What are the investment costs and operating energy consumption of freeze-drying equipment for tea beverages?

Initial Investment Costs of Freeze-Drying Equipment for Tea Beverages

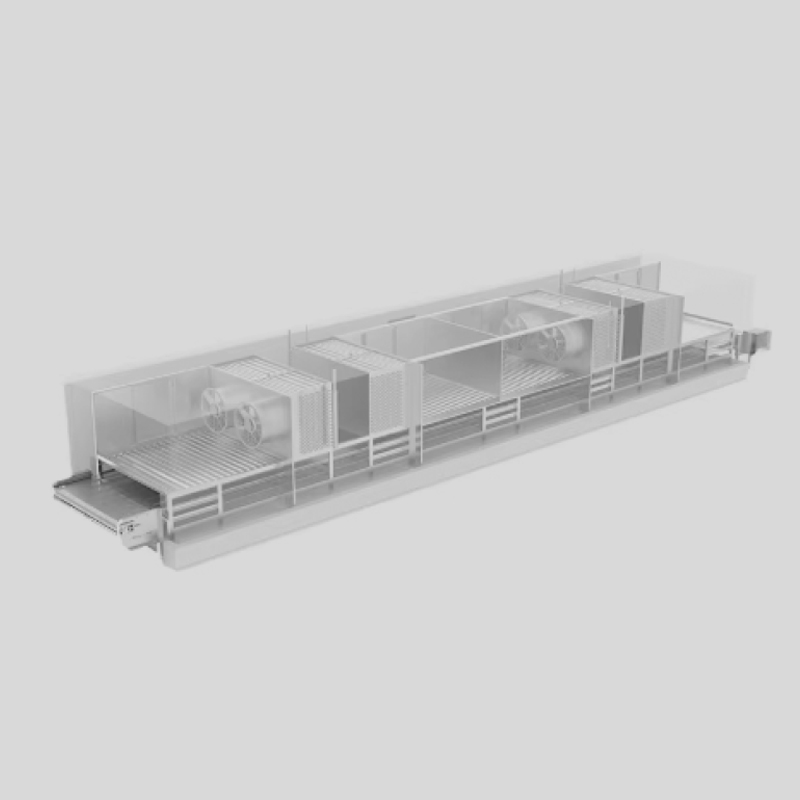

The investment required for freeze-drying equipment used in tea beverage production is influenced by machine scale, technological features, and level of automation. Smaller systems designed for pilot projects or research applications require relatively modest investment, while large-scale industrial units capable of handling continuous production represent a higher financial commitment. Investors should also account for the costs of installation, facility adaptation, and auxiliary equipment such as vacuum pumps, refrigeration systems, and control units. A clear understanding of capital requirements ensures that businesses can align budget planning with expected production volumes.

Breakdown of Major Cost Components

When evaluating investment in freeze-drying equipment for tea beverages, it is useful to identify specific cost components. These include the main chamber, refrigeration units, vacuum pumps, automation systems, and construction materials. Additional expenses may arise from software integration for monitoring and control. Costs can also vary depending on whether the system is designed for batch or continuous operation. The following table provides a general overview of cost components and their relative significance:

| Component | Relative Cost Share | Influence on Overall Budget |

|---|---|---|

| Main Chamber | 25–30% | Determines capacity and durability |

| Refrigeration Units | 15–20% | Critical for maintaining low temperatures |

| Vacuum Pumps | 10–15% | Ensures stable sublimation process |

| Automation & Control | 10–20% | Supports precision and efficiency |

| Auxiliary Systems | 5–10% | Includes trays, condensers, and sensors |

Cost Differences Between Pilot and Industrial Scale

The cost of freeze-drying equipment for tea beverages differs considerably between pilot-scale and industrial-scale units. Pilot systems are often used for product testing, recipe development, and small-scale production, costing less due to smaller capacity and simplified components. Industrial-scale systems, on the other hand, are designed to operate continuously, integrate advanced automation, and handle larger product loads, which significantly increases investment. Companies must carefully evaluate their expected production volume and market demand before choosing between pilot and industrial units to ensure that investment is proportionate to revenue expectations.

Operating Energy Consumption of Freeze-Drying Equipment

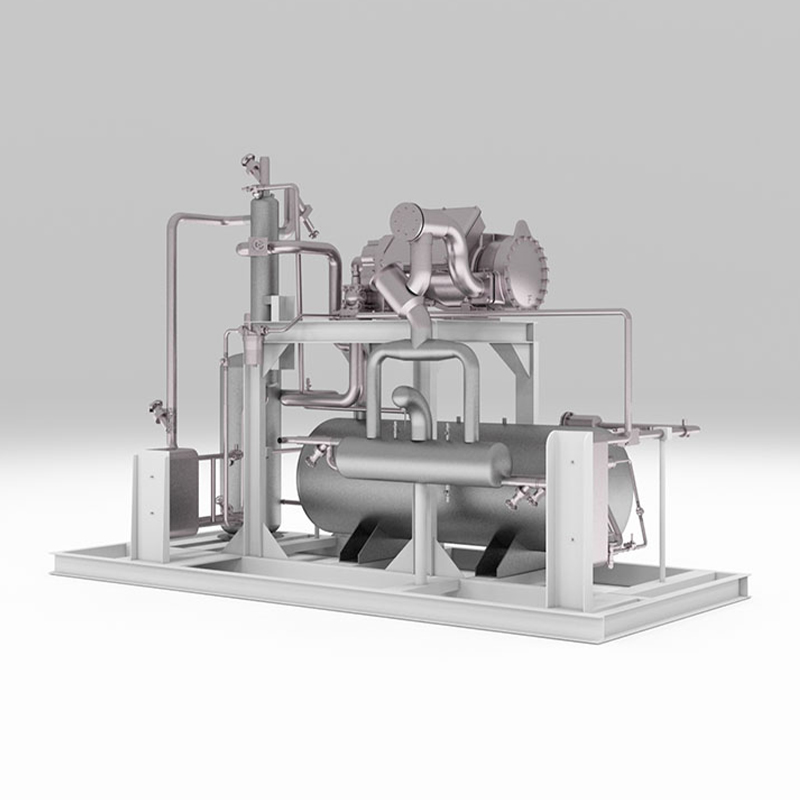

Operating energy consumption is a crucial factor in freeze-drying tea beverages. The process requires refrigeration to achieve low product temperatures, as well as vacuum generation to enable sublimation. These systems collectively consume substantial energy, particularly when processing large batches. Energy use is also influenced by drying cycle length, product moisture content, and ambient operating conditions. Monitoring and managing energy consumption helps producers balance operational costs with the benefits of high-quality freeze-dried tea products.

Key Energy-Consuming Components

The energy profile of freeze-drying equipment is determined by several components. Refrigeration units consume energy to maintain extremely low temperatures required for freezing and sublimation. Vacuum pumps draw energy to sustain stable low-pressure conditions. Heating systems, which provide controlled heat for sublimation, also contribute to energy usage. Automation and monitoring systems consume relatively less power but still add to total operating costs. The distribution of energy consumption among these components can be illustrated as follows:

| Component | Energy Contribution | Operational Role |

|---|---|---|

| Refrigeration System | 40–50% | Maintains freezing and condenser temperature |

| Vacuum Pump | 25–30% | Provides low-pressure environment |

| Heating System | 15–20% | Supports sublimation phase |

| Control & Automation | 5–10% | Regulates and monitors operations |

Influence of Batch Size on Energy Consumption

The energy efficiency of freeze-drying tea beverages depends heavily on batch size. Running small batches in large equipment often leads to inefficient energy use, as refrigeration and vacuum systems must still operate at full capacity regardless of load. Conversely, operating the equipment at or near full capacity distributes energy consumption more effectively across the processed volume. Planning production schedules to optimize batch size is therefore an important strategy for managing energy costs.

Automation and Energy Efficiency

Automation systems in freeze-drying equipment for tea beverages contribute to energy efficiency by ensuring precise control of process parameters. Automated control adjusts temperature, pressure, and heating phases in real-time, reducing unnecessary energy use. In addition, predictive maintenance features can detect inefficiencies early, such as vacuum leaks or refrigeration imbalances, which would otherwise increase energy consumption. The upfront investment in automation can lead to reduced operational costs over the long term, balancing initial capital expenditure with energy savings.

Comparison with Conventional Drying and Freezing

Freeze-drying tea beverages generally requires higher investment and energy consumption compared to conventional drying or freezing. Conventional drying methods such as hot air drying consume less energy but may compromise product quality. Freezing alone is less energy-intensive than freeze-drying but does not achieve the same shelf life or preservation of tea’s sensory qualities. Businesses evaluating the adoption of freeze-drying must weigh higher energy and investment requirements against the enhanced market value of freeze-dried tea beverages.

Energy Consumption Trends Over Time

Energy consumption during freeze-drying is not constant; it varies across different stages of the process. Initially, the refrigeration system consumes significant energy to freeze the product. During sublimation, vacuum pumps and heating systems become the dominant energy users. In the final drying stage, energy demand may decrease slightly but remains substantial. Understanding these trends helps operators plan energy use and explore opportunities for optimization, such as recovering waste heat or scheduling operations during lower-cost electricity periods.

Maintenance Costs and Their Link to Energy Use

Maintenance plays an important role in controlling both investment returns and energy consumption. Poorly maintained equipment often consumes more energy due to inefficiencies in vacuum pumps, refrigeration leaks, or worn seals. Regular inspection, cleaning, and timely replacement of parts ensure that the system operates at designed energy efficiency levels. Although maintenance requires additional cost, it prevents larger expenses associated with excessive energy use and unplanned downtime.

Environmental Considerations Related to Energy Use

Energy consumption of freeze-drying equipment for tea beverages also has environmental implications. Higher electricity demand contributes to increased carbon emissions unless renewable energy sources are used. Companies focused on sustainability may explore energy recovery systems or integrate renewable energy solutions into their facilities. These practices not only reduce environmental impact but also improve brand reputation in markets where sustainability is a priority.

Investment Return Analysis

When analyzing investment in freeze-drying equipment, it is necessary to evaluate return on investment in relation to both costs and potential revenue. Higher upfront expenditure is balanced by the premium value of freeze-dried tea products in the market, which can command higher prices due to preserved aroma, flavor, and shelf life. Operating energy consumption reduces net profit margins, but careful optimization of production schedules and equipment use can mitigate these costs. Businesses that strategically manage both investment and operational expenses are more likely to achieve favorable returns.

Cost and Energy Comparison Table

The following table provides a simplified comparison of investment and operating energy consumption for freeze-drying equipment versus conventional alternatives:

| Method | Investment Cost | Operating Energy Consumption | Product Quality |

|---|---|---|---|

| Freeze-Drying | High | High | High retention of aroma and flavor |

| Conventional Drying | Low | Low | Moderate, with loss of delicate notes |

| Freezing | Medium | Medium | Limited preservation |

Strategies to Optimize Energy Use

To reduce operating energy costs, businesses can adopt several strategies. These include scheduling production during off-peak electricity hours, using batch sizes that maximize equipment capacity, and maintaining refrigeration and vacuum systems for peak efficiency. Additionally, investing in heat recovery or energy-efficient components helps reduce consumption. Over time, these measures significantly improve cost management and operational sustainability.

Scalability and Future Expansion Considerations

Another factor in investment decisions is scalability. Businesses entering the tea beverage freeze-drying market may start with smaller equipment and later expand capacity. While smaller systems reduce initial costs, scaling up may require reinvestment in larger equipment. Choosing modular systems that can be expanded with additional chambers or automation units offers a balance between managing investment risk and preparing for future growth. Energy consumption also scales with equipment size, so efficient system design is essential for long-term sustainability.

Conclusion of Comparative Factors

The investment costs and operating energy consumption of freeze-drying equipment for tea beverages present both challenges and opportunities. Higher upfront and operational expenses are offset by the value added to the final product and the ability to meet consumer demand for premium, long-lasting tea beverages. By carefully analyzing equipment design, energy management strategies, and production planning, businesses can align investment with long-term profitability while addressing environmental considerations linked to energy use.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China