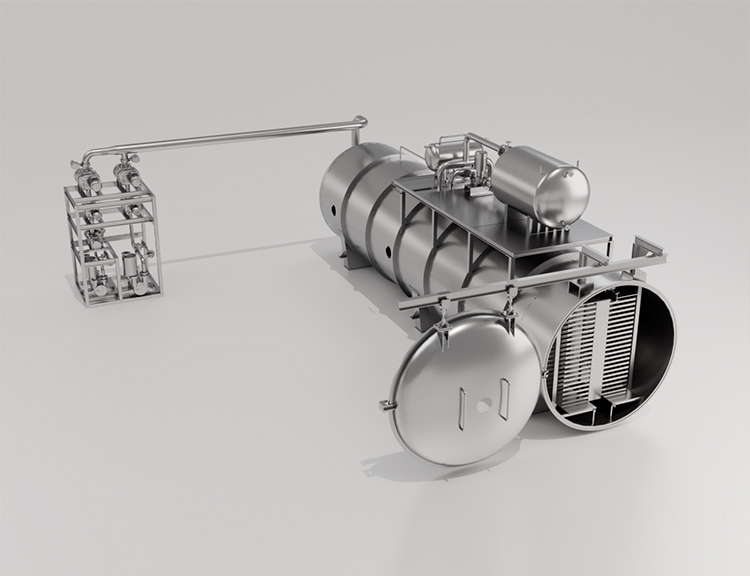

In modern pharmaceutical manufacturing, particularly for the production of innovative and highly sensitizing drugs (such as certain cytotoxic drugs, high-potency peptides, or biologics), operator safety and drug product containment are two core elements in freeze-drying equipment design. As a manufacturer specializing in intelligent freeze-drying equipment and customized solutions, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd understands the zero-tolerance attitude towards risk in the pharmaceutical and healthcare sector. Our design philosophy and technological practices are built upon the highest standards for containment control and safety assurance.

I. Design and Classification of Containment Levels

The primary task for freeze-drying systems handling High-Potency Active Pharmaceutical Ingredients (HPAPI) is to achieve multi-level containment protection to prevent drug dust or aerosols from escaping into the operating environment. Containment levels are typically classified based on the Occupational Exposure Limit (OEL).

Sieno's customized solutions can design systems ranging from Primary Containment to High Containment (OEB Level 4/5) based on client OEL requirements:

- Physical Barrier Design: The freeze dryer’s main chamber is the first containment barrier. For highly toxic substances, we utilize Isolators or Restricted Access Barrier Systems (RABS) to completely separate the freeze dryer from the cleanroom environment. The isolator maintains a negative pressure inside, ensuring any potential leakage is contained within the isolator.

- “Dust-Free” Loading/Unloading Systems: The loading and unloading of the drug product upon entering and exiting the lyophilizer chamber represent the highest-risk points. We minimize human intervention and achieve contained material transfer by integrating Automated Loading/Unloading Systems, Glove Ports, and Continuous Liner Technology.

II. Containment and Safety Design of Key Components

The successful implementation of containment relies on the synergistic design and technical assurance of every equipment component.

1. Contained Interfaces for Dosing and Discharge

- Alpha/Beta Split-Valve System (A/B Split-Valve): This is a standard configuration in high-containment systems. Sieno employs high-quality A/B valves in freeze-dryer design to ensure zero dust leakage when transferring vials, trays, or intermediate containers into and out of the isolator or main chamber.

- Contained Cleaning and Transfer: Contained unloading post-lyophilization connects to a Contained Transfer Cart to ensure the product remains under controlled, contained conditions while being moved to the capping or secondary packaging area.

2. Triple Protection for Vacuum and Exhaust Systems

Vapor generated during the sublimation process must be thoroughly treated before being exhausted.

- Condenser Design: The condenser effectively traps water vapor at low temperatures, but for high-potency substances, drug residue may adhere to it. Our design ensures the condenser is fully capable of Clean-in-Place and Steam-in-Place (CIP/SIP).

- Exhaust Filtration System: The exhaust port of the vacuum pump must be equipped with multi-stage filtration. Sieno uses cascaded HEPA/ULPA Filters (H13/H14 grade) with an efficiency exceeding 99.999%, effectively trapping sub-micron aerosols that may be carried out with the gas. Furthermore, for specific toxic substances, the exhaust system may require a pre-treatment stage with an Activated Carbon Adsorption Tower or a Wet Scrubber.

- Vacuum Pump Isolation and Protection: The vacuum pump is a potential leakage point. We house the vacuum pump in a separate, contained exhaust enclosure and utilize oil-free or dry vacuum pumps to prevent oil mist contamination of the environment.

3. Chamber Clean-in-Place and Steam-in-Place (CIP/SIP)

This is a critical step for eliminating cross-contamination and ensuring operator safety.

- Comprehensive Spray Coverage: Sieno’s freeze-drying chamber and condenser interiors are designed with optimized spray balls and nozzles to ensure all internal surfaces, including shelf bottoms and vacuum lines, are thoroughly covered by cleaning solution and steam.

- Closed-Loop Disposal: The cleaning liquid (containing active drug residue) is treated as contaminated material and must be collected and transferred via a closed-loop system to a dedicated Waste Liquid Tank, preventing direct operator contact.

- SIP Validation: The steam sterilization process undergoes rigorous Heat Mapping verification using multi-point temperature probes and heat penetration tests to ensure the chamber interior reaches and maintains the required sterilization temperature and duration.

III. Intelligence and Continuous Monitoring

Based on the deep accumulation of intelligent equipment manufacturing and freeze-drying science at Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd, we integrate advanced monitoring and control features into our HPAPI freeze-drying equipment:

- Negative Pressure and Leak Monitoring: The isolator or contained chamber continuously monitors the internal negative pressure value, should pressure become abnormal, the system immediately alarms and initiates an auxiliary safety ventilation mode.

- Process Data Recording and Audit Trail: All pressure, temperature, and flow data comply with FDA 21 CFR Part 11 requirements, guaranteeing Data Integrity and traceability as evidence of safety compliance.

- Personnel Protection and Training Integration: Although the equipment is highly contained, we emphasize ergonomic design to ensure maintenance and intervention points are easily accessible, coupled with mandatory Interlocks to prevent operations under hazardous conditions.

In summary, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd’s approach to designing freeze-drying equipment for high-potency and highly toxic drugs is not merely about providing a machine, but delivering an integrated, validated containment solution. We control risks at the source, safeguard operator health, and ensure the purity and safety of the drug product by integrating isolation technology, A/B valves, efficient exhaust filtration, and comprehensive CIP/SIP systems.

In modern pharmaceutical R&D, drug formulations are becoming increasingly complex to improve the bioavailability of poorly soluble drugs or maintain the activity of biologics. Formulations containing Organic Solvents in mixed solvent systems, and those with Low Eutectic Temperature or Glass Transition Temperature due to the properties of active ingredients or excipients, pose severe challenges to conventional freeze-drying equipment and processes.

As a pioneer specializing in intelligent freeze-drying equipment and customized solutions, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd is dedicated to integrating deep freeze-drying science with intelligent equipment manufacturing. Although we initially focused on food freeze-drying science and technological upgrades, our core expertise in precise temperature control, efficient vacuum management, and process customization provides a solid foundation for tackling complex drug lyophilization challenges in the healthcare sector.

I. Challenges and Solutions for Low Eutectic/Glass Transition Temperatures

Many complex drug formulations, such as salt-containing, acidic, or amorphous structure-dominated biologics, may have extremely low critical freezing temperatures, potentially below −40∘C. This necessitates the primary drying process be carried out under extremely rigorous conditions.

1. Superior Ultra-Low Temperature Control Capability

- Ultra-Low Temperature Refrigeration System: Sieno’s customized freeze-drying equipment employs multi-stage cascade or mechanically-assisted refrigeration systems to ensure shelf temperatures can be accurately and stably lowered to −60∘C or even lower. This far exceeds the requirements for conventional water-based formulations, ensuring freezing and primary drying are completed at extremely low temperatures.

- Shelf Temperature Uniformity: Near the critical temperature, any temperature fluctuation across the shelf can lead to product Collapse or Melt-back. Our intelligent equipment ensures shelf temperature uniformity of ≤±1.0∘C through optimized heat transfer fluid circuit design and high-precision PID control algorithms, thereby ensuring batch-to-batch product consistency.

2. Precise Lyophilization Cycle Optimization

- Temperature Monitoring and PAT Integration: We advocate the use of Process Analytical Technology (PAT) such as Resistance Measurement, Capacitance, or wired/wireless temperature probes to monitor product temperature in real-time, especially near the sublimation interface.

- Controlled Nucleation Technology: Controlled Nucleation technology is crucial for amorphous or glassy systems. By precisely controlling pressure during the freezing phase to induce ice crystals to nucleate at nearly the same temperature across all vials, we ensure crystal size uniformity, shorten primary drying time, and enhance the appearance and stability of the lyophilized cake.

II. Safe and Efficient Handling of Organic Solvent Formulations

When processing systems containing organic solvents such as tert-butanol, acetonitrile, or methanol during freeze-drying, two major challenges arise: the low freezing point of the solvent and potential flammability/toxicity.

1. Solvent Compatibility and Explosion-Proof Design

- Equipment Material Compatibility: Organic solvents can corrode standard seals and vacuum pump oil. Sieno selects chemically resistant Teflon (PTFE) or specialized elastomer materials for solvent-contacting components (e.g., seals, valves, vacuum lines).

- Explosion-Proof Safety Configuration (ATEX/NEC): For flammable organic solvents, our freeze-drying systems can provide customized designs compliant with ATEX or NEC explosion-proof standards. This includes using explosion-proof motors, sensors, and electrical components, and installing Inert Gas Purging systems near the vacuum pump, condenser, and exhaust ports to eliminate fire or explosion risks.

2. Organic Solvent Efficient Trapping and Disposal

- Ultra-Low Temperature Condenser Design: The vapor pressure of many organic solvents is higher than that of water. To trap them efficiently, the condenser temperature must be significantly lower than the solvent’s freezing point. Our customized solutions can provide ultra-low temperature condensers (e.g., −80∘C or lower) to ensure rapid condensation/sublimation of organic solvent vapors.

- Dual-Stage Condenser System: For mixed solvent systems, a cascaded Dual-Stage Condenser can be used: the first stage traps the majority of water, and the second stage is designed for a lower temperature to efficiently trap organic solvents, protecting the vacuum pump and optimizing trapping efficiency.

- Solvent Recovery and Disposal: The trapped organic solvents must be safely and compliantly recovered or disposed of. Sieno’s systems can be configured with contained solvent collection tanks and use Nitrogen Purge to safely transfer the collected solvent to the waste disposal system.

Through this meticulous handling of temperature, vacuum, safety, and material compatibility, Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd extends the advantages of our Intelligent Freeze-Drying Equipment to the most complex pharmaceutical applications, offering clients customized lyophilization solutions that combine safety, high efficiency, and superior product quality.

Regarding Different Biologics, How Does Pharmaceuticals & Healthcare Freeze-Drying Equipment Optimize Excipient Selection and Pre-treatment Steps?

Biological products, such as vaccines, monoclonal antibodies (mAbs), and cell and gene therapy products, demand extremely high stability from the freeze-drying process due to their complex and fragile molecular structures. The selection of excipients and the precision of pre-treatment steps are crucial for ensuring biological activity and achieving long-term shelf life success.

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd is committed to integrating deep freeze-drying science with intelligent equipment manufacturing. Leveraging our strategic collaborations with experts and professors from Chinese universities and food science schools, we are able to extend the high-efficiency, precision, and controllability principles of food lyophilization to the most demanding healthcare applications, offering customized freeze-drying solutions for various biologics.

Q1: What are the core principles for excipient selection across different biologics, and how does Sieno’s intelligent equipment support this selection?

Professional Answer:

Excipients play three core roles in the lyophilization of biologics: Protectants/Stabilizers, Bulking Agents, and Buffering Agents. The core principle is "tailor-made with minimal intervention."

| Type of Biologic |

Primary Stability Challenge |

Recommended Excipient Type |

Key Functions Supported by Sieno Equipment |

| Proteins/Antibodies |

Denaturation, Aggregation, Oxidation |

Sugars (Trehalose, Sucrose): Act as protectants, forming a glassy matrix to stabilize secondary/tertiary structures. |

- High-Precision Temp Control: Ensures accurate freezing rates for maximum stable glass formation.

- PAT Integration: Real-time monitoring of Glass Transition Temperature to prevent primary drying collapse.

|

| Vaccines/Viral Vectors |

Loss of surface activity, particle integrity |

Polymers (Polysorbate): Act as surfactants to reduce adsorption and shear stress damage. Amino Acids (Glycine): Aid in stabilization. |

Pre-treatment Uniformity: Automated filling systems ensure homogeneous formulation mixing, avoiding concentration gradients. |

| Live Cells/Strains |

Cell membrane damage, rapid water loss |

Polyols (Glycerol): Act as osmotic protectants. Proteins (Serum Albumin): Provide nutritional and physical support. |

Slow, Controlled Cooling: Utilizing intelligent freeze dryers to precisely control the freezing rate (e.g., 1∘C/min) to minimize ice crystal damage and ensure cell viability. |

Sieno's Intelligent Freeze-Drying Equipment can quickly adapt to these diverse excipient needs through its flexible recipe storage and parameter adjustment system. Our independently developed intelligent control system allows users to conduct Design of Experiments to rapidly determine the Critical Freezing Temperature and optimal lyophilization cycle for different excipient ratios.

Q2: How Is the "Pre-treatment Step" Optimized to Enhance Freeze-Drying Efficiency and Biologic Stability? What Are Sieno’s Equipment Advantages in This Process?

Professional Answer:

The pre-treatment steps mainly include Accurate Formulation, Aseptic Filling, and the Critical Primary Freezing process. Freezing is the most determinant factor for final product quality.

1. Accurate Formulation and Filling

- High-Precision Filling: Ensures high consistency in the liquid volume of each vial, which is fundamental for subsequent lyophilization uniformity. Sieno's customized solutions can integrate high-precision peristaltic pump or piston pump filling systems to ensure minimal volume deviation across batches.

- Dissolved Oxygen Control: Many biologics are susceptible to oxidation. Our system can enhance product stability by reducing dissolved oxygen in the formulation through Inert Gas (e.g., Nitrogen) Purging before filling and freezing.

2. Freezing Strategy Optimization: Application of Controlled Nucleation Technology

Traditional freezing is often random, leading to varying ice crystal nucleation temperatures among vials. This results in different ice crystal sizes, ultimately affecting sublimation rates and product uniformity.

Sieno’s core advantage in intelligent freeze-drying equipment lies in the precise control of the freezing stage, particularly the application of Controlled Nucleation technology:

- Technical Principle: After cooling the shelves to the target temperature, a small amount of inert gas is introduced, and the pressure is rapidly reduced to induce supercooled liquid to nucleate almost simultaneously and at the same temperature.

- Equipment Implementation: Our intelligent equipment is equipped with high-sensitivity pressure control valves and precision temperature sensors, capable of controlling chamber pressure during nucleation with extreme accuracy, ensuring nucleation uniformity of ≤±0.5∘C.

- Advantage Realization:

- Improved Uniformity: Avoids excessive variation in freeze-drying time between different vials.

- Reduced Cycle Time: A uniform ice crystal structure (fewer irregular crystals) facilitates water sublimation, potentially reducing primary drying time by 10% to 20%.

- Enhanced Appearance: Eliminates the irregular cake shape resulting from random nucleation, improving the final product's appearance.

Q3: How Is Sieno's Intelligent Platform Utilized to Scale Up Excipient and Pre-treatment Parameters?

Professional Answer:

The core value of Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd lies in our Intelligent Freeze-Drying Equipment and Customized Solutions, which enable seamless transition from R&D to large-scale production.

- Scientific Data-Driven Scale-up: We do not rely on empirical scale-up. By utilizing tools like the Freeze-Drying Microscope and Differential Scanning Calorimetry (DSC) on laboratory equipment, combined with heat flow information collected by our equipment's PAT system, we accurately determine the formulation’s Critical Temperature and mass transfer resistance.

- Geometric Similarity and Heat Transfer Modeling: Sieno's pilot and production-scale freeze dryers are strictly designed to maintain geometric similarity and heat transfer characteristics between shelves. This means that key process parameters like shelf temperature and vacuum degree are comparable from lab to production line, greatly mitigating scale-up risks.

- Application of Intelligent Control Algorithms: Our intelligent platform incorporates freeze-drying kinetic models. Clients can input the excipient type, initial concentration, and target residual moisture content. The system then automatically generates optimized primary and secondary drying parameters based on the pre-set material characteristic model, ensuring the optimal glassy state of the excipient and the highest possible activity retention rate of the biologic.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China