What precautions should be taken when using research freeze drying equipment?

Understanding the Nature of Research Freeze Drying Equipment

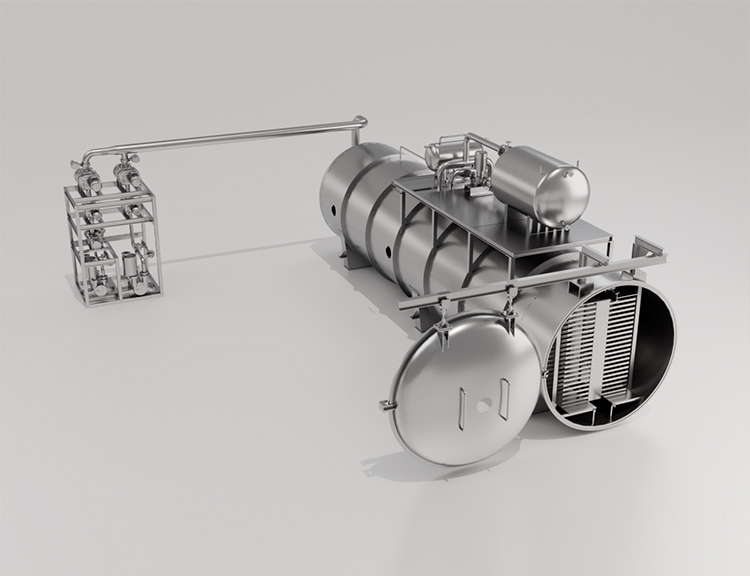

Research freeze drying equipment, also known as lyophilizers, is used to remove water or solvents from sensitive samples through sublimation. This process is critical in fields such as pharmaceuticals, biological research, food science, and material analysis. Since the samples are often delicate, and the machinery involves low temperatures, vacuum systems, and precise controls, careful precautions are necessary to ensure operational safety, equipment longevity, and reliable results. Researchers should familiarize themselves with the unique operational requirements and potential risks before use.

Proper Installation and Setup

One of the first precautions in using freeze drying equipment is ensuring correct installation. The equipment should be placed on a stable, level surface to prevent vibration, which may interfere with sample stability and the vacuum system. Adequate ventilation must be ensured, as the machinery generates heat during operation. Electrical connections must match the manufacturer’s recommendations, and grounding should always be verified. Improper setup may lead to equipment malfunction, inaccurate drying cycles, or safety hazards for users working near the system.

Sample Preparation Precautions

Sample preparation is a key factor in ensuring the effectiveness of freeze drying. Samples should be pre-frozen properly before being loaded into the equipment, as incomplete freezing can lead to uneven sublimation and structural damage. The use of containers or vials that are compatible with vacuum and low-temperature conditions is recommended to avoid cracks or leaks. Overloading the equipment should be avoided, as excessive volume can reduce efficiency, extend drying cycles, and place strain on the vacuum pump and refrigeration system.

Monitoring Temperature and Vacuum Conditions

The freeze drying process requires careful control of temperature and vacuum. Deviations from the specified range can compromise both the sample and the equipment. Regular monitoring of the condenser temperature is important to ensure that water vapor or solvents are effectively trapped. Similarly, the vacuum pressure should be maintained at the level recommended for the sample type. Pressure that is too low or too high can lead to inefficient drying or even equipment damage. Automated monitoring systems can help, but manual checks are also recommended for added safety.

Handling of Solvent-Based Samples

Some research freeze drying applications involve solvents such as ethanol, acetonitrile, or other organic chemicals. These solvents present additional hazards because they can be flammable, corrosive, or damaging to vacuum pumps. When handling solvent-based samples, it is necessary to use traps and filters that prevent vapor from reaching the pump. Proper ventilation is essential to reduce the risk of solvent vapor accumulation in the laboratory. Users must also ensure that compatible materials are used within the chamber to withstand solvent exposure.

Key Parameters to Monitor During Freeze Drying

| Parameter |

Importance |

Precaution |

| Condenser Temperature |

Ensures vapor capture |

Keep below freezing point of solvent |

| Vacuum Pressure |

Controls sublimation efficiency |

Maintain within recommended range |

| Sample Temperature |

Protects sample integrity |

Avoid overheating during drying |

| Loading Volume |

Prevents system overload |

Do not exceed manufacturer’s guidelines |

Maintenance of the Vacuum Pump

The vacuum pump is one of the most important components of freeze drying equipment. To maintain performance, oil-based pumps must be regularly checked for oil quality and replaced when contaminated. Contaminants such as water or solvents in the oil can damage the pump and reduce efficiency. Oil-free pumps also require inspection for wear, seals, and filter replacement. Ensuring that traps and filters are installed before the pump can reduce the risk of vapor damage. Neglecting pump maintenance often leads to costly repairs and inconsistent drying results.

Cleaning and Sterilization Procedures

Freeze drying equipment must be cleaned regularly to prevent contamination of samples. Residues from biological or chemical samples can accumulate on shelves, chambers, and condensers. Cleaning should be done with materials compatible with the equipment, and care must be taken not to scratch or corrode sensitive surfaces. For biological applications, sterilization may be required to prevent cross-contamination. Using alcohol-based disinfectants or manufacturer-recommended cleaning solutions can maintain hygiene while preserving the integrity of the machine.

Safety Precautions in Handling Frozen Samples

Since freeze drying involves extremely low temperatures, users must exercise caution when handling frozen samples. Protective gloves should be worn to prevent frostbite, and vials or containers should be handled carefully to avoid cracking. Rapid changes in temperature should be avoided, as they can lead to structural damage of the sample. It is also important to minimize exposure of samples to room humidity, which can condense and interfere with the freeze drying process. Following proper safety guidelines ensures both user safety and sample quality.

Electrical and Mechanical Safety

Freeze drying equipment relies on a combination of electrical systems and mechanical parts, including compressors and motors. Regular inspection of wiring, plugs, and insulation is necessary to prevent electrical hazards. Mechanical components such as fans and compressors should be kept clean and free from obstructions. Safety interlocks, which prevent the chamber from being opened under vacuum, should never be bypassed. These systems are designed to protect both the operator and the equipment from damage during operation.

Common Maintenance Activities and Frequency

| Maintenance Activity |

Frequency |

Purpose |

| Vacuum Pump Oil Change |

Every 500–1000 hours |

Prevents contamination and wear |

| Filter Replacement |

Every 3–6 months |

Protects pump and chamber |

| Condenser Cleaning |

After each run |

Removes residual moisture or solvent |

| System Calibration |

Annually |

Ensures accurate temperature and pressure readings |

Precautions for Long-Term Storage of Equipment

When freeze drying equipment is not in use for extended periods, precautions should be taken to protect it. The chamber should be cleaned and dried thoroughly to avoid mold or corrosion. Vacuum pumps should be stored with clean oil or properly sealed. Electrical components must be protected from dust and moisture. Covering the equipment with a dust-resistant cover can prolong its lifespan. Restarting after long storage should be done gradually, with checks on all systems to confirm operational readiness.

Training and User Competence

Another precaution relates to the competence of personnel operating the equipment. Freeze drying involves a combination of thermal, vacuum, and mechanical processes that require knowledge of scientific principles as well as equipment operation. Training sessions should include both theoretical background and hands-on practice. Operators should understand how to respond to unexpected pressure fluctuations, temperature deviations, or alarms. A well-trained user reduces the likelihood of accidents, sample loss, or equipment damage.

Data Monitoring and Documentation

Accurate documentation is important for research conducted with freeze drying equipment. Recording vacuum levels, condenser temperatures, sample weights, and drying times provides data that can be used for troubleshooting and optimizing future runs. Many modern systems include digital monitoring, but manual notes are still valuable for validation and compliance. Keeping a detailed log of maintenance activities also ensures accountability and helps identify patterns that could indicate emerging issues with the equipment.

Precautions for Handling Hazardous Materials

In some research environments, hazardous or biohazardous materials may be processed through freeze drying. In these cases, additional precautions must be observed. Chambers and condensers must be disinfected after each cycle, and users should wear appropriate protective equipment. The use of filters and sealed containers reduces the risk of contamination. Ventilation systems should ensure that no harmful vapors are released into the workspace. Clear labeling of hazardous samples is also necessary to avoid accidental exposure or improper disposal.

Environmental Considerations

Freeze drying systems often consume considerable amounts of energy due to refrigeration and vacuum requirements. To minimize environmental impact, efficient usage should be emphasized. This includes avoiding unnecessary overloading, optimizing drying cycles, and using energy-saving features when available. Safe disposal of contaminated pump oil and filters is another critical consideration. Laboratories should follow local regulations to dispose of waste responsibly, ensuring that solvents, oils, and biological residues do not contaminate the environment.

Risks and Preventive Measures in Freeze Drying

| Risk |

Potential Impact |

Preventive Measure |

| Vacuum Failure |

Incomplete drying, sample loss |

Regular pump maintenance and monitoring |

| Solvent Vapor Damage |

Pump corrosion or hazard |

Use of traps and proper ventilation |

| Temperature Deviation |

Sample structural damage |

Consistent monitoring and calibration |

| Cross-Contamination |

Compromised sample results |

Regular cleaning and sterilization |

| Electrical Fault |

Operator injury, equipment damage |

Inspection of wiring and grounding |

Integration of Freeze Drying Equipment into Laboratory Workflows

Precautions also include considering how freeze drying equipment is integrated into broader laboratory operations. Adequate space must be allocated not only for the equipment but also for sample preparation, storage, and handling. Emergency procedures should be established in case of equipment malfunction. Coordination with other laboratory systems, such as fume hoods or refrigeration units, should be considered for safety and efficiency. A holistic approach to integration reduces risks and increases the reliability of research outcomes.

Emergency Preparedness

Despite careful precautions, unexpected events can occur. Laboratories should establish emergency protocols for freeze drying operations. This may include procedures for dealing with vacuum leaks, power failures, or condenser overload. Fire safety protocols are particularly important when solvent-based samples are used. Emergency shutoff switches must be accessible, and staff should be trained in their use. A proactive approach to emergency preparedness minimizes the impact of unforeseen issues and enhances laboratory safety.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China