Introduction to Freeze Drying Beverages

Freeze-drying, or lyophilization, is a powerful method for preserving beverages while maintaining their flavor, nutrients, and aroma. This technique is widely used in industries ranging from coffee and tea to smoothies and sports drinks. The process removes moisture from the beverage while keeping its structure intact, resulting in a lightweight, shelf-stable product that can be easily rehydrated by simply adding water. Freeze-dried beverages have numerous benefits for consumers and manufacturers alike, including extended shelf life, improved portability, and ease of storage.

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd. is a leading innovator in freeze-drying technology. With a strong focus on combining advanced food science with intelligent equipment, Sieno delivers state-of-the-art beverages freeze-drying solutions that allow businesses to produce high-quality, freeze-dried beverages with enhanced preservation qualities. Whether you are looking to freeze-dry coffee, tea, juice, or other beverages, Sieno’s technology guarantees the highest levels of consistency and efficiency.

Benefits of Freeze Drying Beverages

Freeze-drying beverages provides several key benefits that make it a preferred method of preservation in various industries:

Preservation of Flavor and Aroma

Freeze-drying helps retain the original flavor and aroma of beverages better than other preservation methods, such as dehydration or canning. This is particularly important for high-quality products like coffee and tea, where flavor integrity is paramount. Sieno’s freeze-drying systems preserve the delicate compounds in beverages, ensuring that the rehydrated drink tastes as close to fresh as possible.

Extended Shelf Life

By removing moisture from beverages, freeze-drying significantly increases their shelf life. Freeze-dried beverages can last months or even years without refrigeration, making them ideal for products that need to be stored or transported for extended periods. Sieno’s advanced freeze-drying equipment provides an efficient and controlled process that ensures long-lasting quality and freshness.

Nutrient Retention

Freeze-drying helps retain the nutrients present in beverages, including vitamins and minerals, that are often lost during other drying methods. For example, freeze-dried fruit juices retain a high level of Vitamin C, while freeze-dried coffee retains antioxidants. Sieno’s technology ensures that the nutritional profile of the beverage remains intact after freeze-drying, providing consumers with a product that is both convenient and healthy.

Convenience and Portability

Freeze-dried beverages are lightweight, compact, and easy to store. This makes them ideal for consumers on the go, as they can easily be packed for outdoor activities, emergencies, or travel. Thanks to Sieno’s freeze-drying solutions, manufacturers can produce beverages that are easy to rehydrate and enjoy anywhere, from camping trips to space missions.

The Freeze-Drying Process for Beverages

Understanding the Science Behind Beverages Freeze Drying (Lyophilization)

Freeze-drying, also known as lyophilization, is a two-stage process. First, the beverage is frozen at extremely low temperatures, and then the ice is sublimated (converted directly from a solid to a gas) under a vacuum. This removes the water content while keeping the beverage’s structure and taste intact.

Step-by-Step Guide to Freeze Drying Beverages

1. Pre-treatment Before freeze-drying, beverages may be concentrated or pre-frozen to help the process proceed efficiently. Concentrating the beverage helps to reduce the total volume of water that needs to be sublimated, making the freeze-drying process faster.

2. Primary Drying (Sublimation) In this step, the frozen beverage is placed in a vacuum chamber, where the temperature and pressure are controlled to encourage sublimation. The ice in the beverage evaporates directly into vapor, leaving the rest of the beverage intact.

3. Secondary Drying (Desorption) During secondary drying, any remaining water vapor is removed. The product is gently heated to ensure that it is fully dry, and the texture remains light and crispy.

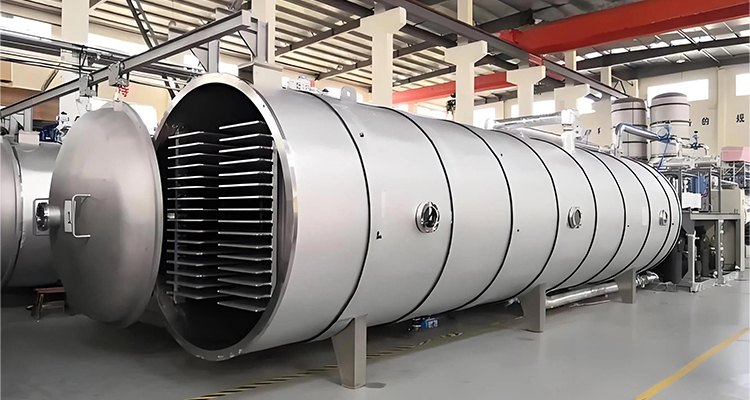

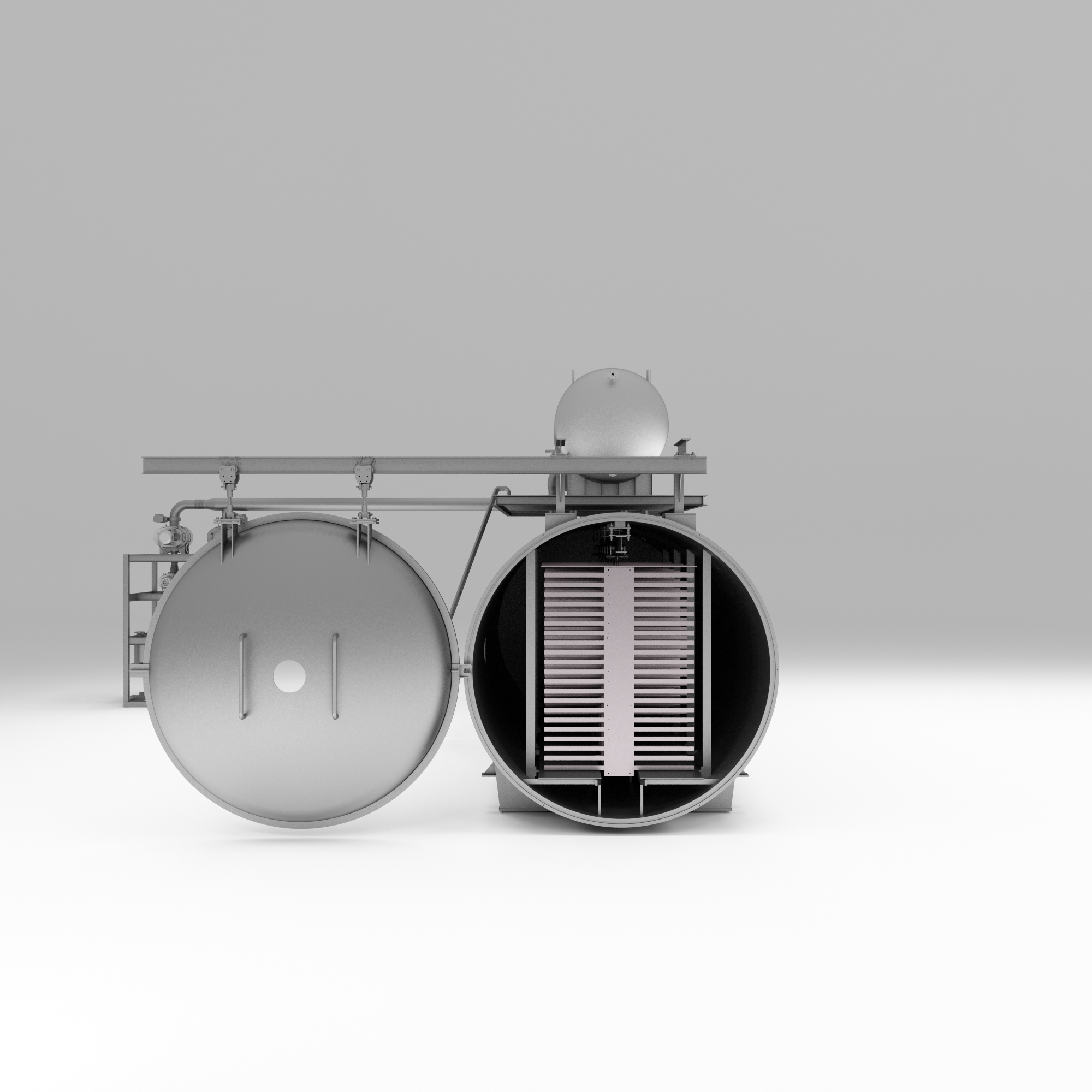

Equipment Used in Freeze Drying

The equipment used for freeze-drying beverages ranges from small-scale home freeze dryers to large-scale industrial freeze dryers. Sieno’s industrial-grade freeze-drying systems are designed to handle large volumes of beverages with precision, ensuring uniform drying and high-quality results. For smaller-scale operations, home freeze dryers offer a cost-effective solution for individuals or small businesses looking to produce freeze-dried beverages at home.

Types of Beverages Suitable for Freeze Drying

Coffee and Tea

Freeze-dried coffee and tea are some of the most common freeze-dried beverages on the market. The process helps preserve their aroma, flavor, and nutrients while extending their shelf life. Sieno’s technology ensures that the delicate compounds in both coffee and tea are retained during freeze-drying, allowing consumers to enjoy high-quality beverages at any time.

Juices and Smoothies

Juices and smoothies are popular choices for freeze-drying because the process preserves their freshness and nutritional value. For instance, freeze-dried orange juice retains much of the Vitamin C found in fresh juice, making it a nutritious, shelf-stable alternative. Sieno’s systems provide a consistent and efficient process for freeze-drying these beverages without compromising their texture or flavor.

Alcoholic Beverages

Although more complex, alcoholic beverages like wine or beer can also be freeze-dried. The freeze-dried form of alcohol can be used for various purposes, such as creating alcoholic drink mixes or novelty beverages. Sieno’s freeze-drying systems can be tailored to meet the unique requirements of freeze-drying alcoholic beverages, ensuring a consistent and high-quality product.

Milk and Dairy-Based Drinks

Freeze-drying milk and dairy-based drinks like chocolate milk or protein shakes preserves their creamy texture and nutritional content. This is especially valuable for creating shelf-stable dairy products that can be easily rehydrated. Sieno’s freeze-drying technology is optimized for dairy products, retaining the flavor and texture after rehydration.

Other Beverages (e.g., Sports Drinks, Energy Drinks)

Sports drinks, energy drinks, and similar beverages can be freeze-dried to maintain their electrolyte balance, flavor, and effectiveness over extended periods. Freeze-drying helps ensure these products are ready for quick consumption, especially in outdoor or emergency situations. Sieno’s advanced freeze-drying systems provide the optimal solution for freeze-drying these beverages while maintaining their quality.

Advantages and Disadvantages of Beverages Freeze-Drying

Pros

- Enhanced Shelf Life: Freeze-dried beverages last months or even years without refrigeration.

- Superior Flavor Retention: Freeze-drying preserves the original taste and aroma of beverages.

- Minimal Nutrient Loss: Freeze-dried beverages retain their nutritional content, including vitamins and antioxidants.

- Easy Storage and Transportation: Freeze-dried beverages are lightweight and easy to store or transport.

Cons

- Higher Initial Cost: Freeze-drying equipment can be expensive, especially for large-scale operations.

- Energy Consumption: The process requires a significant amount of energy to freeze and dry the beverages.

- Potential for Texture Changes: Some beverages may experience slight changes in texture after rehydration.

Applications of Freeze-Dried Beverages

Food Industry

Freeze-dried beverages are commonly used in the food industry for creating instant drinks, flavored water, and convenient beverage mixes. Manufacturers can utilize Sieno’s freeze-drying solutions to produce high-quality, shelf-stable products.

Military and Emergency Preparedness

Freeze-dried beverages are ideal for military rations and emergency preparedness kits, where portability, shelf life, and ease of rehydration are essential.

Outdoor Activities (Camping, Hiking)

Freeze-dried beverages are popular among campers, hikers, and outdoor enthusiasts for their convenience and lightweight nature. Sieno’s technology ensures that the freeze-dried beverages retain their flavor and nutritional value, even after long storage.

Space Exploration

In space, astronauts rely on freeze-dried beverages due to the lack of refrigeration and limited storage space. Freeze-dried beverages offer a compact, nutrient-rich solution for space missions.

How to Rehydrate Freeze-Dried Beverages

Best Practices for Rehydration

1. Use Clean, Filtered Water: Water quality is critical for achieving the best taste. Avoid tap water that may contain chlorine or other contaminants.

2. Follow the Recommended Water-to-Beverage Ratio: Using the right water-to-powder ratio ensures the beverage is not too diluted or concentrated.

3. Adjust Water Temperature Based on Beverage Type: Use cold water for juice or smoothies and hot water for coffee and tea.

4. Stir Well for Even Rehydration: Stirring ensures the beverage rehydrates uniformly, avoiding clumps or uneven texture.

5. Let It Sit for a Few Moments: Allow the beverage to sit for a minute or two after stirring to ensure full rehydration.

Tips for Achieving Optimal Flavor and Texture

1. Experiment with Water-to-Powder Ratio: Adjust the ratio to suit your taste preferences, depending on whether you want a stronger or milder flavor.

2. Rehydrate in Small Batches: Rehydrating small amounts ensures that you can fine-tune the flavor and texture before making larger quantities.

3. Consider Adding Other Ingredients: Add fresh ingredients like fruit, honey, or milk alternatives to enhance flavor.

4. Rehydrate with Milk or Plant-Based Alternatives: For creamier texture, use milk or plant-based milk instead of water when rehydrating smoothies or coffee.

5. Consider Temperature for Texture: Avoid using water that’s too hot for beverages like milk-based drinks, which could alter their texture.

Parameter Comparison: Rehydration Process

| Beverage Type |

Water Temperature |

Rehydration Time |

Recommended Water-to-Powder Ratio |

Texture After Rehydration |

| Freeze-Dried Coffee |

Hot water (190°F - 205°F) |

1-2 minutes |

1 part coffee to 3-4 parts water |

Smooth and rich |

| Freeze-Dried Tea |

Hot water (170°F - 200°F) |

1-2 minutes |

1 part tea to 3-4 parts water |

Aromatic and refreshing |

| Freeze-Dried Juice |

Cold water or ice water |

2-3 minutes |

1 part juice powder to 3 parts water |

Fresh and flavorful |

| Freeze-Dried Smoothies |

Cold water or milk |

2-3 minutes |

1 part smoothie powder to 3 parts liquid |

Creamy and smooth |

| Freeze-Dried Protein Shakes |

Cold water or milk |

2-3 minutes |

1 part powder to 3-4 parts liquid |

Thick and well-mixed |

English

English  русский

русский  中文简体

中文简体

+86- (0) 519-8578 6988

+86- (0) 519-8578 6988  +86-180 6875 7376

+86-180 6875 7376  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China