Introduction to Food Freeze Drying

What is Food Freeze Drying?

Food Freeze Drying, also known as Lyophilization, is a high-precision dehydration preservation technique. The principle utilizes the phenomenon of sublimation: water-containing food is first thoroughly frozen below its freezing point (solid state), and then, in a vacuum environment, the solid ice is directly converted into water vapor (gas), bypassing the liquid state. This process removes up to 98% of the moisture from the food. Because the process is carried out at low temperatures, the cellular structure of the food is preserved to the maximum extent, ensuring that it can be restored to near its original state upon rehydration.

Brief History and Evolution

Freeze drying technology originally dates back to World War II, where it was primarily used to preserve heat-sensitive biological materials, such as blood plasma and pharmaceuticals. After the war, it was adopted by NASA for the development of astronaut rations, capitalizing on the light weight and long shelf life of freeze-dried foods. As the technology matured and costs decreased, freeze dryers gradually moved from small laboratory and military applications into the civilian and commercial food processing sectors. Today, innovative companies, represented by Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd, are dedicated to introducing professional intelligent freeze-drying equipment and customized solutions into the food industry, driving the innovation and upgrading of food processing and modern production technologies.

Benefits of Freeze Drying Food

Food freeze drying offers advantages over traditional preservation methods, mainly in the following areas:

- Extended Shelf Life:

- Details: By removing almost all moisture (moisture content reduced to 1% - 4%), microbial growth and enzyme activity are effectively inhibited.

- Parameter: With proper storage, the shelf life of freeze-dried food can extend from 15 to 25 years.

- Nutrient Retention:

- Details: Freeze drying occurs at extremely low temperatures and under vacuum, avoiding the high heat involved in traditional dehydration or canning.

- Parameter: Retention rates for heat-sensitive nutrients like vitamins and antioxidants typically reach 90% to 97%.

- Flavor Preservation:

- Details: The low temperature and low pressure environment effectively lock in the food's volatile flavor compounds and original color, ensuring that the taste and texture upon rehydration closely resemble fresh food.

- Convenience and Portability:

- Details: Freeze-dried food is extremely light, typically only about 10% of its original weight, making it highly portable and ideal for travel, emergency, and outdoor use.

The Science Behind Freeze Drying

Understanding Sublimation

Sublimation is the core physical phenomenon of the freeze-drying process. It is the direct transition of a substance from the solid state (ice) to the gaseous state (water vapor), bypassing the liquid phase. To achieve sublimation, two critical parameters must be met:

- Vacuum Condition: The pressure inside the freeze-drying chamber must be extremely low, below the triple point pressure of water (0.006 atm or 4.58 Torr).

- Temperature Control: The ice temperature must be maintained below the triple point temperature.

Under these strict parametric controls, the vapor pressure of the ice exceeds the chamber pressure, driving the ice crystals to convert into gas and be captured by the condenser. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd ensures the stability and efficiency of the sublimation process through its high-precision vacuum pump systems.

The Freeze-Drying Process: Step-by-Step

The freeze-drying process is divided into three precisely controlled phases, which are highly automated through advanced control systems on intelligent freeze-drying equipment developed by companies like Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd.

- Step 1: Freezing

- Details: Food is rapidly and uniformly frozen below its critical temperature (typically -40∘C to -50∘C). This step is crucial as it determines the size and structure of the ice crystals.

- Sieno Value: Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd, through its strategic collaborations in food science, recommends that users precisely control the freezing rate to form optimal ice crystal structures and thus optimize drying efficiency.

- Step 2: Primary Drying (Sublimation)

- Details: Under high vacuum (very low pressure), the shelves begin to heat slowly. Thermal energy facilitates the sublimation of ice crystals. Water vapor is constantly removed from the food and transferred to the extremely cold condenser (typically below -50∘C). This is the longest stage, designed to remove 95% of the moisture.

- Step 3: Secondary Drying (Desorption)

- Details: After primary drying, a small amount of bound water (around 1% to 5%) remains attached to the solid structure of the food. At this point, the temperature is slowly raised, and the residual moisture is removed through desorption, reducing the final moisture content to 1% to 4%, which is necessary for long-term preservation.

Factors Affecting the Freeze-Drying Process

The efficiency and quality of the freeze-drying process are directly influenced by a variety of intrinsic and extrinsic factors.

| Affecting Factor |

Detailed Description |

Impact on Freeze-Drying Efficiency/Quality |

| Critical Temperature |

The maximum safe temperature the food can withstand in its frozen state. |

Restricts the maximum shelf heating temperature to prevent structure collapse. |

| Food Geometry |

The size and thickness of the food pieces. |

Small pieces or slices can significantly shorten the water vapor path, increasing efficiency. |

| Initial Moisture Content |

The total water content of the food before freeze drying. |

Higher initial moisture content leads to a longer cycle time. |

| Equipment Performance |

The ultimate vacuum degree of the vacuum pump and the ice-holding capacity of the condenser. |

High-performance equipment ensures a more stable environment and shortens the total cycle. |

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd, through its in-depth exploration of freeze-dried food science, emphasizes the importance of accurately determining the critical temperature for developing efficient freeze-drying protocols.

Equipment for Home Freeze Drying

Types of Freeze Dryers for Home Use

Equipment used for home and small commercial purposes is mainly categorized by its internal operation:

- Tray Freeze Dryers:

- Details: This is the most common type for home and small commercial use. Food is placed uniformly on multiple layers of metal trays, which rest on heated shelves. Heat is transferred by conduction to facilitate sublimation.

- Features: Robust structure, flexible operation, with precise temperature and program control functions.

- Rotary Freeze Dryers:

- Details: Primarily designed for laboratory research or processing liquid, paste, or powder samples. The container rotates to increase surface area and accelerate sublimation.

- Features: Less common in large-scale food freeze drying or home use, focuses more on R&D and process validation.

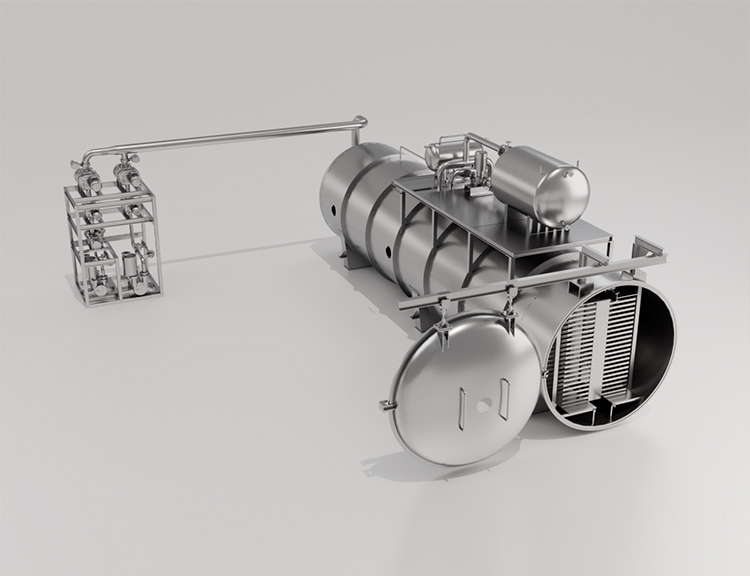

Components of a Freeze-Drying System

A freeze-drying system is a highly integrated unit combining refrigeration, vacuum, and heating technologies. Here are its three most critical components and their parameters:

| Core Component |

Primary Function |

Key Parameter Details |

| Vacuum Pump |

Generates and maintains the extremely low pressure environment required for freeze drying, ensuring continuous sublimation. |

Ultimate Vacuum: Typically required to be below 100 mTorr (0.133 mbar) for efficient sublimation. |

| Condenser |

Captures water vapor, protects the vacuum pump, and maintains the chamber vacuum. |

Minimum Temperature: Usually between -40∘C and -85∘C.. Lower temperature means stronger ice-holding capacity and faster drying. |

| Heating System |

Supplies precisely controlled thermal energy to the food via the shelves during the drying phases. |

Shelf Temperature Range: Determines the flexibility of the drying program settings, especially during secondary drying. |

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd consistently focuses on exploring the profound integration of freeze-drying equipment and intelligent manufacturing technology to ensure these core parameters meet high-efficiency and stable operation standards.

Choosing the Right Freeze Dryer

When selecting a freeze dryer suitable for home or small commercial use, a comprehensive assessment of needs and equipment technical parameters is necessary.

| Key Factor |

Detailed Description |

Decision Point |

| Capacity |

Assess your required average batch size (calculated as kg of wet weight per day). |

Higher capacity means a higher throughput per batch but also a higher initial purchase cost. |

| Features |

Consider whether additional features are needed, such as an oil-free (dry) vacuum pump, intelligent remote monitoring, or automatic defrost. |

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd offers independently developed intelligent freeze-drying equipment that supports precise programming and monitoring. |

| Budget |

The initial investment should cover the price of the machine itself and the cost of the pump options. |

Focus on the overall value provided by the equipment over a long-term preservation period of 15 to 25 years, rather than just the initial cost. |

Best Foods to Freeze Dry

Fruits

Fruits generally yield excellent freeze-drying results due to their high sugar content and stable cellular structure, retaining maximum crispness and sweetness.

- Berries: Strawberries, Blueberries, Raspberries. These fruits have a small, intact structure, maintaining perfect shape and crispness after freeze drying.

- Sliced Fruits: Bananas, Apples. These should be cut into uniform slices or small pieces. A simple pretreatment (such as a brief soak in lemon water) can be considered to prevent browning.

Vegetables

Freeze-dried vegetables are great for soups, stews, and emergency rations. Most vegetables require pretreatment before freeze drying to ensure long-term storage quality.

- Small Particle Vegetables: Peas, Carrots, Corn. These vegetables usually require blanching (briefly scalding in boiling water) beforehand.

- Blanching Requirement: The purpose of blanching is to inactivate the enzymes present in the vegetables. If enzymes are not inactivated, they can cause the vegetables to discolor, develop off-flavors, or lose nutritional value even during storage after freeze drying.

- Other Vegetables: Broccoli, cauliflower, bell peppers. Should be cut into small florets or pieces after pretreatment.

Meats and Seafood

Meats and seafood are high-value freeze-dried foods, but their pretreatment requirements are strict due to food safety.

- Safety Requirement: All meats (such as Chicken, Beef) and seafood (such as Shrimp) must be thoroughly cooked before freeze drying. The freeze-drying process is not a sterilization process; it only puts microorganisms and bacteria into a dormant state.

- Preparation Form: Cooked meat should be cut into uniform small pieces, strips, or ground to maximize surface area and ensure moisture is removed efficiently and uniformly during the freeze-drying process.

- Fat Limitation: Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd advises users to remove visible fat before freeze drying. High fat content hinders water sublimation, reduces drying efficiency, and shortens the product's shelf life due to easy oxidation.

Dairy Products and Complete Meals

Freeze drying technology is also suitable for complex foods and dairy products, but special handling is required.

- Dairy Products: Cheese (non-high-oil types), Yogurt, Ice Cream. Yogurt and ice cream need to be flattened or formed into small drops before freeze drying.

- Complete Meals: Soups, Stews, Casseroles. These meals can be freeze-dried, usually by first freezing them in thin layers or small chunks.

- Freeze-Drying Challenge Parameter: The biggest challenge for complete meals is the fat content. Recipes with low fat content should be chosen, otherwise drying effectiveness is poor and the food is prone to oxidative spoilage during long-term storage. Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd offers customized solutions for customers seeking the highest efficiency and quality, guiding them to optimize complex food formulations.

Tips and Tricks for Successful Freeze Drying

Optimizing Freeze-Drying Time

Successful freeze drying relies on precise management of time and efficiency. Following these tips can effectively reduce the freeze-drying cycle time:

| Tip |

Detailed Description |

Efficiency Improvement Parameter |

| Uniform Food Size |

Cut all food to be freeze-dried into uniform sizes, ideally no thicker than 1 cm (approx. 0.4 inches). |

Ensures consistent sublimation rate for all materials, preventing under-drying of some, and thus shortening the total cycle. |

| Thorough Pre-freezing |

Pre-freeze the food to the lowest possible temperature in an external freezer before placing it in the freeze dryer. |

Reduces the initial load on the freeze dryer's condenser, which can reduce cycle time by 4 to 8 hours depending on the material. |

| Appropriate Tray Spacing |

Avoid overcrowding the trays; ensure sufficient space between food items. |

Guarantees that water vapor can escape freely and quickly from the food surface to be captured by the condenser. |

Preventing Common Problems

During the freeze-drying process, several common issues may arise that affect the quality and storability of the final product.

- Moisture Issues:

- Details: The food tastes chewy instead of crispy after the freeze-drying cycle, indicating that the moisture content is still too high.

- Prevention: Extend the secondary drying time, or slightly increase the secondary drying temperature within the program's safe parameters.

- Uneven Drying:

- Details: Some food pieces are crispy, while others remain soft.

- Prevention: Ensure uniform food size. Mid-cycle during primary drying, manually (or programmatically) rotate or change the position of the trays to compensate for potential minor temperature variations within the freeze-drying chamber.

Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd is committed to providing customers with intelligent freeze-drying equipment that supports precise programming and monitoring, allowing for better handling of the drying challenges posed by complex ingredients.

Enhancing Flavor and Texture

While freeze drying primarily focuses on preservation, proper preparation can further enhance the flavor and texture upon rehydration.

- Pre-cooking Seasoning: Freeze drying locks in the existing flavor. For cooked meats and broths, it is advisable to lightly season them before freeze drying to ensure better flavor upon rehydration.

- Fat Management: Sieno Freeze-drying Technology Research Institute (Jiangsu) Co., Ltd strongly recommends removing visible fat before freeze drying. High fat content hinders water sublimation and significantly shortens the product's shelf life because fats are highly prone to oxidation.

- Rehydration Agent Selection: Freeze-dried food will absorb any liquid. Using broth or stock instead of plain water for rehydration can reintroduce nutrients and flavor to the food, enhancing the final eating experience.

Safety Precautions

Food safety remains the top priority, regardless of the freeze-drying equipment used.

- Microbiological Safety:

- Details: The freeze-drying process (low temperature and vacuum) is not a sterilization process; it only puts microorganisms and bacteria into a dormant state.

- Requirement: All foods that can harbor pathogens, especially meats, seafood, and eggs, must be thoroughly cooked before freeze drying.

- Equipment Operation Safety:

- Details: Always strictly follow the equipment manual. When handling the extremely cold condenser and the heated shelves, appropriate protective gloves must be worn.

- Solvent Risk:

- Details: Home freeze dryers are mainly designed for water-based samples. Handling samples containing alcohol or complex solvents may require professional equipment with lower condenser temperatures and specific ventilation requirements.

Freeze-Dried Food Recipes

Breakfast Ideas

Freeze-dried foods offer efficient and nutritious breakfast options for a fast-paced lifestyle.

- Freeze-Dried Fruit and Yogurt Parfait:

- Preparation Details: Layer freeze-dried berries (e.g., strawberries, blueberries) or banana slices with yogurt and granola.

- Consumption Method: The freeze-dried fruit requires no extra rehydration; it absorbs the small amount of moisture from the yogurt, maintaining a crispy texture.

- Freeze-Dried Smoothie Packs:

- Preparation Details: Mix various freeze-dried fruit powders, vegetable powders, and a small amount of protein or whey powder in a sealed bag.

- Consumption Method: Simply add water, milk, or juice, shake, or blend to create a quick smoothie.

Lunch and Dinner Ideas

Freeze-dried cooked meals are ideal for emergency rations or outdoor dining, capable of quickly restoring a balanced and nutritious meal.

- Freeze-Dried Chicken and Vegetable Stew:

- Preparation Details: Mix thoroughly pre-cooked and freeze-dried chicken cubes, carrot slices, and potato pieces.

- Rehydration Parameter: Add hot water or hot stock, and let it soak for 10 to 15 minutes. The hot liquid accelerates the rehydration process of the freeze-dried ingredients.

English

English  русский

русский  中文简体

中文简体

+86-180 6875 7376

+86-180 6875 7376  +86- (0) 519-8578 6988

+86- (0) 519-8578 6988  emmy@jsblk.com

emmy@jsblk.com  Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China